Automatically record master data and digitize processes

Master data builds the foundation of automation and is essential for state-of-the-art, pioneering logistics processes. To keep processes running smoothly, master data does not only need to be recorded, but needs to remain up to date and available. Two leading, all-in-one measuring devices are available to ensure this: MultiScan, the solution for automated master data recording during goods-in and goods-out, and ProfileScan, a solution for automated master data recording during ongoing operation. Both devices capture relevant product information and attributes in a matter of seconds and then transfer the data to WMS or ERP systems using standard interfaces.

The self-learning software solution KiSoft Genomix automatically decodes the DNA of items, which is made possible by collecting and maintaining all item attributes that are relevant in an automated warehouse environment. Innovative automated technologies such as Vision Blister and Vision Item Check perform reliable, highly efficient and resource-sparing quality checks.

MultiScan – The all-in-one solution for recording master data

Correct master data is a basic requirement for automating goods flows. MultiScan automatically records all master data and product attributes that are relevant for logistics and transmits them to the higher-level WMS or ERP system using standard interfaces. Master data relevant for logistics includes dimensions, product weight, fragility, stackability, packaging hierarchies and material information. The intuitive, easy-to-use WebApp software supports master data recording and can be adapted to a particular customer quickly and easily. MultiScan means automated master data recording succeeds from the start. The all-in-one solution supports the digitalization of work processes and other processes, increasing competitiveness.

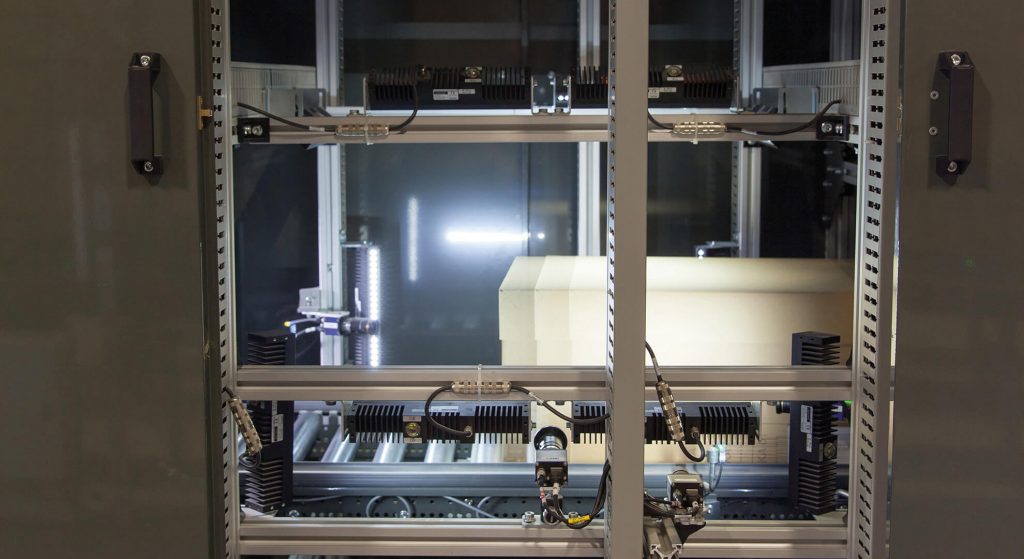

ProfileScan – Item master data directly in the goods flow

Correct item dimensions and product data are needed at different stages of the automated goods flow. ProfileScan supports the process by checking the product profiles and the product dimensions at speeds of up to 2 m/s (6.56 ft/s). The measuring frame with an infrared light curtain is integrated directly into the material flow, such as over a roller or belt conveyor. Thanks to its modular construction, it can also be integrated into a closed conveyor system, which significantly reduces time and effort when installing ProfileScan. Different standard interfaces are available to provide a connection to the higher-level control system.

Would you like to learn more about automatically recording item master data in goods flows?

3 great reasons to choose ProfileScan

ProfileScan is the perfect all-in-one solution for automatically measuring products and packaging directly in the goods flow and then using the measurement data to control material flows and evaluate the quality of transport goods.

Smart

- Fully automatic recording of product dimensions

- Modular construction for easy installation in installations with closed conveyor systems

- Standardized transfer of recorded master data and characteristics

Flexible

- Available in different widths and heights

- Precise measurement at conveyor speeds of up to 2 m/s (6.56 ft/s)

- Range of interfaces allow for easy integration

Robust

- Precise, automated recording of item dimensions

- Controlled process for ensuring quality requirements are met

- Low maintenance and reliable during long-term operation

Vision Blister: the reliable checker of tablet blister packs

Vision Blister is a solution developed for the pharmaceutical supply chain that has proven to be incredibly effective in mail order and central fill (MOCF) systems. The system carefully checks tablets in special blister packs. To meet quality criteria and protect patient safety, Vision Blister records and checks the:

- color

- shape

- quantity

- and imprints

of the tablets. As a result, Vision Blister ensures that resources are used efficiently. Time-consuming manual checks carried out by specially trained employees are a thing of the past.

Efficiency and quality for single-time checks: Vision Item Check

Fulfilling high demands for quality requires time and is usually achieved at the cost of throughput. With Vision Item Check, we offer the right solution for increasing efficiency in the check processes while still fulfilling the highest requirements for quality. Using a camera system for 6-sided reading, Vision Item Check automatically captures and processes security features on packaging, lot information, date marks or other quality features of the item from 1D and 2D codes. The system is suitable for incoming and returned goods, for use at special check stations, and for retrofitting.

- Patented V-belt conveyor

- Powerful camera system for 6-sided reading to capture information from 1D and 2D codes

- KiSoft Vision: specialized image recognition and processing software

- Touch screens with easyUse interfaces for simple operation and modern human-machine communication

- Modern work station design with KiDesign ergonomics

All this ensures that orders are automatically checked for completeness and correctness – no time-consuming manual checks required.

For Optimum Quality and Performance: Checks and Measurement Systems

Vision Scan-Tunnel

Vision technology is one of the keys to our zero defect warehouse concept. The Vision Scan Tunnel is a reliable solution for handling and checking containers and cartons. It’s suitable for smart automation in goods-in, because goods-in is where process reliability begins. The Vision Scan Tunnel captures information contained in 1D and 2D codes on cartons or containers using its high-performance camera system. Optionally, characteristics such as straps, safety or adhesive tape, and dirt can also be detected: Using the Vision Scan Tunnel can also simplify downstream processes considerably.

KiSoft Genomix – decoding item DNA

KiSoft Genomix automatically decodes the DNA of items. Our new self-learning all-in-one package maintains all attributes of items that are relevant in an automated warehouse environment. It perfectly adjusts to the degree of automation of the installation in the warehouse. The system centrally provides all the parameters that the automated technology needs for optimal handling. In doing so, KiSoft Genomix increases efficiency and performance.

More on quality assurance and master data

What does the smart factory of the future look like? Find out more about our vision for smart manufacturing!