Pocket Sorter Module: PocketEngine

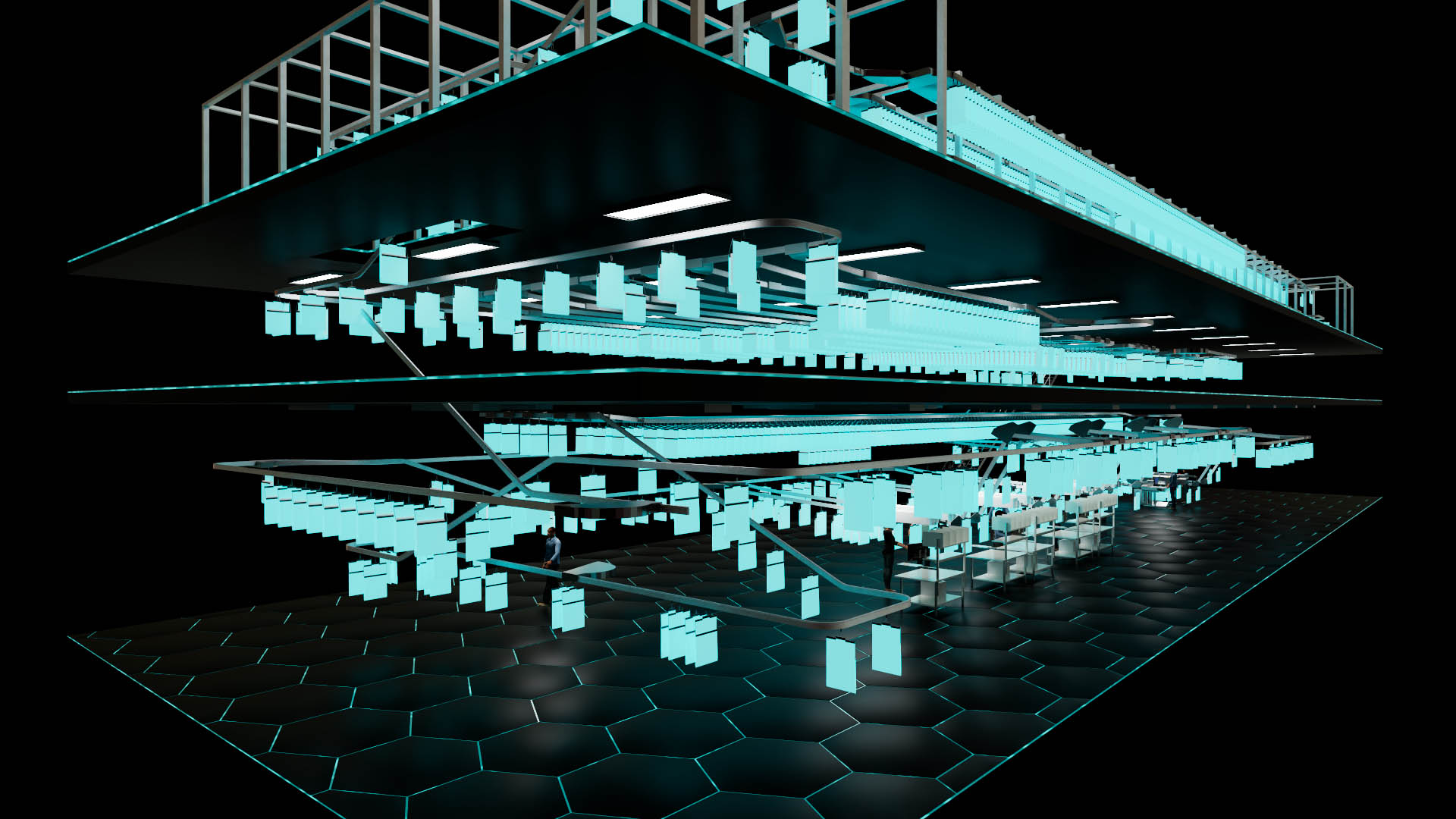

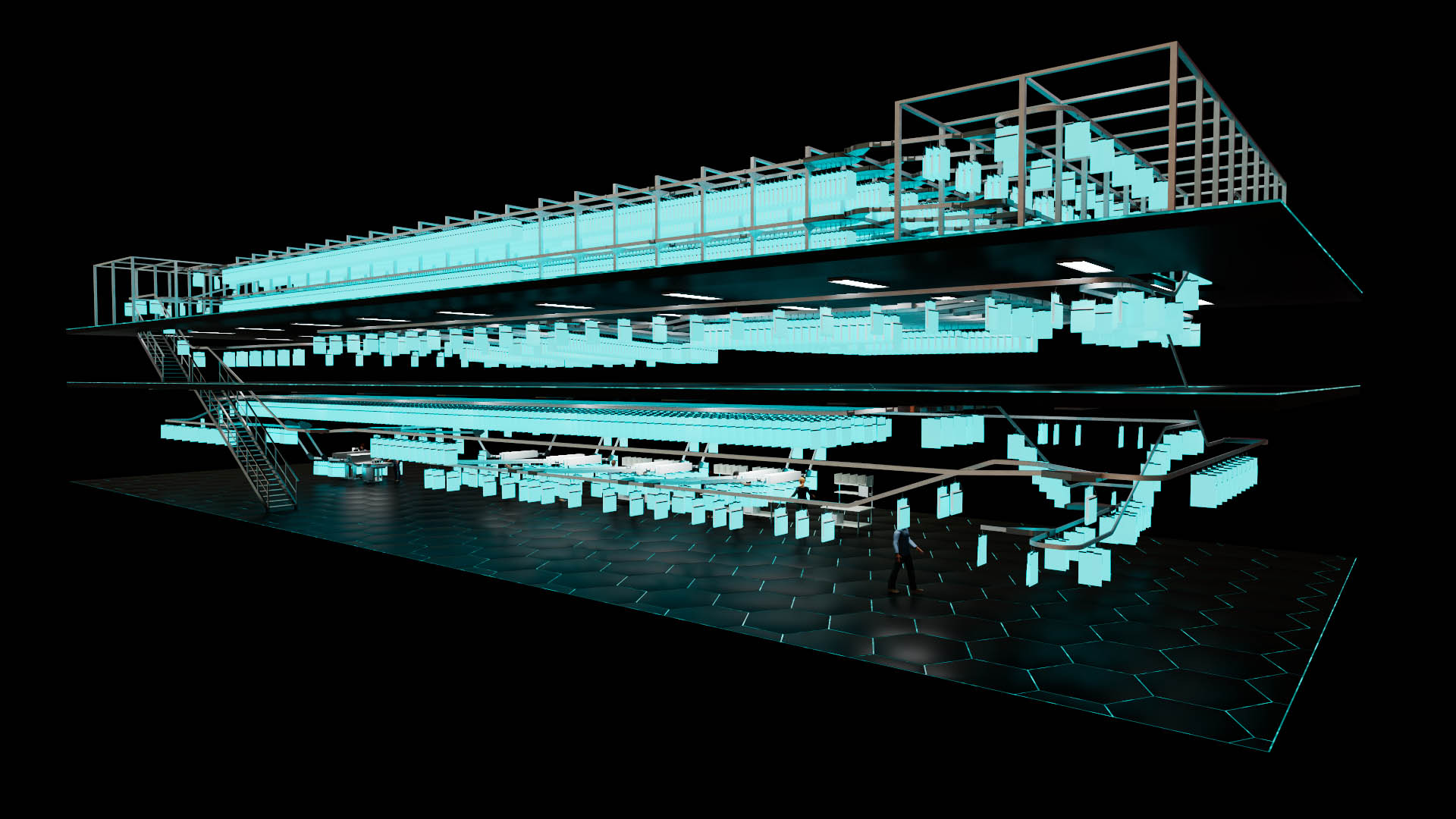

PocketEngine is a standardized, three-story pocket sorter module for buffering, sorting and picking items from all areas of the warehouse. The system is the perfect choice for e-commerce fulfillment, store fulfillment or returns management. Thanks to a separate consolidation buffer and sequencing sorter, goods from different areas of the warehouse can be processed together.

PocketEngine redefines pocket sorter systems

Are you looking for an all-in-one solution for processing your e-commerce orders? Are sequencing and sorting essential parts of your order fulfillment? Have you had enough of dealing with the never-ending stream of returns?

With PocketEngine, we’ve got exactly what you’re looking for. Designed to amply fulfill the requirements of e-commerce, store fulfillment and returns management, the pocket sorter system efficiently consolidates, sorts and sequences different goods from all over the warehouse. The system also automatically smooths out the peaks resulting from different picking speeds.

The PocketEngine has a standard design with three floors. Each of the three floors has a separate function implemented using proven technologies.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Looking for an all-in-one pocket solution?

Introducing PocketEngine – a revolutionary new pocket sorter

A pocket sorter system for every business case

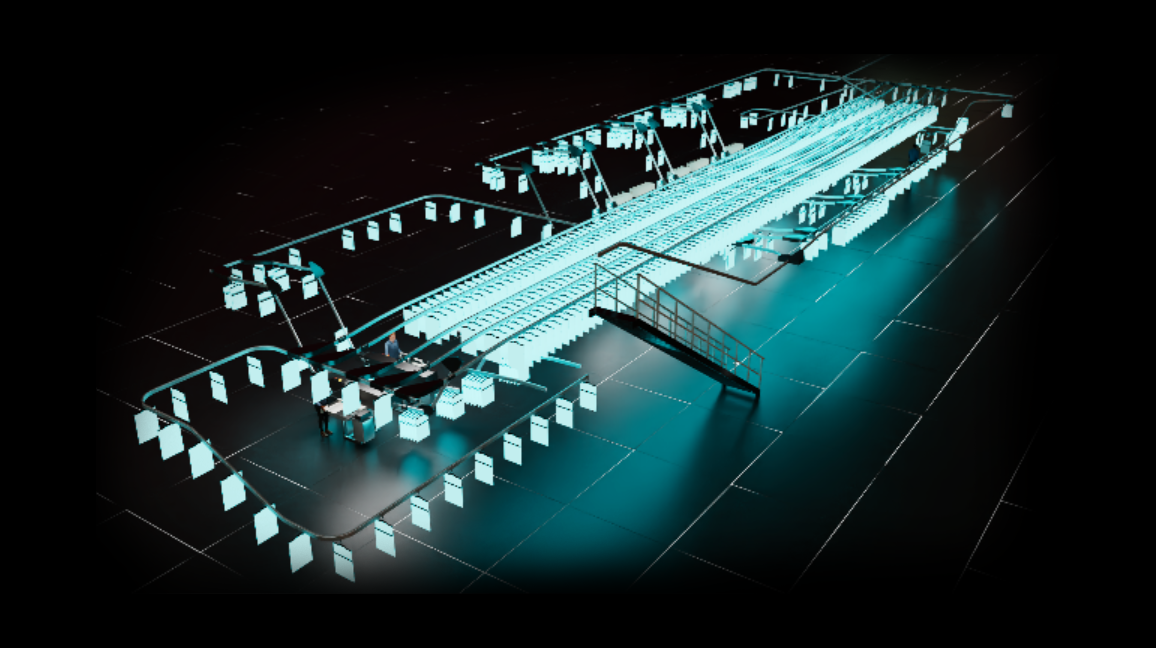

The PocketEngine has a standard layout, but is flexible enough to handle a number of applications. The pocket sorter system does it all, from induction, buffering and sequencing to retrieval, thereby covering the entire process and providing the ideal solution for many different business cases.

Perfect sequencing and buffering are essential for efficient fulfillment in e-commerce. PocketEngine exceeds both of these requirements and is able to process hanging garments as well as folded or flat-packed goods.

PocketEngine consolidates hanging, folded and flat-packed goods in a store-friendly manner and combines EcoFlow adapters with EcoPockets for highly efficient order processing.

Returns can be temporarily stored in the dynamic buffer to allow employees to retrieve these items quickly and efficiently all throughout order processing.

Perfect sequencing in three easy steps

PocketEngine collects goods from all areas of the warehouse and sorts them, creating perfect sequences for highly efficient order processing. But what exactly does this process look like?

Items flow into the PocketEngine from throughout the warehouse, coming from different storage systems and having been picked at different speeds. In the induction area, employees fill the pockets with items at ergonomic work stations. Furthermore, each item is linked to its pocket in the system. From induction, the pockets are conveyed to the consolidation buffer on the top floor.

The Run-Buffer and sequencing sorter are located on the middle floor. The sequencing sorter arranges the items in the correct sequence, preparing them for efficient packing.

Orders are assembled in the packing area, where the system automatically divides the workload between the available pack stations to compensate for different packing speeds.

One pocket, unlimited possibilities

At the heart of the entire PocketEngine is the proven EcoPocket, a pocket sorter system that sequences orders for both e-commerce and store delivery. The PocketEngine comprises the EcoPocket with additional induction and pack stations, consolidation buffers and Run-Buffers.

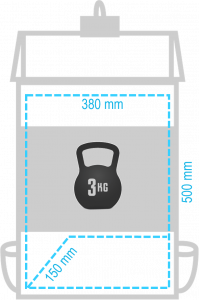

All pockets used in the PocketEngine are the same size. With dimensions of 500 x 380 x 150 mm (20 x 15 x 6 in), they can hold small and medium-sized items such as cosmetics, electronics, folded goods or accessories, and even larger goods weighing up to 3 kg (6.6 lb) such as shoes in boxes.

Limited warehouse space? Enough room for PocketEngine Lite!

The PocketEngine comes in two standard sizes: Full Size and Lite. Both systems function in the same way; they only differ in size and the number of pockets, induction and pack stations and buffers. This is how PocketEngine can offer the right solution for all your performance, space and budget requirements.

PocketEngine Full Size

PocketEngine Lite

Induct Stations

10

4

Run-Buffer

12

8

EcoPockets

17.500

9.500

Pack stations

20

7

Consolidation buffer

8-14*

4-8*

*depending on item size

Do you have questions regarding the PocketEngine pocket sorter system?

Want to read more about pocket sorters? Check out our blog posts:

Do you fancy a new outfit? Or a fashion accessory? From a wardrobe full of intelligent technologies and innovations, we put together the perfect logistics solutions from size S to XL, tailored to the demands and level of automation.

Data and information play a vital role in logistics. Real added value is generated along the entire value creation chain by intelligently integrating information and automated systems.

Dürkopp Fördertechnik has been part of the KNAPP group since 2010. Thanks to this merger, we’ve got a first class collaboration providing expertise and industry know-how from a single source. Johannes Holas and Sigurd Völker reminisce about the past 10 years.