Blister Packing Machine for Packing Patient Blister Cards

When faced with current developments, such as the shortage of healthcare workers and worldwide demographic change, carers and pharmacists now have a powerful ally: automated blister packing machines for creating patient-specific blister cards. They’re an efficient way of ensuring safe medication management for each and every patient while creating additional benefits for them along the way.

Fully automatic blister packing machines mean more efficiency and a higher quality of life

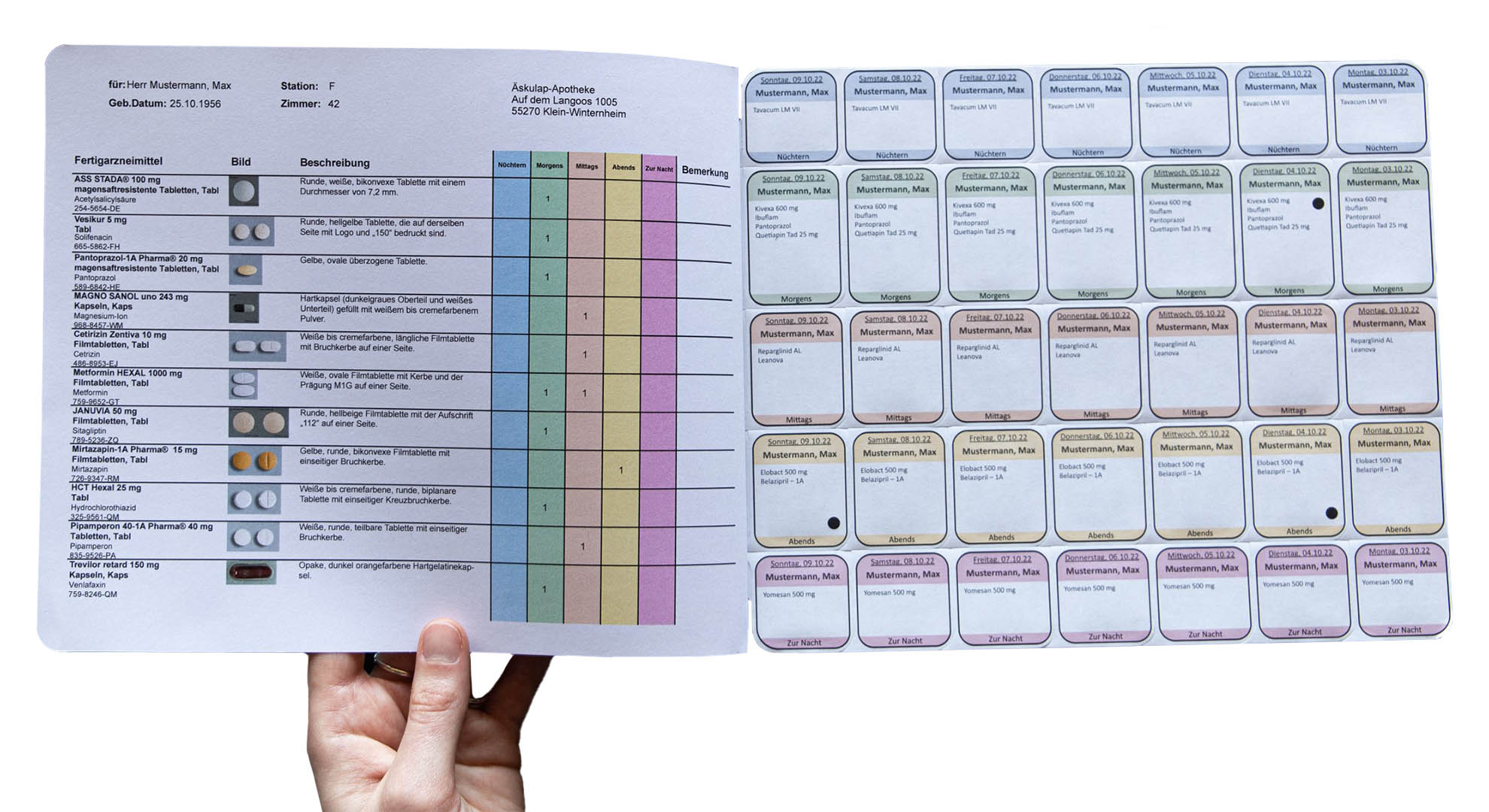

The shortage of healthcare workers is affecting the entire world. This, in combination with demographic changes in the world’s population, is placing unprecedented demands on the healthcare sector. However, patient-specific blister packing has risen to the challenge of ensuring that patient medication management remains safe and reliable. Prescription medicines are packed individually by day of the week and time of administration.

Pre-filled medication packs positively influence the effectiveness of prescribed treatment, thereby improving quality of life. The easy-to-take medicine in blister packs, along with reminders, increase medication adherence by up to 50 percent within a year. These changes also make a big difference for the environment.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information25 %

of the population regularly take 3 to 4 tablets per day

77 %

of all prescriptions are maintenance medications

50 %

increase in adherence thanks to easy-to-take medicine in blister packs

Looking for a fully automatic solution for patient-specific blister packaging?

Allow us to introduce the D³ Daily Dose Dispenser

Out of the blister, into the blister: The fully automatic D3 Daily Dose Dispenser

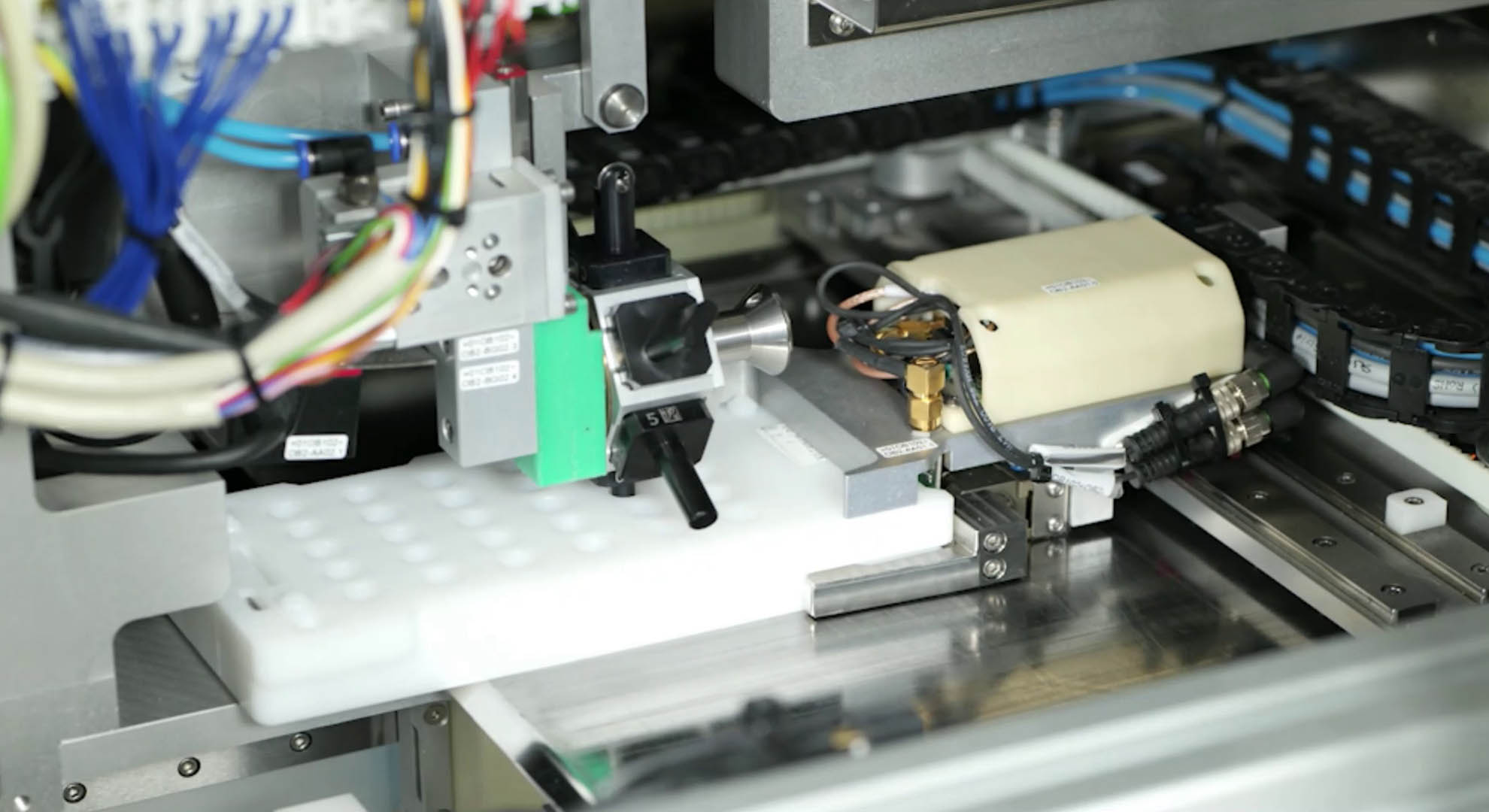

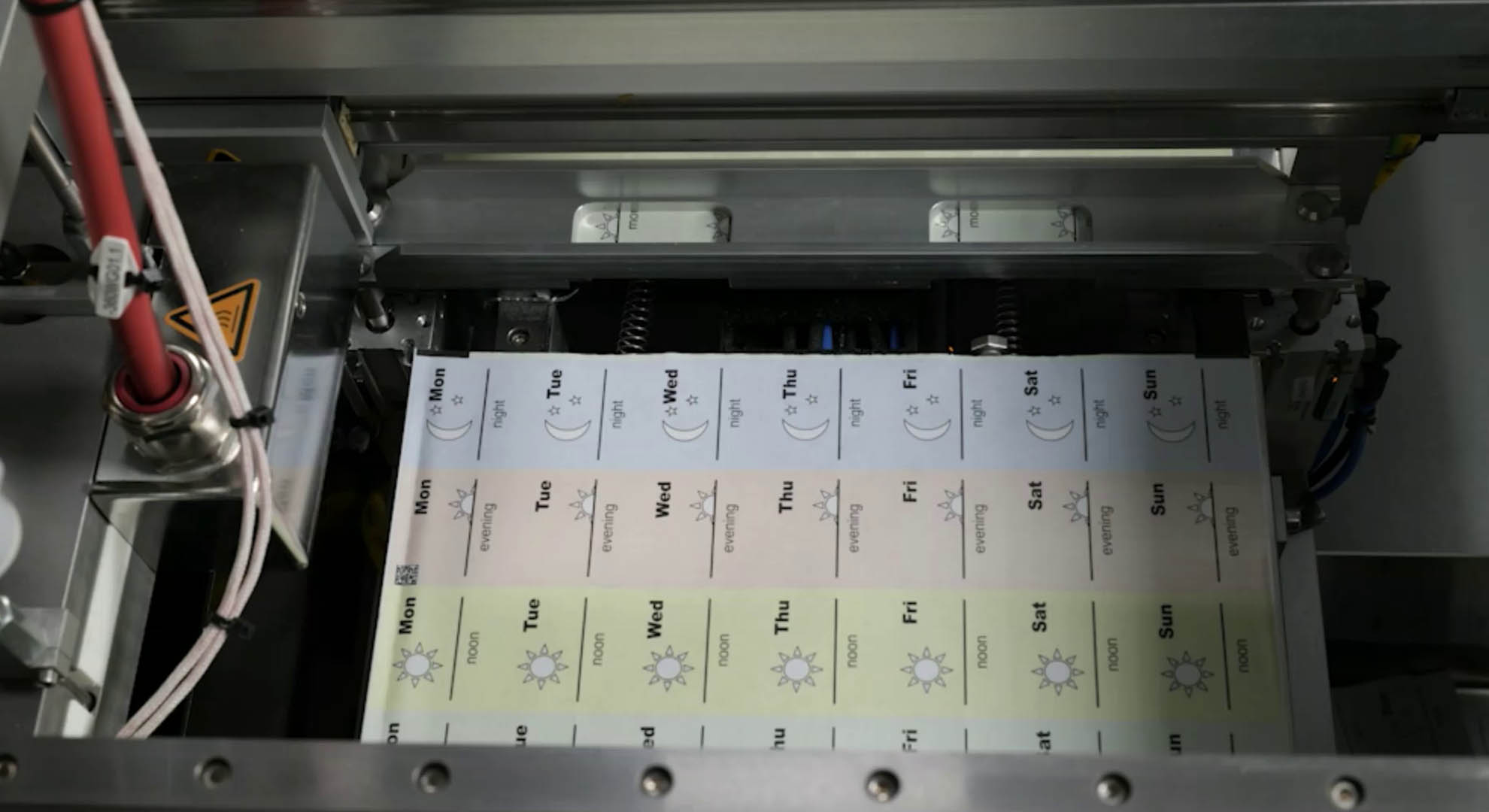

The D³ Daily Dose Dispenser blister packing machine provides support for the medication picking and repackaging processes, making life easier for producers of patient-specific blister packs. The process is fully automatic. Tablets are picked directly from the original blister pack into the new patient blister card and the card is then sealed and printed. The entire process supports pharmacy and healthcare workers, helping mitigate the effects of the labor shortage.

Advantages of automated blistering

The D3 blister packing machine offers plenty of advantages for manufacturers, patients and pharmacies alike:

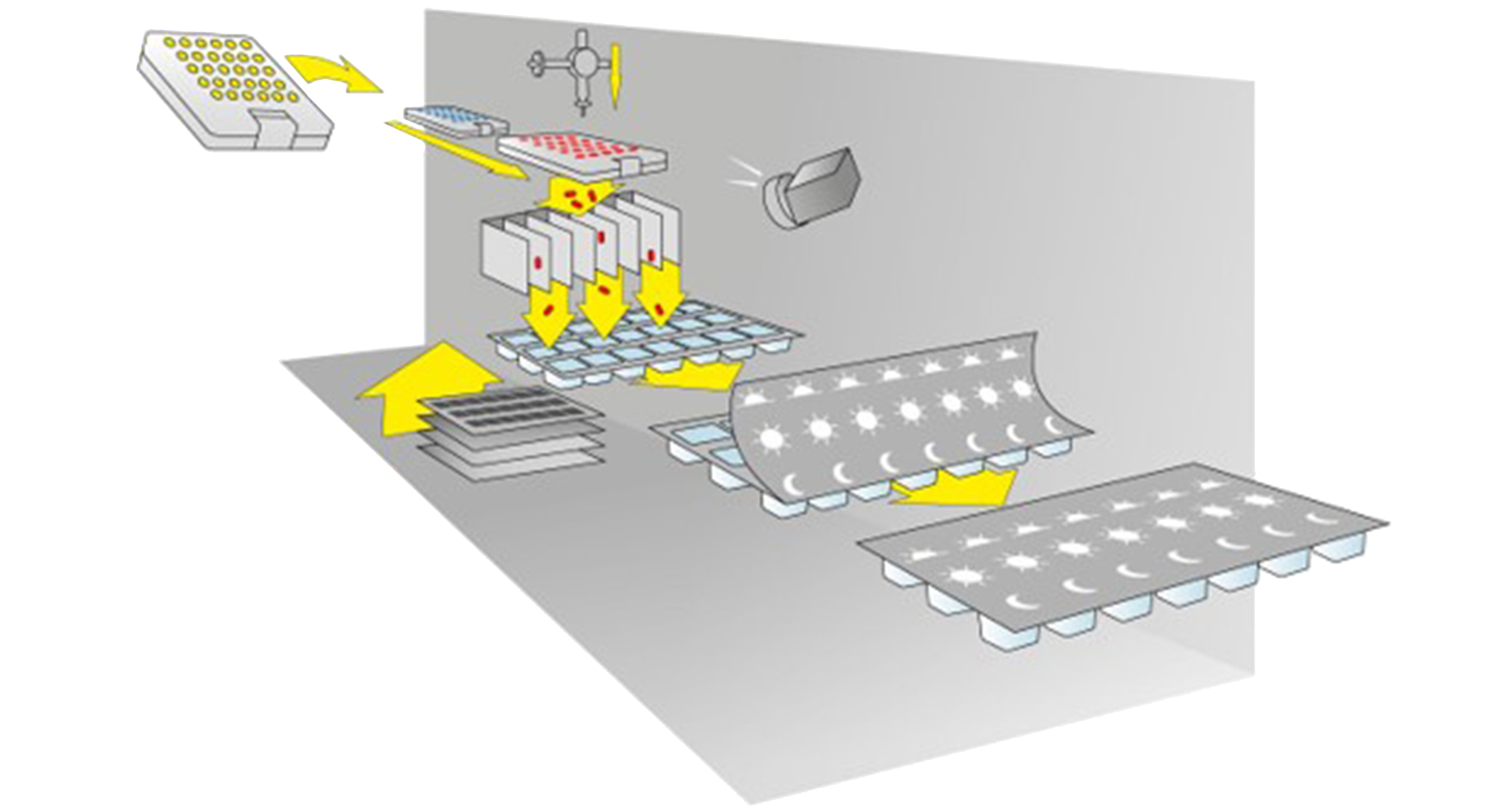

How the D3 Daily Dose Dispenser packs patient blister cards

Current solutions require multiple manual steps to pick tablets into patient-specific blister packs. With the Daily Dose Dispenser, only one manual step is left. The blister packing machine takes care of everything else fully automatically. We explain step for step how tablets are transferred from their original blister packs to the patient blister cards.

- Original blister packs are stabilized for the automatic process

- Contents are uniquely identified

- Any desired additional data, e.g. lot, process parameters and current quantity, is saved

Advantages

- No previous deblistering necessary

- No clean room conditions required

- No premature expiration of the medicine

- Tablets are stored in original blister packs until they are used

- Special blister trays can be filled with halved tablets

- Tablets are traceable back to their serial number

- 7,000 trays / medication types with 30 tablets each can be stored in 10 m2 (107 ft2)

- Up to 820 load carriers per blister production module

Advantages

- 100 % lot tracking

- 100 % traceability of serial numbers

- Theoretically unlimited amount of buffer space in passive storage

- The right punch is automatically selected

- Precise, reliable dispensing thanks to deblister punch

Advantages

- 100 % quality control for every dispensed pill

- 100 % quality control of final blister card

- No cross-contamination

- Seal and cover sheets attached

Advantages

- Customer-specific printing

- Administration instructions and additional information

- Easy to check which medicine has been taken

D3 blister packing machine: Key facts

Your value chain tech partner for one-stop healthcare solutions

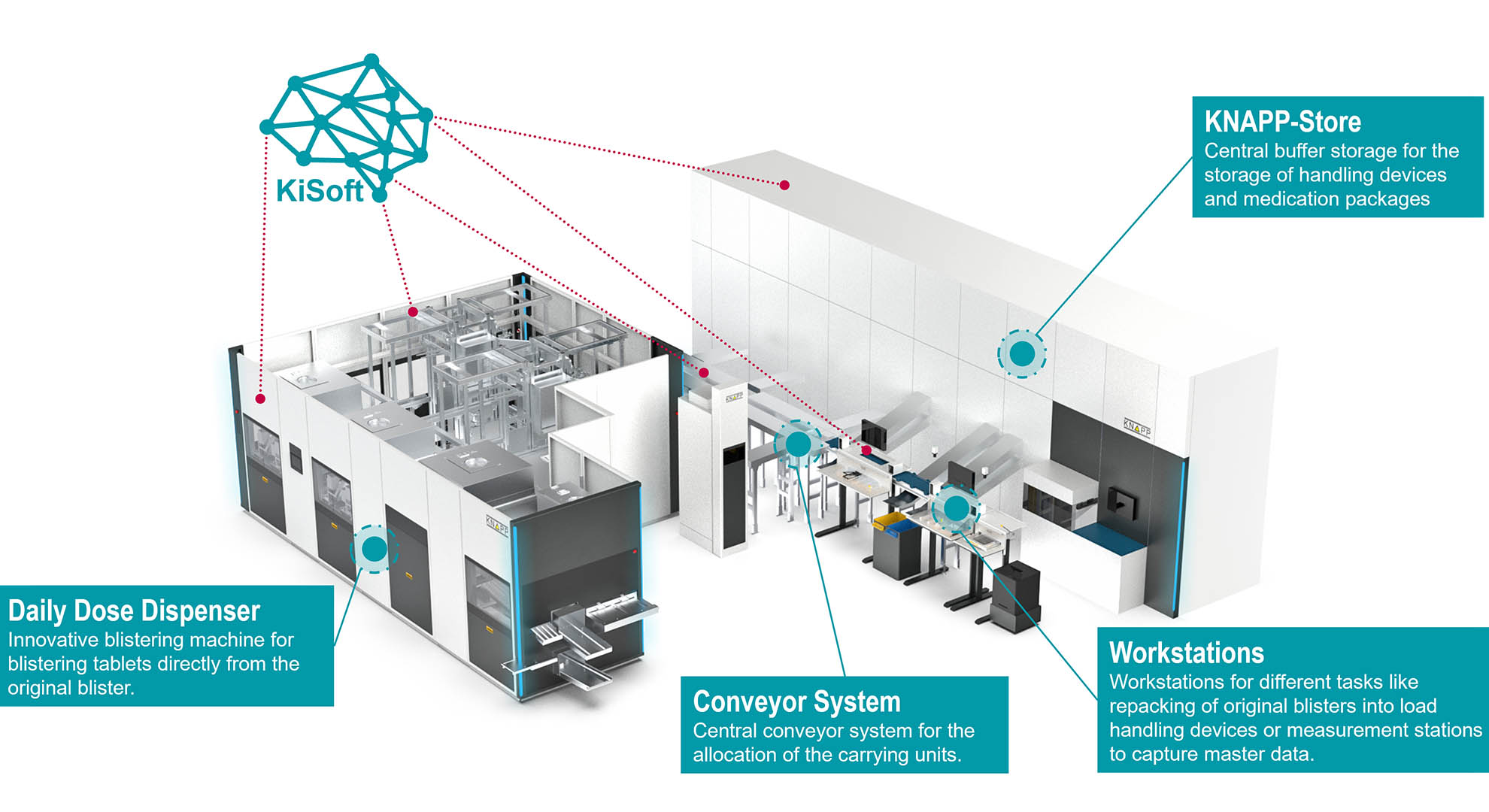

At KNAPP, we’ve been a partner of the healthcare industry for over 70 years. Our D3 system has a clear mission: We want to create maximum benefits for patients and their families while ensuring that blister centers and pharmacies are operating at top efficiency. D3 Daily Dose Dispenser is not just a blister packing machine, but an all-in-one solution encompassing software, service and continuous support.

Do you have any questions about the D3 Daily Dose Dispenser blister packing machine?

Want to read more about healthcare? Check out our blog posts:

From 24/7 pickup to custom delivery: our market-specific system solutions for pharma logistics focus on fulfilling patients’ needs. A blog post about last mile solutions for pharmacies.

For healthcare, textiles and fashion, retail, e-commerce and omnichannel retail, food retail and production, we offer flexible and creative solutions for the last mile. Our intelligent software works behind the scenes to keep things running smoothly. Together with our customers, we optimize their value chains.