Picking Robot for Highly Automated E-commerce Fulfillment

eMAG is the leading e-commerce platform in Romania, Bulgaria and Hungary. The company offers their customers a broad range of products from electronics and clothing, but also books, toys and furniture. To be better able to handle the rising demands for service and efficiency, eMAG built a state-of-the-art e-commerce logistics system near Bucharest in 2021 using KNAPP technologies.

Originally, picking was a completely manual process, but when the company was faced with growing order volumes, they found themselves increasingly at their limits, especially during peak periods. Combining a fully automatic warehouse having shuttles and picking robots with the manual warehouse areas made processes smooth, efficient and virtually error-free.

44.600 m² / 480,070 ft² automated storage area

up to 15,000 orders per hour

1 million SKUs

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWe were satisfied with KNAPP’s e-commerce expertise and tailored solution.

Bogdan Solomon

Project Manager, eMAG

Would you like to re-align your value chain?

Contact our experts today.

E-commerce logistics solution chalks up success and more

Fast order processing

High storage capacity

Error-free order processing

Employee-friendly working conditions

Continuous system operation

Flexibility for future growth

Our customers directly benefit from the KNAPP solution through more precise order fulfillment and faster delivery.

Marian Voicu

Warehouse Manager, eMAG

Curious about logistics automation?

Contact our experts today.

The perfect logistics mix for eMAG

1) Goods-in

eMAG’s goods are delivered to the warehouse on pallets and then allocated either to manual or automatic processing areas. For the automated storage system, the goods are placed in containers at the decanting station, with different containers available for the different types of merchandise. The empty containers are automatically supplied from the empty container buffer. Once filled, the containers are either directed into the Evo Shuttle 1D automated storage system or to the manual warehouse. Empty packaging is automatically transported to the waste disposal area.

2) Automated storage

The automated small parts warehouse Evo Shuttle 1D allows putaway and retrieval cycles of up to 12,780 containers per hour. The 432 shuttles are busy in 18 aisles on 24 levels, accessing the 131,088 storage locations within the racks. There is one shuttle per level in each aisle. The containers ride the lift to get from their level in a rack line system down to the pre-zone where they are diverted into the powerful AAA Loop, a conveyor loop from which they continue in sequence for picking. The space-effective AAA Loop is connected to all of the rack line systems and has a throughput of about 11,700 containers per hour.

3) Manual storage

Goods that are too large or that do not fulfill the storage requirements for the automatic storage system are stored in the manual warehouse area. Here, picking is carried out manually using RFID readers, providing end-to-end tracking. In this warehouse area, orders are picked manually, usually in batches. From the manual area, these orders are automatically conveyed away via take-away conveyor and lift. Orders with mixed storage sources are combined at consolidation stations, where the automatically picked items are consolidated with the manually picked items of an order.

4) Technology supports picking

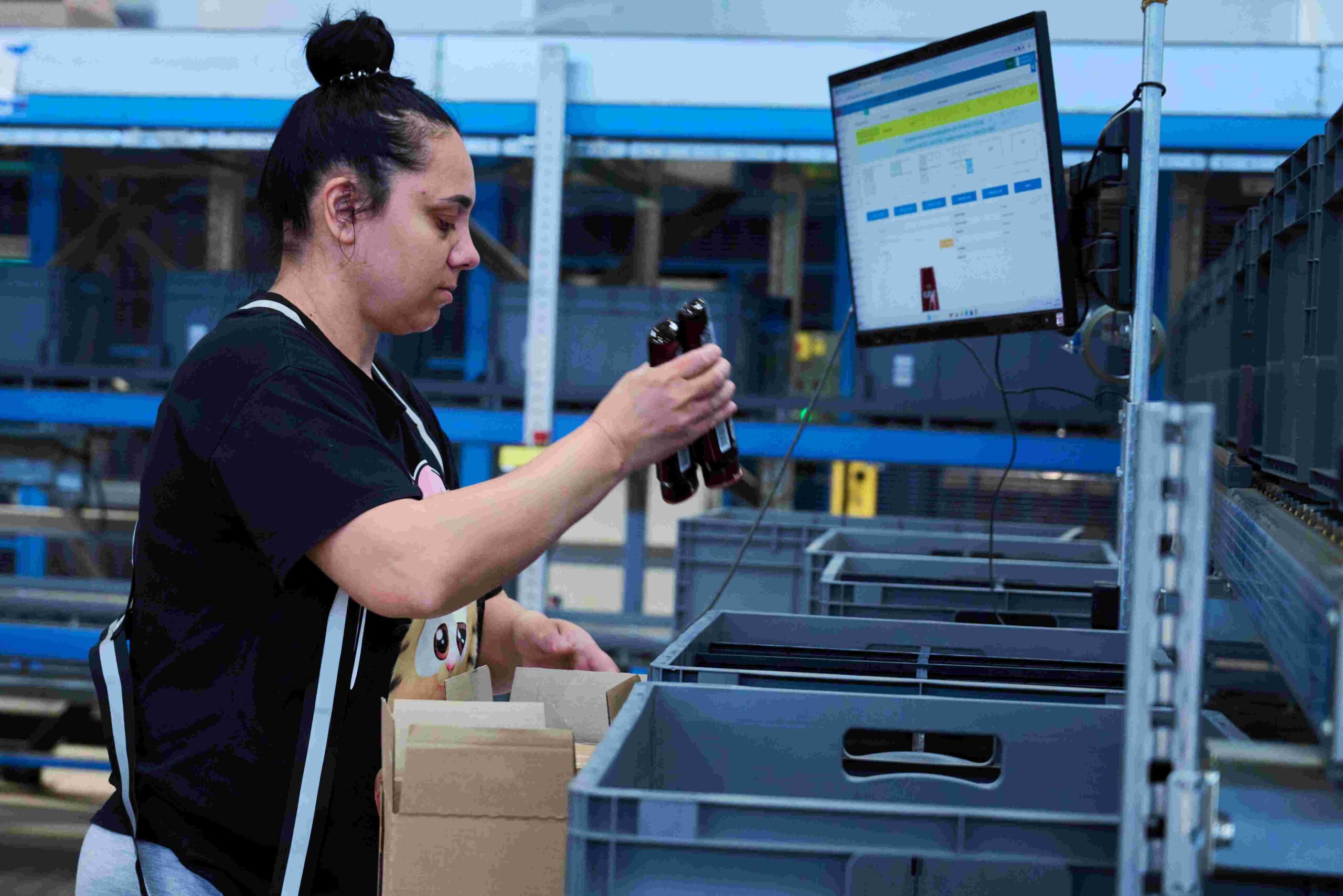

After order receipt, the required containers are automatically retrieved from the Evo Shuttle 1D and conveyed to one of the 29 goods-to-person work stations of the Pick-it-Easy Evo series, which have two source container bays and four target container bays. The employee completes the picking process guided by lights and screens. Containers flow in and out of the work station continuously for high capacity and minimum waiting time. The ergonomic station is also used to conduct inventory and to correct errors.

3) Fully automatic picking

eMAG uses the Pick-it-Easy Robot for even more efficiency, which automatically picks the single-item orders typical for online retail, with up to 600 picks per hour. Thanks to AI-supported object recognition and grip point calculation, the robot can gently pick a broad array of items with very different shapes, from clothing to sensitive cosmetics.

5) Consolidation and packing

Orders with items coming from different storage areas are assembled at the consolidation stations and then packed at ergonomically designed packing stations. Orders arrive at the pack station on three levels of conveyors. The orders are packed into cartons, envelopes or polybags depending on what is needed, and additional paper is added to secure the orders for transport. Empty containers are automatically stacked and returned to the empty container buffer for picking containers.

6) Sorting and shipping

After packing, the orders enter the cross belt sorter, either manually fed or from the spiral conveyor. The packages are sorted by delivery region at a rate of 15,000 packages per hour. The packages land in the shipping containers via one of 74 chutes, providing rapid reliable delivery for eMAG customers.

1D Shuttles

double cycles

Pick-it-Easy Robot

automatic picks

Smart warehouse for E-commerce efficiency

In eMAG’s automated warehouse, software is more than just a tool; it forms the central nervous system of the entire logistics solution. It interconnects machines, processes and people, forming an intelligent system that learns, makes decisions and optimizes in real time. The Pick-it-Easy Robots are truly amazing: Using AI and machine learning, the robots learn new items, determine precise grip points and adapt their speed automatically. The machine learning allows the system to save the information it has gained and to apply this information again. The result is efficient, scalable and automated e-commerce fulfillment at eMAG.