When optimizing the entire logistics operation of a business, the supply chain is often the center of attention. But what about the value chain? How does that fit into the picture? Is there even a difference between value chain and supply chain? In this article, you'll learn why a change in perspective can be crucial and what these terms really mean.

Yes, there is. The value chain includes all business activities that create customer value. The more business activities are tailored to suit the customer’s needs, the higher the perceived value. An integral part of these activities is the flow of materials and immaterial goods. And this is where the supply chain comes in. The more smoothly and efficiently the goods flow the more they are available. And because the exchange of goods increases customer value, the supply chain is essential to the value chain.

But from the perspective of a supply chain manager, head of logistics or operations director, what makes more sense: optimizing the supply chain or enhancing the value chain? We’ve summed up the most important differences between the value chain and the supply chain below.

What is a supply chain?

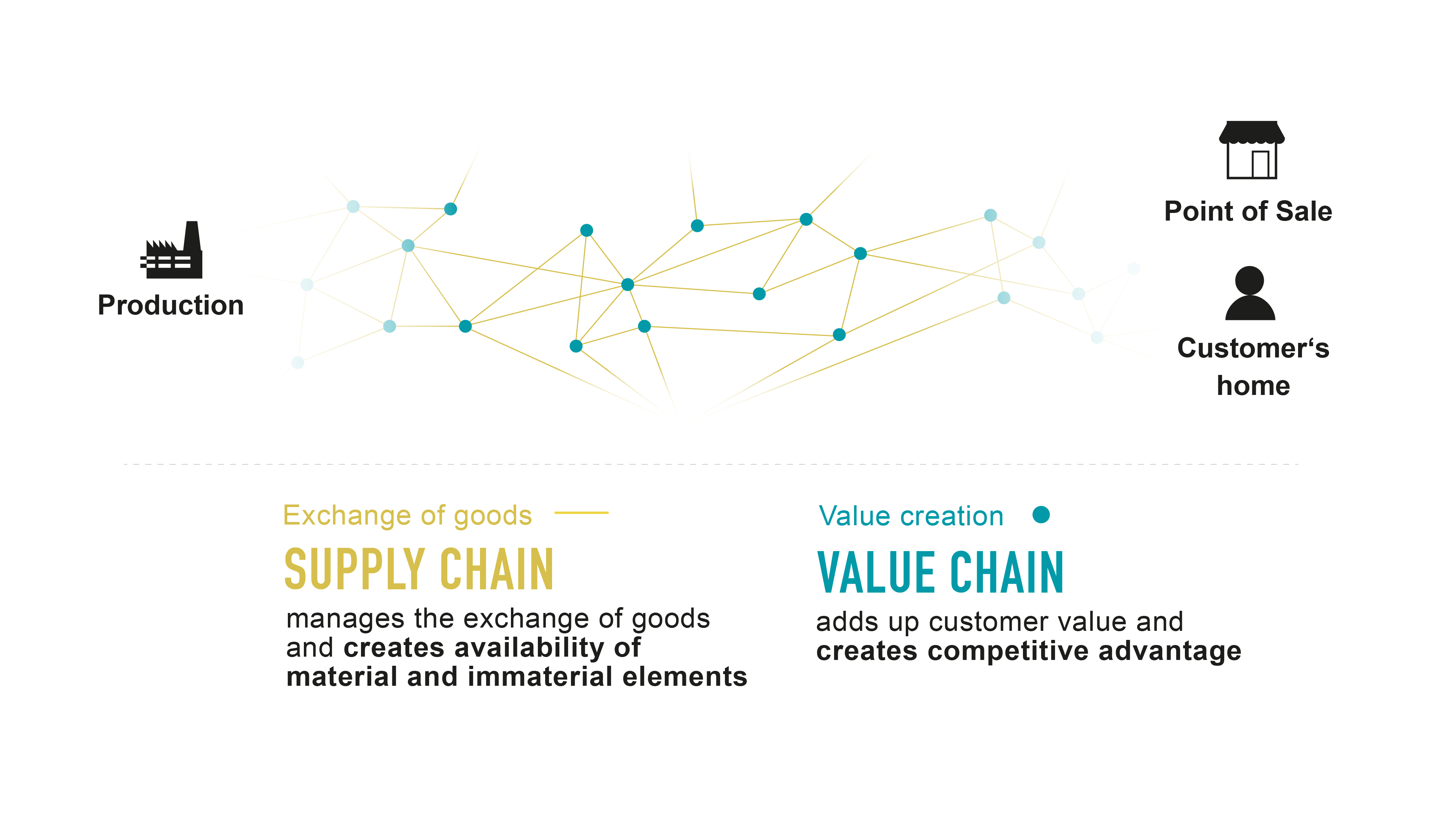

The supply chain starts with the first step in production and ends when the finished product has been delivered to the customer. What lies between production and the customer is a complex web of intersections through which materials and immaterial goods flow, such as raw materials and finished goods, services and information – including money.

A classic version of a supply chain covers goods exchange across production and distribution, all the way to the point of sale and even includes the last mile. Every step of the process is important to ensure that the right product is delivered to the right place at the right time.

Supply chain example:

A customer buys a computer

Before a PC arrives at the customer’s home, it’s had a number of stops along a fascinating journey. The journey first starts with mining raw materials, which are then refined and processed to become components. The components are then assembled, creating a finished computer.

But this is only half the story. The computers are then collected in central warehouses and shipped to stores or directly delivered to the consumer. Keeping this process running smoothly requires a constant flow of various kinds of information, such as delivery times, stock levels and payment flows, between the different steps along the supply chain.

However, this is not the final link in the supply chain. After delivery, services such as repairs and after-sales support also play an important role in making sure the customer not only gets both the product they wanted but also a pleasant experience.

The goal of the supply chain:

Making the goods flow extra efficient

At its core, supply chain management is all about making the exchange of goods as efficient as possible. This means that cost, quality and time factors are all optimized, either individually or in combination. Ideally, you can increase quality while reducing both costs and delivery times.

The key question is:

What is being exchanged - and how?

The supply chain is not just about the flow of goods, but of information, services and money too. If you manage to control these streams in a smart way, your customers will be satisfied and your company successful.

What is a value chain?

As with the supply chain, the value chain starts with production and ends with the customer. But while the supply chain organizes the exchange of goods, the value chain covers all business activities that create value for the customer. The are numerous interconnections and nodes along the value chain where value is generated. These points can be locations, companies, people or digital systems.

Value chain example:

A customer buys a new computer

A customer wants a new computer and is concerned with three things: performance, availability and price. Imagine the customer wants a computer with a fast processor so that they can edit videos and they want it at a reasonable price – fast delivery included.

This is what the value chain is all about. It allows you to give the customer exactly what they want, as all processes in the value chain are aimed at maximizing value – from product development (fast processor) to production and logistics (fast availability) to marketing and product pricing (reasonable price). However, the value chain does even more. Additional services such as adding a repair kit increase the perceived value of the product and creates a positive customer experience.

Every activity – whether tangible or behind the scenes – helps get the customer what they want: the right product, at the right time, at the right price – plus added value.

The goal of the value chain:

More value for the customer

Value chain management focuses on generating value for the customers. However, many things influence it such as trends, the overall state of the economy, influencers and the weather. When optimizing the value chain, the goal is therefore not just to create but to increase the customer value. Ideally, the product has a USP that gives the company a competitive edge.

The key question is:

How do you generate value – and what for?

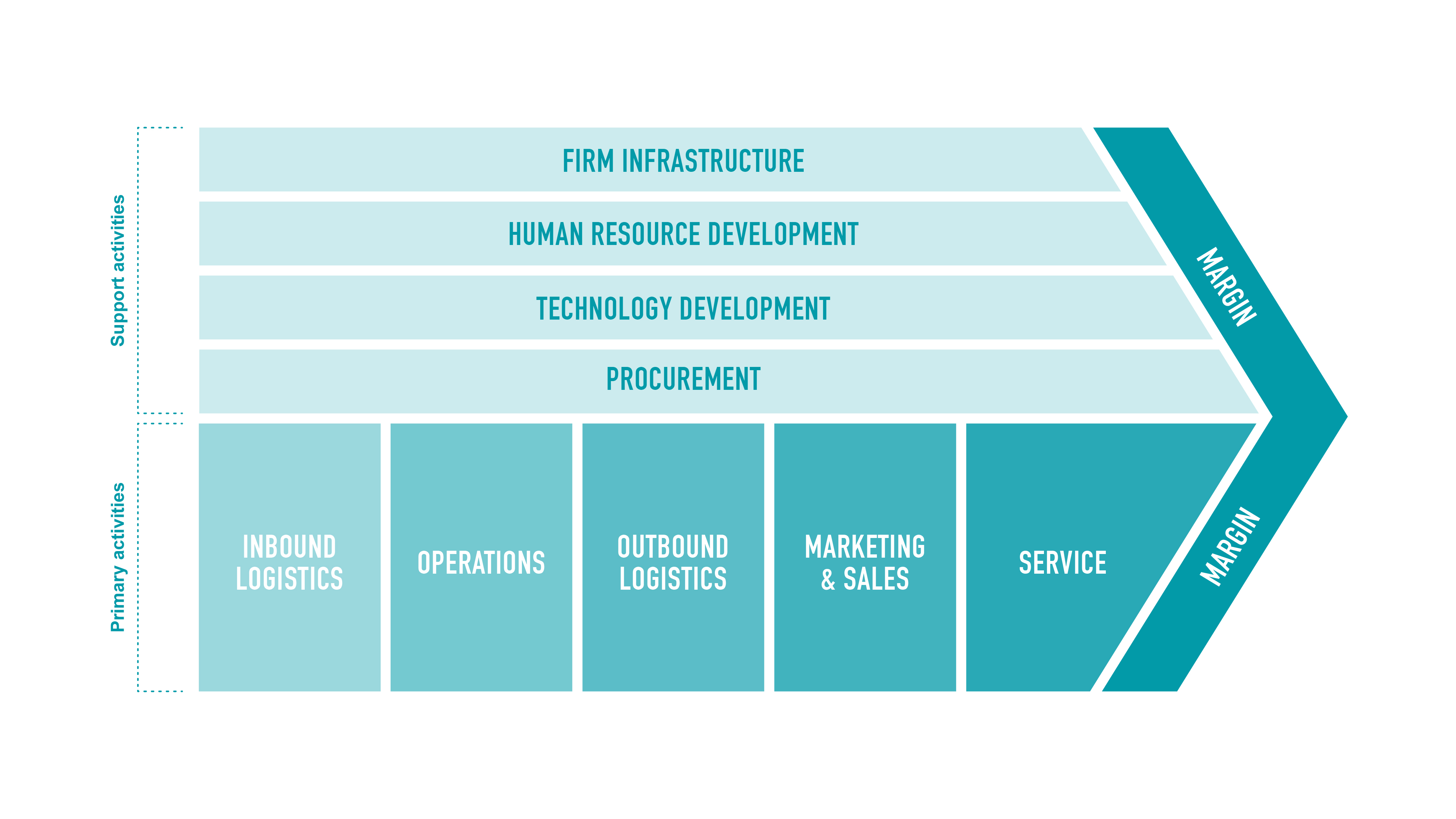

The value chain is a large network stretching across all the companies involved with their business activities – manufacturing, distribution, sales and beyond – but every business also has its own value chain. One proven model that analyzes the functions within individual companies is the value chain model by Michael E. Porter.

This model breaks down the value chain into primary and supporting activities:

Primary activities:

- Inbound logistics

- Operations

- Outbound logistics

- Marketing and Sales

- Service

These activities generate value directly.

Supporting activities:

- Firm infrastructure

- HR development

- Technology development

- Procurement

These activities make primary activities possible.

Every company needs supporting activities to enable them to perform their primary activities. In this model, the exchange of goods (represented by inbound and outbound logistics) is absolutely essential for generating customer value.

Value chain vs supply chain – the difference at a glance

The value chain is a network of all business activities stretching from production to the end customer that generate customer value. Customer value is created across the many nodes and interconnections in this network. Ideally, the sum of these values, collectively often called “value proposition”, gives companies an advantage over competitors.

The supply chain, on the other hand, controls the exchange of goods between the nodes and ensures the availability of material and immaterial elements. And because the exchange of goods also increases customer value, the supply chain is part of the value chain.

Key takeaway: While the value chain is the strategic framework for generating value, the supply chain focuses on implementation at an operational level. Together, they create an optimized customer experience.

Direct comparison:

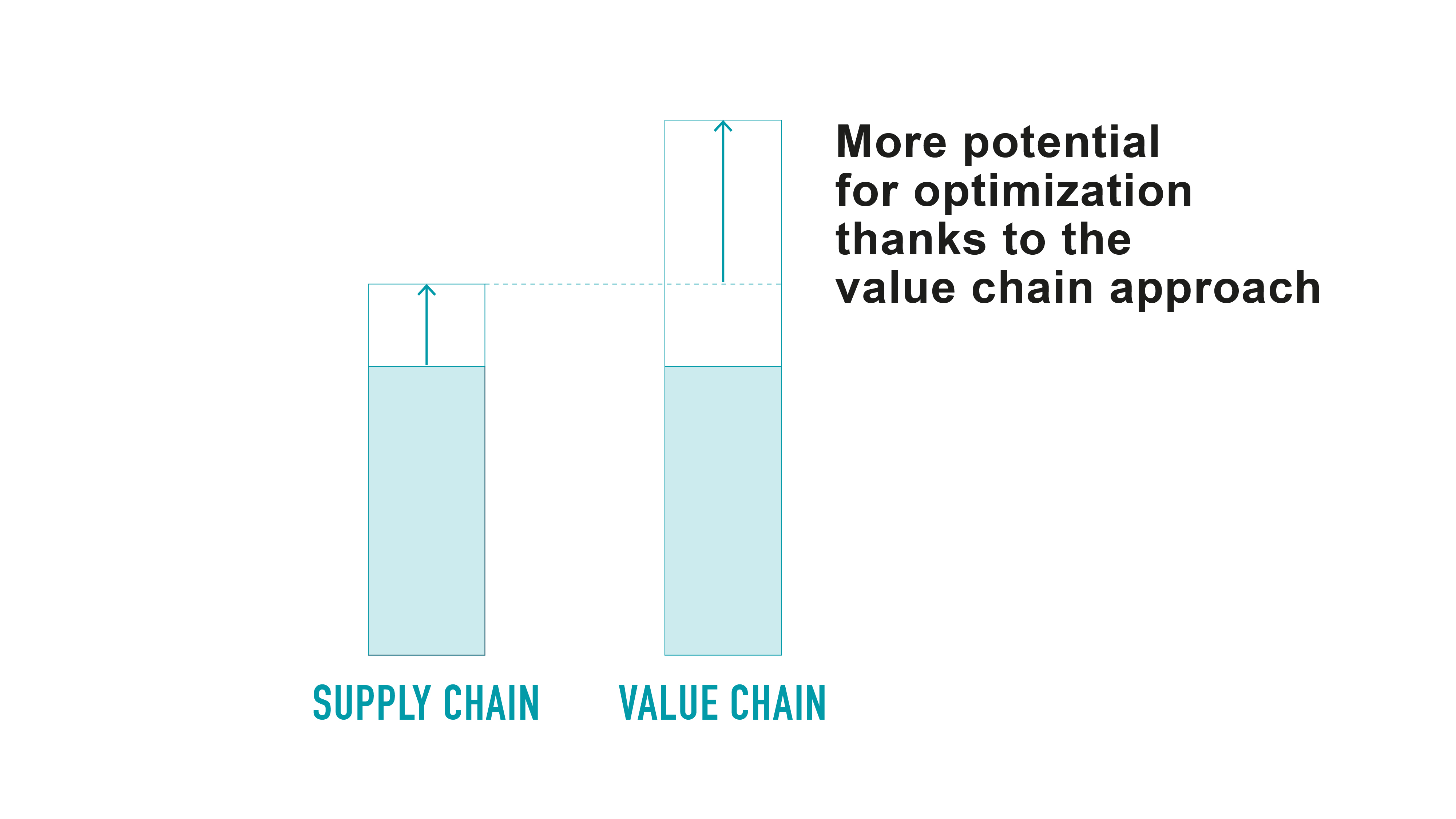

The bottom line: thinking in terms of the value chain opens up new opportunities for optimization

The value chain covers all business activities – whether material or immaterial – that create customer value. When comparing classic supply chain models with the value chain approach, it quickly becomes clear that thinking in supply chains is only half the story as they primarily focus on the physical exchange of goods and overlook how immaterial value is generated. This limited view was long sufficient since, for decades, customer value was created primarily in production and with efficient distribution. However, there has now been a fundamental shift towards the importance of information as an immaterial customer value.

Today, customers expect products to be tailored to their individual lives and should hold the solution to specific problems. Customers want to be informed and included in the process, giving them the possibility to engage. This means that a lot of information needs to flow between companies and customers, which influences production, logistics and service.

There’s a clear winner in the value chain vs supply chain comparison!

Thanks to the broad value chain approach, the possibilities for designing and optimizing processes are endless and go far beyond just the flow of materials, paving the way for new technologies, innovative business models and future-proof employee skills. In today’s world, looking at the value chain from a strategic perspective – as a network and means to generate customer value, not as a chain of separate processes – is a catalyst for success.

There’s a clear winner in the value chain vs supply chain comparison!

Thanks to the broad value chain approach, the possibilities for designing and optimizing processes are endless and go far beyond just the flow of materials, paving the way for new technologies, innovative business models and future-proof employee skills. In today’s world, looking at the value chain from a strategic perspective – as a network and means to generate customer value, not as a chain of separate processes – is a catalyst for success.

At KNAPP, we feel right at home in this new world of possibilities. As a value chain tech partner, we strive to harness the full potential of value chains together with our customers, helping them boost their success.

Interested in optimizing your value chain? Get in touch with us!