Shuttle Storage System for Efficient Order Fulfillment

The Evo Shuttle is an automated storage and retrieval system for containers, cartons and trays holding up to 50 kg (110 lb). Our shuttle storage system is the right choice for logistics applications demanding the highest performance in order fulfillment as well as maximum flexibility in processes.

It’s an ideal solution that comes with a broad range of applications including high performance e-commerce and online retail fulfillment, flexible processes in a manufacturing setting, or special applications such as those in the healthcare or food retail sectors.

Evo Shuttle: The core of performance

Processing myriads of orders every day? Do your customers demand the highest delivery quality and love your company because they get perfect service?

Be sure to lay the right foundation in your warehouse. Our automated shuttle storage system, Evo Shuttle, is the true core of performance in order fulfillment. The Evo Shuttle can provide you with the performance you need to thrill your customers and stay on top. With Evo Shuttle, you profit from maximum flexibility and efficiency in order processing. This makes our shuttle system the ideal element in an automated logistics solution where high performance is needed, such as in e‑commerce, micro fulfillment and omnichannel distribution.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAre you searching for the quintessential element, the core of performance?

Allow us to introduce the Evo Shuttle.

Automated storage and retrieval system (ASRS) for maximum flexibility and storage density

Are you racking your brains in goods-in to figure out where to store your goods? Forget about ABC analyses. In the Evo Shuttle automated storage and retrieval system, all goods are stored equally because stock and overstock are stored in one system. Store your inventory centrally and conveniently in a shuttle storage system and benefit from maximum flexibility and optimum storage density:

- Multiple-deep storage

- Load capacity up to 50 kg (110 lb)

- Containers, cartons, trays

- Various sizes: 250 x 250 mm – 850 x 650 mm (10 x 10 in – 33 x 26 in)

- Direct storage of cartons

- Different types of load carrier possible

With highest quality for your safety.

Evo Shuttle meets all FM Global Compliance requirements.

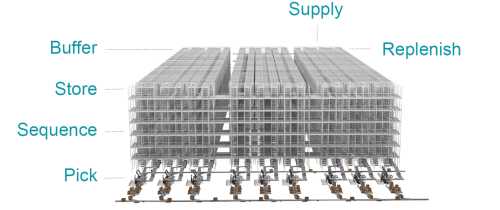

Store, buffer, sequence, replenish and

pick with the help of a single shuttle system

The Evo Shuttle 2D streamlines the logistics processes in the warehouse thanks to its ability to create precise sequences and to store stock and overstock centrally, two key features of the system and covering the following processes:

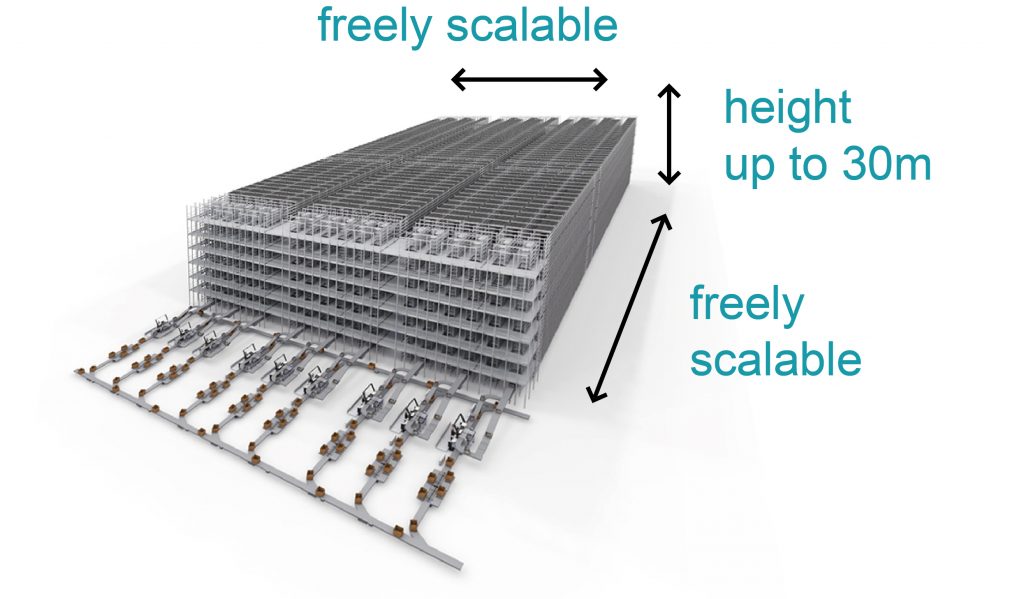

Optimized high-speed lift for systems over 30 m (98 ft)

Evo Shuttle is setting new dimensions not only for throughput, but also for system height. The new lift system can be built to a maximum height of over 30 meters, or approximately 98 feet, which provides a better use of floorspace and optimized storage capacities. The maximum speed of the lift system is now even faster, which increases the throughput of the overall system. With more than 1,000 double cycles per hour at each rack line, the lift system is elemental to the system’s overall high performance.

Evo Shuttle – as you like it

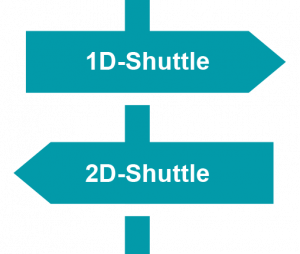

We have the right shuttle system to meet all your requirements. If you need a real powerhouse, Evo Shuttle 1D is the right choice with one shuttle per level. However, if you’re looking for more flexibility in the design of your processes, Evo Shuttle 2D is your go-to system, as these shuttles can move between the rack line systems and reach all the lifts on the level. With this approach, performance and the number of storage locations can be scaled independent of one another. In addition, our system allows items to be retrieved from the rack line system in the exact sequence required. The special system design makes efficient one-touch fulfillment a reality, with every work station being able to access every item.

Evo Shuttle 1D: High-performance ASRS for your warehouse processes

The Evo Shuttle 1D is designed to fulfill high performance requirements, as needed in online retail or the pharma sector. One shuttle runs per level and aisle, handling the storage and retrieval movements for the storage locations in that area. This approach keeps fulfillment times at their fastest and maximizes throughput in the warehouse. A high-performance pre-zone loop supplies items from storage to the connected work stations. The Evo Shuttle 1D is ideal for warehouses with a high throughput and a high inventory turnover rate.

Full performance at -28 °C (-18 °F)

When storing frozen goods, special system features are needed. Automated processes help to reduce the workload for employees at low temperatures and the short throughput times help to ensure the freshness and quality of the goods.

In a freezer warehouse, some components must be adapted to the low temperatures. Cold-resistant lubricant, for example, helps to ensure that the Evo Shuttle system can work reliably even at temperatures as low as -28 degrees Celsius, or -18 °F). The Evo Shuttle system is already being used in icy temperatures by our customer Shufersal, where it is delivering fast and straightforward order fulfillment.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationEssilorLuxottica: Central distribution platform

for shipping designer glasses worldwide

EssilorLuxottica is a leading designer, manufacturer and retailer of exclusive luxury and sports eyewear and fashion. Their global business model includes supplying retailers and wholesalers and connecting them to production facilities. To meet the complex requirements of their different business models in one fully integrated logistics solution, EssilorLuxottica built an omnichannel warehouse in Sedico, Italy.

The heart of the solution is the powerful Evo Shuttle, whose 450 individual shuttles tirelessly retrieve containers from the system’s 500,000 storage locations and bring them to the downstream Pick-it-Easy work stations. EssilorLuxottica opted for the high-performance Evo Shuttle 1D variant to handle the 33,000 packages leaving their warehouse each day, which corresponds to a performance of 205,000 items per 7.5-hour shift.

Evo Shuttle 2D: Maximum flexibility

When it comes to extra flexible warehouse processes, the Evo Shuttle 2D is the best bet. Items come straight from the storage in perfect sequence, requiring no additional pre-zone. The shuttles in the system can switch aisles, allowing them to reach each lift in the system. Furthermore, the system can be expanded flexibly since the number of storage locations can be scaled separately from performance. Need higher throughput? Add more shuttles. Need more storage capacity? Add more rack lines. Without the pre-zone, this system design also has a trimmer footprint.

Get the most out of the space you have with Evo Shuttle 2D

Make the best of your available space when designing your system. The shuttle storage system is scalable in length and width and can reach heights of over 30 meters (98 ft). What’s more, the Evo Shuttle can be expanded simply by adding more shuttles or rack line systems, allowing your warehouse to grow along with your business.

Arvato: Omnichannel fulfillment for premium beauty products

As one of the leading third-party logistics providers (3PLs), Arvato uses innovative technologies to develop bespoke solutions for their B2B and B2C customers. This is exactly how we developed an automation solution for the DOUGLAS Group in Hamm, Germany, in a project focused on consolidating six warehouses into one central one that would fulfill orders for all distribution channels, supporting the DOUGLAS Group’s omnichannel strategy and facilitating continued growth.

The central feature of this omnichannel solution is the Evo Shuttle 2D. Worldwide, it’s the largest 2D shuttle solution in the cosmetics sector and offers top flexibility while making the most of the available space, storing and retrieving 12,500 containers per hour. Upon retrieval from double-deep storage, containers are transported onward for further picking. The system allows Arvato to handle significant differences in order structures and flatten peaks, making it ideal for the stringent requirements of omnichannel fulfillment in the beauty and lifestyle sector.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBenefits of the Evo Shuttle storage system

30 meter rack height (98 ft)

Optimal use of space, multiple-deep storage, optimal storage density

Endless possibilities

Store containers, cartons and trays of various sizes

Gentle handling

Low vibrations in rack make it ideal for sensitive and expensive goods

Complete sequencing

Straight from the racks for efficient processes

Always on top of things

Integrated software keeps track of the entire stock

6 in 1

Store and retrieve, buffer and sequence, replenish and pick – all your processes in one system

Safety first

Earthquake-resistant design, fulfills FM global regulations, highest safety for personnel

-28 to +40 °Celsius (-18 to 104 °F)

Use in various temperature zones

Spare parts and 24/7 Service Desk

Rapid provision of spare parts; robust, low-maintenance system; access to experts 24/7

Add-ons to complete your shuttle solution

Added value and success only arise from the intelligent combination of technologies and processes. The Shuttle Evo forms a particularly strong team with the following products:

Goods-to-person work stations

Efficient picking is what you get with our Pick-it-Easy series. Our work stations combine quality assurance, ergonomic working and a user-friendly design for the employee. We offer various designs for different processes and applications.

Goods-to-Robot

Picking

The Pick-it-Easy Robot provides precise, fully automatic order processing, especially where personnel are in short supply. The robot uses its artificial intelligence to ideally process a wide range of goods.

Pocket system solutions

Hanging and flat-packed goods, whether shirts, shoes or accessories, can all be transported and buffered together in one system. The pocket sorter systems suit e¬commerce and omnichannel fulfillment particularly well.

Autonomous mobile robots (AMRs)

Our Open Shuttles create a flexible connection between the Evo Shuttle and various other storage and process areas, making extra conveyors redundant.

Logistics software

KiSoft controls the storage and retrieval of containers, trays and cartons as well as the shuttles. The software handles order management and keeps track of stock.

Lay the right foundation for your warehouse today.

Exciting blog posts about

Warehouse and value chain automation

The requirements for freezer warehouses are complex. A high degree of automation is an important ingredient for success. Find out more about the challenges of operating a freezer warehouse, what makes it special and different logistical approaches.

The OSR Shuttle continues to go the distance, setting new benchmarks in shuttle technology. But what are the hidden benefits behind this successful concept? Hit play on shuffle mode to enjoy this playlist of shuttle benefits!

In logistics, sustainability is an omnipresent topic. We would like to show you 4 good reasons why it makes sense to protect the environment, work efficiently and benefit from the many positive effects. Find out more!