Automatic conveying, sorting, and handling

Intelligent sorters, conveyor systems, and handling systems for goods play a key role in logistics processes. They network warehouse areas with one another and ensure that goods as well as transport and storage containers are always in the right place in the goods flow at the right time.

We have an extensive portfolio of conveyor systems for single items, containers, and cartons, as well as for pallets. We also offer autonomous mobile robots for flexible transport tasks and overhead conveyor systems. Rapid dispatch sorters, dispatch buffers, pocket sorters, and flat-packed goods sorters are also staples in our portfolio. We also have a wide selection to choose from for efficient, automated handling of containers and cartons.

Pocket Sorter

EcoPocket: The pocket sorter system for e-commerce and omnichannel

Flexible pocket systems are indispensable, especially in e-commerce and omnichannel fulfillment. Hanging goods and flat-packed goods – such as shirts, shoes or accessories – can all be transported and buffered together in one system. The EcoPocket is therefore ideal for applications in the e-commerce and omnichannel areas, which need high performance and a great deal of sorting. The pocket sorter system is equipped with RFID technology, so 100 % tracking, accurate identification and access at any time to any item in the system are all in the bag. Intelligent matrix sortation brings order to otherwise chaotically buffered goods and provides a reliable 100 % sequence, sorted according to the desired criteria.

Would you like to know more?

3 great reasons to choose EcoPocket

Together with Dürkopp Fördertechnik, we have more than 10 years of experience in pocket sorter solutions. Worldwide, more than 50 systems are running with more than 5 million sorter pockets. Our customers appreciate the value EcoPocket offers through its quality, efficiency and flexibility.

EcoPocket: An athletic pocket sorter system for DECATHLON

Decathlon was planning the expansion of their e-commerce business. They wanted to find a compact system with a high throughput that could be integrated into their existing building. Their vast product range covers more than 70 kinds of sport. Smaller items such as backpacks or even camping items packed in cartons are conveniently stored and organized in the sorter pocket. The globally acting French manufacturer of sports equipment and clothing fulfills online shop orders and ships to stores from their logistics center in Schwetzingen, Germany.

Find out more about our solution at Decathlon here.

During seasonal peaks, distribution centers are doing a tremendous amount of sorting. Our intelligent Pocket Sorter is the perfect solution for this demanding task, as it has been designed to deliver maximum performance and accuracy. Flat and hanging products – such as shirts, shoes or accessories, irrespective of whether they are delivered by a supplier or as a return – can all be transported and dynamically buffered in one and the same system.

Intelligently integrated: A sorter pocket for every situation

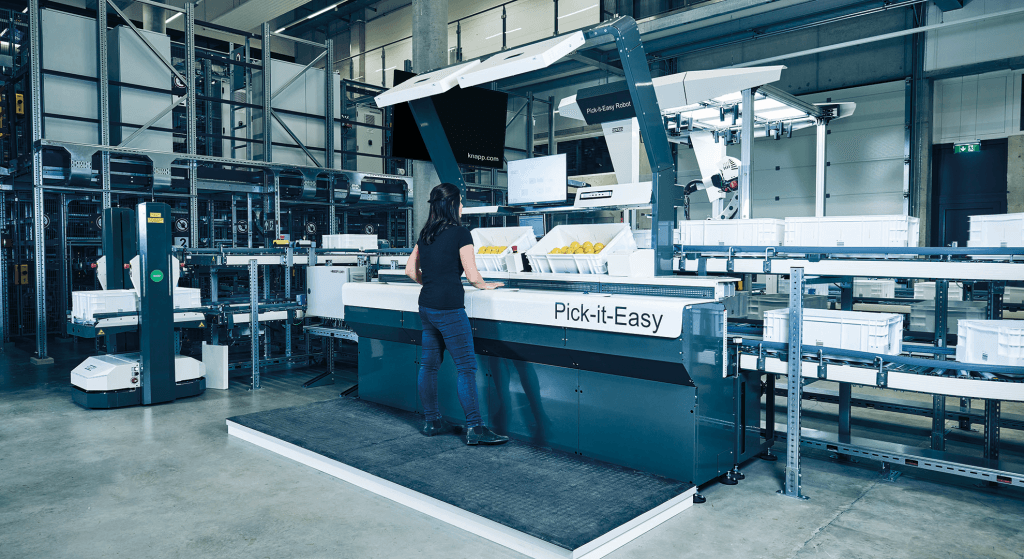

EcoPocket + Pick-it-Easy work station

Poetry in motion. A central hub in the sortation system ensures maximum performance and flexibility in the modern omnichannel warehouse. It connects the Pick-it-Easy work stations to the sorter pockets in every sorter module. As a result, you can process any customer order from any work station.

EcoPocket + Pick-it-Easy Robot

Robot fashionista. Combining the powerful pocket sorter system and the Pick-it-Easy Robot results in an efficient no-touch solution for omnichannel applications, especially in the fashion and retail sectors.

AutoPocket: New momentum for pocket sorters

Are you investing a lot of time and effort in sorting your goods? Struggling to find a solution that meets your performance requirements and includes efficient returns handling? Then AutoPocket is just the right solution for you! In the light of greater demands for fast delivery times, insufficient space in urban areas and personnel shortages, this intelligent pocket sorter system is specially designed for industries handling a wide range of goods, offering many opportunities for optimizing logistics processes.

Innovative design meets intelligent software

The intelligent software and control technology behind our AutoPocket provides vital information and adds value. The software works like a sophisticated traffic concept calculating the ideal flow of vehicles in big cities – it optimizes the flow of goods and prevents accumulations and chaos.

The perfect sequence with AutoPocket

AutoPocket can automatically and precisely drop off goods anywhere in the warehouse, without slowing down or stopping. Equipped with RFID technology, the solution is able to access and track all items seamlessly at any time, as well as clearly identify them.

Three great reasons to choose AutoPocket

AutoPocket condenses our decades of experience into a whole new approach. The system helps fulfill orders efficiently, opens up new opportunities and boosts logistical processes.

- Zero touch fulfillment

- Automatic goods drop off at full speed at any location in the warehouse

- Ideal for omnichannel and e commerce

- Wide array of items

- Simple returns handling

- Innovative product design meets intelligent software

- Scalable and space-saving system design

- Scales up flexibly for growth

AutoPocket at NEXT PLC

NEXT PLC is a leading retailer of women’s, men’s and children’s fashion as well as of modern furniture and decor. Their products are available in over 500 stores across the UK and Ireland, with their online presence growing tremendously. On the international stage, the NEXT group offers their products in around 200 brick and mortar stores, as well as an online store for customers abroad.

To accommodate their needs in online retail, NEXT commissioned KNAPP to automate their new e-commerce warehouse in 2021. The warehouse will feature AutoPocket, our intelligent pocket sorter system, in combination with shuttle technology and goods-to-person picking. The solution was specifically designed to simplify the complex requirements in warehouses and to reduce the time needed for processing customer orders. The two AutoPocket modules handle 15,000 items per hour and will help NEXT sort 5,000 packages per hour in the goods-out area.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationIntelligently integrated – the pocket for every situation

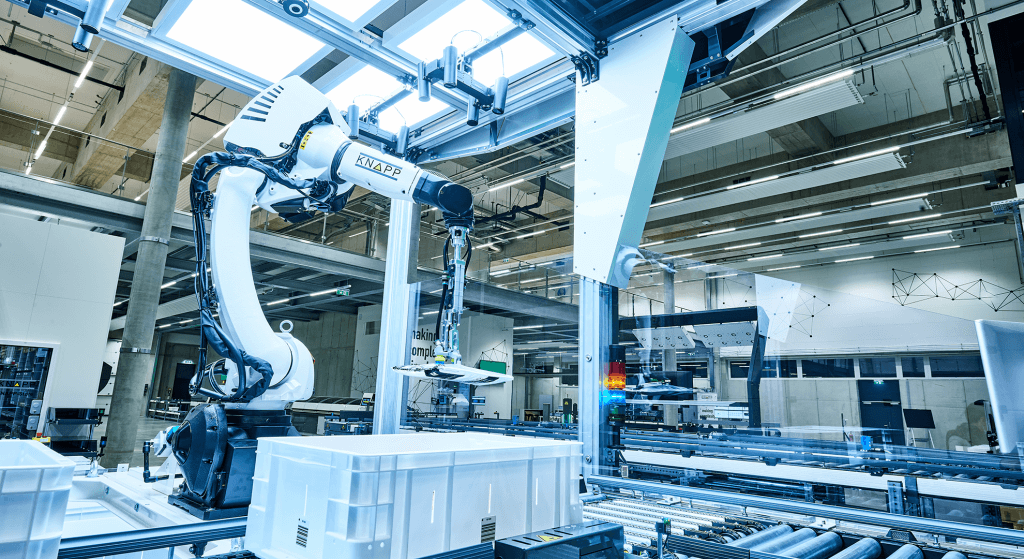

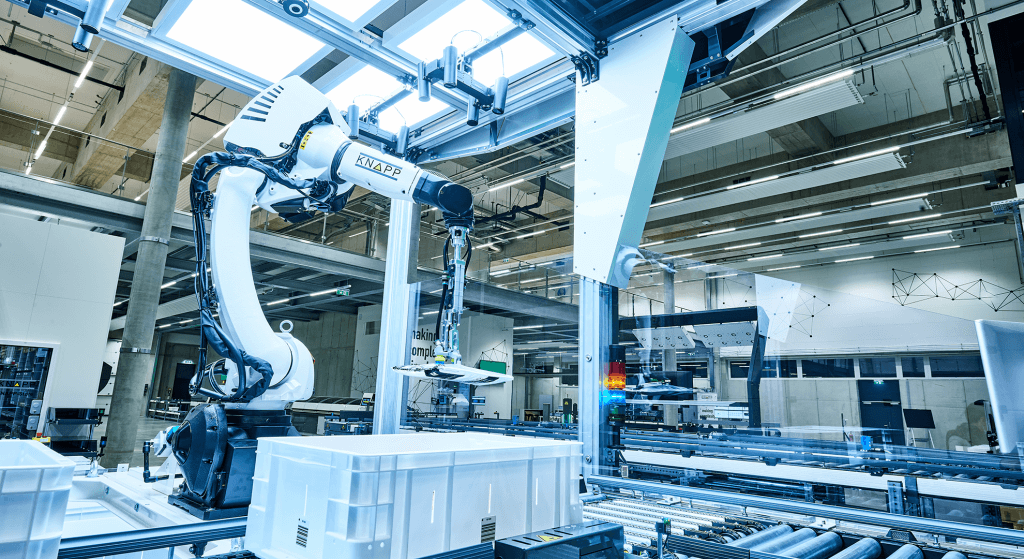

AutoPocket + Pick-it-Easy Robot

AutoPocket, combined with Pick-it-Easy Robot, our fully-automatic picking robot, offers intelligent zero-touch handling for high-performance operations.

Discover more about our intelligent pocket sorter solutions in our blog post and at Dürkopp Fördertechnik.

Sorting systems

A high-performance sorting system: Split Tray Sorter

The split tray sorter is a high-performance sorting system that reliably and quickly sorts flat-packed goods. The split tray sorter is above all suited for use in the fashion and textile sectors. The solution consists of belt tray elements, on which the right items are placed. The items are recognized based on their barcodes. At the target location, the tray opens, causing the single item to fall into a container or carton, or onto a chute.

Learn more about our split tray sorter systems.

Sequencing, sorting and buffering orders: OSR Shuttle™ Sorter

The OSR Shuttle™ Sorter is designed for use in order fulfillment and distribution centers, especially in high-performance operations. It allows resources to be used effectively and more flexibly and evens out the peak and slack periods. The OSR Shuttle™ Sorter is ideally suited for omnichannel and multichannel applications as well as for the following tasks:

- Supplying flow racks automatically and at the right time

- Buffering, sequencing and sorting goods ready for shipping

- Decoupling picking processes from shipping processes

- Cross-docking

The flexible, scalable design of the OSR Shuttle™ Sorter is adapted to individual warehouse demands and can be easily expanded when needed.

Conveyors and transport systems

Open Shuttles: flexible and simple transport processes

Our autonomous mobile robots, the Open Shuttles, make the design of flexible transport processes as easy as ABC. They connect different areas within facilities quickly and efficiently, bringing goods, raw materials and components to where they need to be. Since our Open Shuttles move around independently, they do not rely on aids for navigation. Thanks to integrated sensors and scanners, they constantly scan their environment, making them absolutely safe for humans. What’s more, our Open Shuttles are compatible with the VDA-5050 interface and can be easily integrated into existing systems.

Get more insights into our autonomous mobile robots Open Shuttles.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe modern conveyor system for containers and cartons: Streamline

Streamline, our universal conveyor system, is specially designed for flexible use in picking and distribution centers. As the heart and soul of intralogistics systems, it supplies many different areas in a warehouse with the right goods efficiently and reliably. Streamline conveys containers, trays, cartons and soft packaging with a weight of up to 50 kg (110 lb.)

The conveyor system is made up of modular building blocks. With one or multiple components available for every logistical task, the uninterrupted supply of different installations and machines is ensured. Thanks to the smart integration into our software, the right information is available at the right time.

Want to know more?

Three great reasons to opt for Streamline

Streamline was developed with efficiency, process reliability and smart software integration in mind to guarantee a standardized, end-to-end conceptual design.

• Components designed to meet specific requirements

• Fast installation and startup thanks to the modular system and high degree of pre-assembly

• Intuitive full visualization

• Reduced maintenance times thanks to simple replacement of entire assemblies

• Simple interface between different systems and products

• Easy modification and expansion possibilities

Streamline for intelligent automation at Wehkamp

Dutch online retailer wehkamp.nl boasts an e-commerce logistics center of the size of around 110,000 square meters (approx. 1,184,000 ft2). This huge space houses a modern logistics solution: Here, highly automated processes and manual processes mesh harmoniously with each other to provide optimal performance, elegantly implementing classic warehouse processes such as goods-in, storage, picking, packing, dispatch and returns handling.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationIf you look at the solution as a whole, it’s a complete solution that interconnects all processes, making us extremely reliable and enabling us to serve our customers the way we promised. It’s a highly reliable, state-of-the-art fulfillment center

Streamline – Intelligently integrated

Streamline + OSR Shuttle™

A powerful duo. Streamline and the automatic OSR Shuttle™ storage system are the perfect match when it comes to intelligent and scalable logistics solutions. Supplying the entire intralogistics efficiently and reliably, they meet the requirements of modern distribution centers.

Streamline + KiSoft SCADA

Eagle eyed. Integrated Streamline into our KiSoft SCADA software creates the perfect tool for system monitoring. Thanks to intuitive full visualization of every system area, the operational state and status of each area is visible at a glance.

The new generation of pallet conveyor system: Powerline

The conveyor system is the main artery of an intralogistics system and therefore the foundation for efficient processes – our Powerline pallet conveyor system is all about maximum efficiency, the greatest possible availability, and high profitability. The basic concept for Powerline leans heavily on the proven principles and innovations of the container conveyor system, Streamline. Years of experience and new concepts thus converge to form a modern product, harmoniously suited to a modern warehouse.

Want to know more?

Three great reasons to opt for Powerline

Powerline fulfills all logistics functions from conveying, transferring, and diverting, to zero pressure accumulation.

• Shorter implementation time, quick startup and availability possible

• Easier spare parts management and maintenance thanks to end-to-end parts commonality

• Work stations or transfer units can be integrated into the buffer conveyor without needing another drive unit

• Maximum energy efficiency thanks to state-of-the-art design and integrated EcoMode

• Errors are quickly and efficiently located thanks to the intelligent structure

• easyUse operating concept creates modern human-machine communication

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationHandling, stacking and separating

Powerful, economical and efficient: Automated handling systems

Handling load carriers and documents manually is not only inefficient with regard to time and resources, it’s also boring and invites errors. Our handling systems can reliably and efficiently automate these processes to optimize order handling.

• Stacking

• Destacking

• Emptying

• Closing

• Erecting

• Closing

• Placing inner cartons

• Opening

• Strapping

• Depalletizing various handling units and loading them directly into storage containers

• Palletizing store containers or empty handling units layer by layer

• Stacking and destacking cartons and standard handling units

• Loading various container types onto dollies

• Mixed case palletizing of cartons or store containers

• Optimized serviceability because the components are easily accessible

• Incredible cost-effectiveness and time-savings with features such as “just-in-time” print data

• Quiet operation and on-demand energy consumption

• Uniform and easy user guidance with visualization

Packing and Transport

Our comprehensive portfolio of automatic and semi-automatic systems for packing and securing goods for transport ensures both the highest quality and security:

- Bagging machine

- Pallet wrapper

- Banding machine

- Strapping machine

- Shrink wrapper

More on automatic conveying, sorting, and handling

Quite often, shuttle storage systems are the heart of our customers’ logistics systems. But when the product life cycle is coming to an end, what are the options? We show you how a step-by-step retrofit plan works.

Logistics and sustainability – a contradiction?

Read on to find out why sustainability in logistics is becoming more and more important, which advantages and challenges result from sustainable logistics and how technology and automation can help make it a reality.