Celio: Efficient Store Delivery with the Split Tray Sorter

Celio was founded in 1978 by Marc and Laurent Grosman and has since grown into a worldwide leader in men’s fashion, with over 1,500 stores in more than 60 countries. The company offers a wide selection of sustainable men’s fashion for every age group and style. Celio also introduced a women’s fashion line in 2024 under the brand Be Camaïeu.

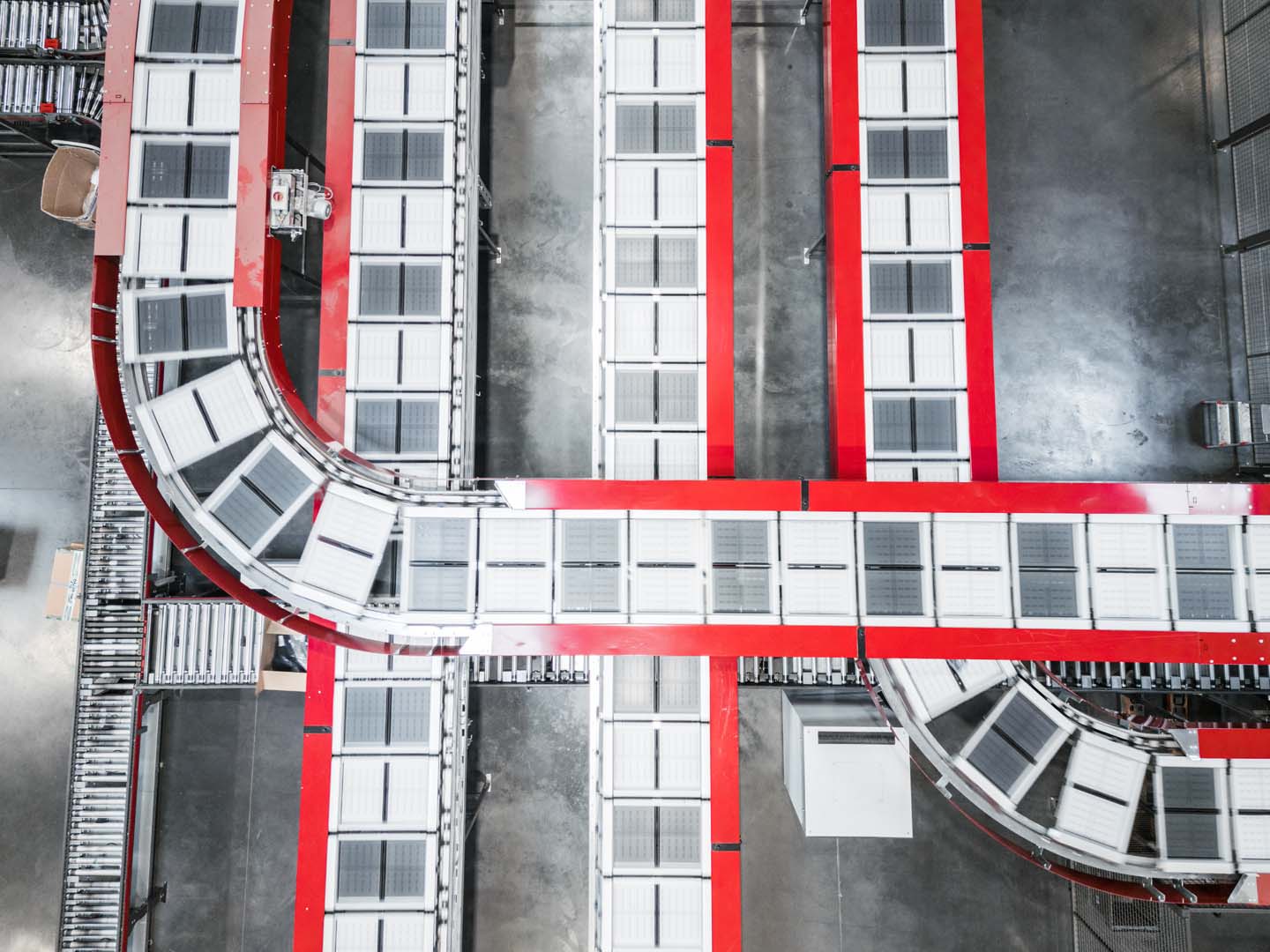

In 2012, Celio opened a new logistics center in Amblainville, consolidating three former Celio warehouses into one location to improve the logistics of supplying their stores. Today, the split tray sorter and upstream shuttle continue to work together to form the heart of the solution. Thanks to this combination of technology, Celio is able to minimize their logistics costs and create sustainable value for their customers.

15,000 items per hour

7 halls, each 6,000 m² (64,600 ft²)

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWe provided Celio with a powerful, comprehensive solution from a single source.

Eric Pineau

Software Engineering, KNAPP France

Would you like to re-align your value chain?

Contact our experts today.

Goals accomplished

Reduced costs

Increased efficiency

Simplified processes

Increased precision

Improved working conditions

More competitive

Would you like to re-align your value chain?

Contact our experts today.

Successful store delivery

1) Efficient presorting

When an order requires the content of a full case, it is retrieved from the pallet warehouse and transported to the right induction island. For partial quantities, items are taken from storage cartons or containers and presorted into transport containers. These are then transported to the corresponding induction island. Split cases are repacked by SKU unmixed into storage containers and buffered in the shuttle system.

2) Manual loading

At one of the four induction islands at the split tray sorter, incoming goods are placed directly on the sorter and automatically scanned as they pass through a manual loading station. Should a reading fail, the product is diverted to a specific location to be read and corrected manually and then placed back on the sorter.

3) Automatic sorting

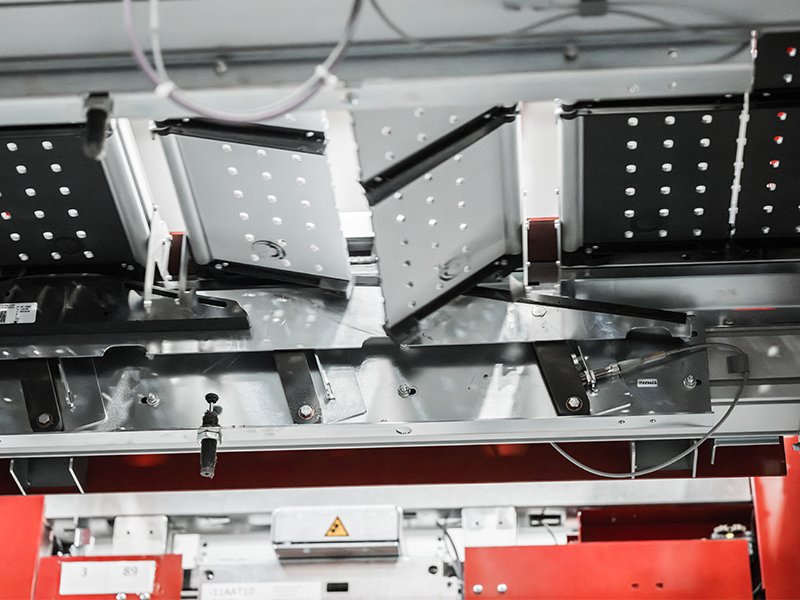

The goods are sorted by the split tray sorter, which comprises transport carriers connected together on a horizontal plane. At the target location, the tray opens and the products fall into cartons or containers. Alternatively, products are discharged to a chute. The two tray flaps open independently of each other, allowing two separate products to be sorted to different targets. Larger products can be placed across the entire tray. The system automatically detects them and opens both tray flaps simultaneously at the target position.

4) On to the store

At Celio, correctly read products are released at their target release points into shipping cartons or containers. Full shipping cartons are automatically displayed and manually pushed onto the discharge lane, from where they are transported to the shipping sorter. The sorter sorts them onto one of 10 lanes according to the region. This efficient goods movement process ensures that items always take the shortest route to the induction island and to their target.

We are very pleased that the sorter still works as well as it did on day one.

Gérald Le Boulaire

Warehouse Manager, Celio

The split tray sorter: A must-have for flat-packed goods

When high-performance sorting of flat-packed goods is required, the split tray sorter is an optimal solution, and this was the case for Celio. Thanks to its meandering system design featuring eight parallel lanes above a total of 688 target locations, the Amblainville logistics center has achieved maximum performance in a minimum of space. More orders can be shipped completely and punctually.

outlets on the split tray sorter

items per hour

m² (64,600 ft²) storage space

double trays on the split tray sorter

Importance of ergonomics

One particular aim was to improve working conditions for the employees using ergonomically designed work stations. For this purpose, we allowed Celio to give our work stations a test drive. This intensive focus on workplace ergonomics and its successful implementation at Celio resulted in an increase in performance and low staff turnover.

Our expectations for performance, ergonomics and noise levels were fully met. Training users is fast and easy.

Gérald Le Boulaire

Warehouse Manager, Celio