Challenge your limits

Limits are meant to be overcome and, for warehousing and distribution, it’s a sure thing with our scalable automation solutions. Are you currently facing challenges in your intralogistics or anticipating the challenges to come? KNAPP delivers the answers with flexible, expandable systems.

We have been asking ourselves:

How can we best integrate the trends and market demands into new solutions?

We are finding the answers through partnership, innovation and all-in-one solutions. As a family-owned business, the individuality of our customers is particularly important to us, so solutions are customized. Here, transparency, system availability and flexible expansion each play an important role. With this in mind, our Wholesale Team focusses on the following business sectors:

- Spare parts and tools

- Electronics and electrical components

- Media (wholesalers of books, audio and video)

- Stationery and office supplies

- Optics, lifestyle and fashion

- Courier, express and parcel services (CEP services)

- Jewelry

Discover our logistics concepts for wholesale – contact us at sales@knapp.com.

In addition to developing new solutions, we also improve existing solutions. It’s our goal and aspiration to build up and continue developing long-term partnerships based on innovative system solutions.

Innovation

Change as a chance for new technologies

Over the past years, Würth Industrie Service GmbH & Co. KG and KNAPP have implemented many projects together. Not only has this resulted in successful collaboration but also in an innovative partnership, out of which new innovative solutions continue to come.

Equipped with our cutting-edge robot solutions, Würth is a reliable partner for their customers. The Pick-it-Easy Robot picks orders fully automatically. This offers important advantages to employees, as the robots handle the physically strenuous tasks, contribute to a pleasant work environment for people and allow quality and productivity to increase.

Würth also uses the all-in-one work station Pick-it-Easy Evo. A broad range of add-ons for quality assurance, such as photo documentation, support employees and keep them motivated.

The new work station experience, thanks to our Pick-it-Easy Evo, promotes the warehouse worker to the role of smart worker and turns the work done at a simple work station in storage and production into an experience. Space-saving design, efficient order processing, ideal ergonomics and usability together result in optimum quality assurance.

Our innovative partnership with Würth has already led to many intelligent automation solutions and we look forward to the challenges of the future.

KNAPP is a partner who we can talk to on equal terms. Together, we consider the demands facing us in our markets and use them to develop new concepts by adapting existing technologies and developing new ones.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWürth has confidence in our modern automation and robot solutions:

Partnership

Collaboration as the basis for successful solutions

Our shared sense of innovation formed the cornerstone in 2012 for the successful business relationship between Kramp and KNAPP which is marked by flexibility and creativity. As Europe’s largest specialist for spare parts and agricultural supplies, Kramp relies on our flexible and automatic warehouse system – not just at one location, but six locations throughout Europe. In keeping with the Kramp slogan, “It’s that easy”, Kramp’s success rests on a smooth-running logistics and storage solution as well as the best customer service.

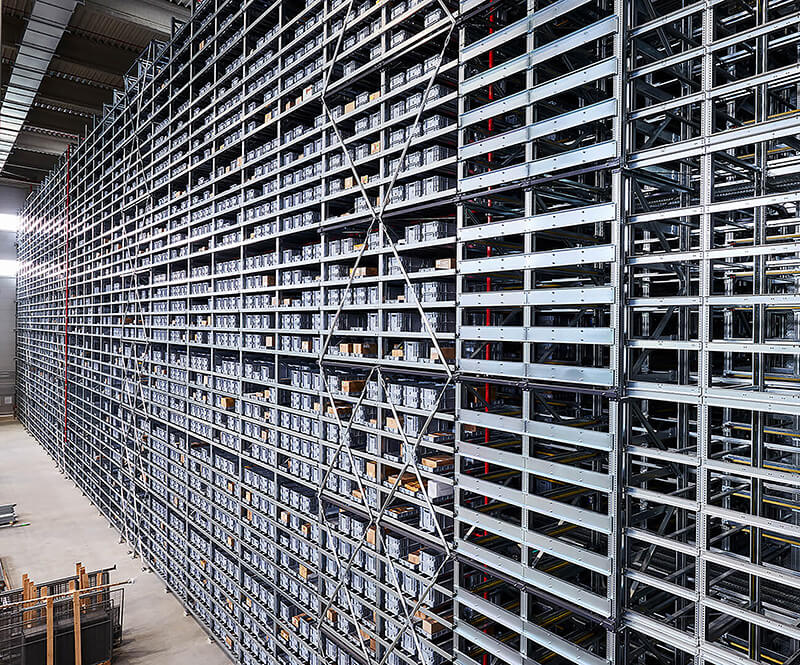

In 2018, the first ever OSR ShuttleTM Evo in the Netherlands was put into operation at Kramp. The customized, efficient logistics solution provided the innovation and change that would allow the company to always keep a step ahead.

The heart of this solution? The OSR Shuttle™ Evo. The system stores fast-, medium- and slow-moving items for replenishment, including bulky items. Controlling future growth and keeping up with continuously changing customer demands were the driving factors, therefore, the warehouse can be expanded step by step, with an ultimate performance of 9,600 order lines per hour.

Our intelligent software solution KiSoft finds just the right storage location for every item. Furthermore, employees in the Netherlands can enjoy their work at eight ergonomically designed Pick-it-Easy work stations. Thanks to the goods-to-person procedure, manual single item picking is particularly efficient.

Our solution provides straight-forward handling of the tremendous stock of more than 500,000 items, allowing Kramp to deliver to their customers, while keeping effort and cost to a minimum.

We’ve seen that customer requests are changing. Our customers want faster delivery, a greater selection and more spare parts – which means our shop keeps growing and we need more space. We also want to be flexible and deliver orders quickly. The OSR Shuttle™ Evo is a highly scalable solution which is exactly what we were looking for.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTradition

Future-proof systems as a measure of our work

As a family-run company, KNAPP concentrates on durable, future-proof solutions and by doing so, we drive innovation. We share this characteristic with our customers. Schukat electronic, for instance, a German specialist for electronic components and devices, relies on these values, resulting in a collaboration characterized by a focus on the future and on solutions. In November 2018, our automation solution began operation at Schukat electronics.

The linchpin of the solution is an OSR Shuttle™ Evo comprising 4 rack line systems including

levels

cross-running 2D shuttles

storage locations

Performance and number of storage locations can be independently scaled. The six goods-to-person work stations and the customized KiSoft-Software that interfaces with SAP®EWM round out the innovative logistics solution.

The system can be expanded to

rack line systems

storage locations

The OSR Shuttle™ Evo enables Schukat electronic to offer customized service to their customers. The flexibility of our solution has a direct bearing on the end customer.

As a pioneer in shuttle technology, KNAPP has more than 15 years of experience gained from more than 250 implemented shuttle systems. The new generation of OSR Shuttle™ Evo is the evolutionary development of proven shuttle technologies. We address the current trends in the industry, such as business developments that are difficult to plan for or rising demands for quality and performance.

I’m proud that I still enjoy striking out in new directions. This is why working with KNAPP was so interesting for us. KNAPP recognized that their customers have ideas and needs; they are willing to actively work on these tasks and to forge new paths.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe OSR Shuttle™ Evo is made up of modular building blocks comprising: