Fashion Logistics:

Tailor-Made Logistics Solutions for Your Industry

Fast fashion trends, a high return rate and ever-increasing customer expectations are making the fashion industry a highly dynamic environment. By automating your fashion logistics, your company will benefit from flexibility, efficiency and reliable deliveries – making sure you’re always one step ahead of the competition.

Future-proof textile logistics catering to the fashion industry

In order to be successful in a fast-paced environment, like the fashion industry, retailers require high-performance fashion logistics. Logistics processes need to allow players to act and respond quickly, flexibly and reliably across all channels as retailers are faced with a number of challenges such as short product life cycles, seasonal peaks, high return rates and the balancing act between online and brick and mortar retail. This is where cutting-edge fashion logistics automation comes into play, providing agility and resilience for efficient textile logistics.

Our fashion logistics solutions accelerate processes, minimize errors and ensure you can deliver across all your sales channels. Whether you’re looking for store-friendly delivery, intelligent returns management or next-day delivery, our scalable systems grow along with your requirements. We design our systems with the end consumer in mind because a great customer experience starts with automated logistics.

We understand the fashion industry and its challenges. We are your partner for intelligent, future-proof fashion logistics.

Johannes Holas,

Vice President Fashion Solutions, KNAPP

Have we sparked your interest?

We’re happy to answer all your questions.

Email: sales@knapp.com

#passion4fashion

Are you interested in efficient logistics automation for the fashion industry?

We help renowned fashion brands succeed

Our fashion logistics solutions

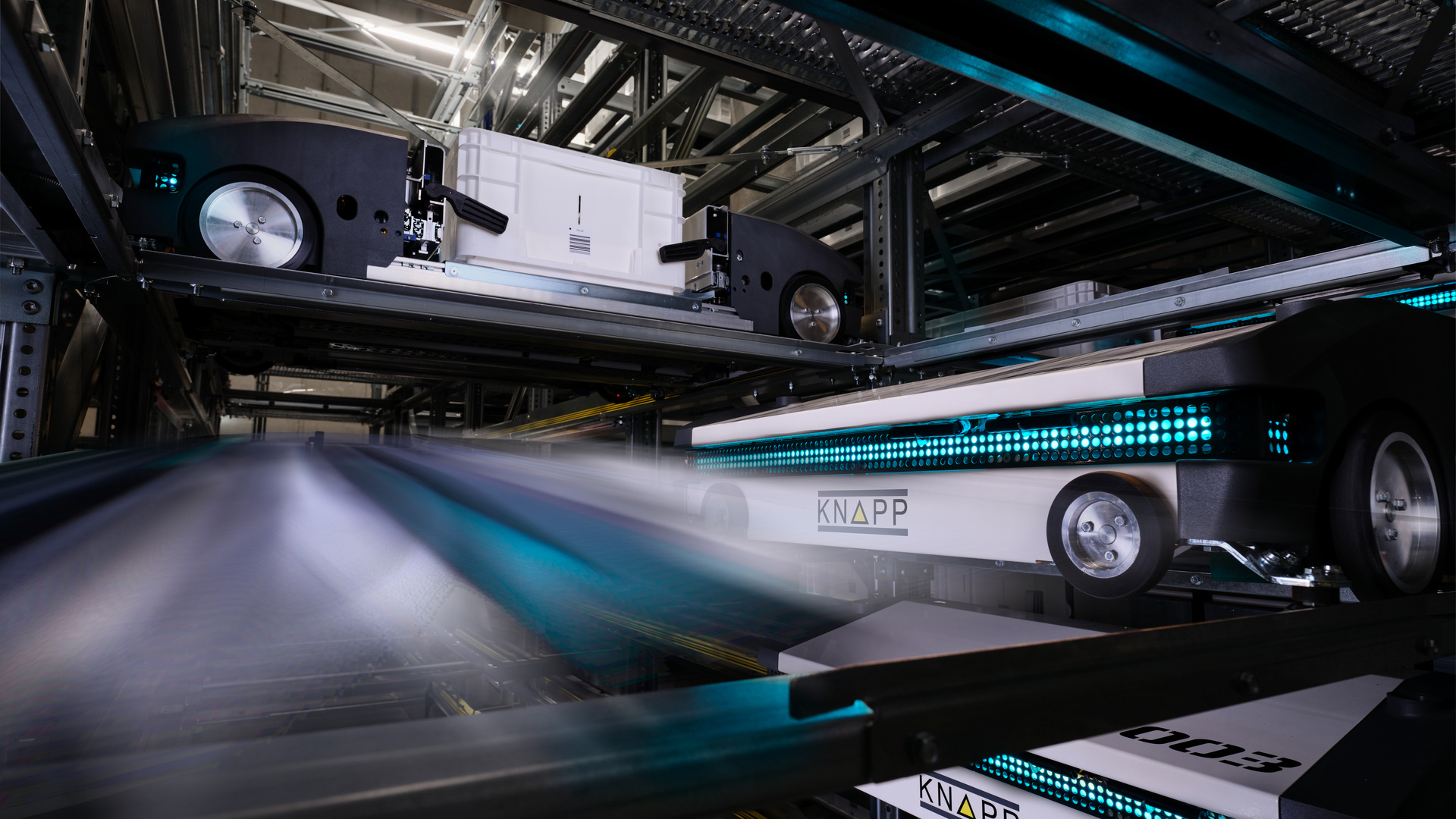

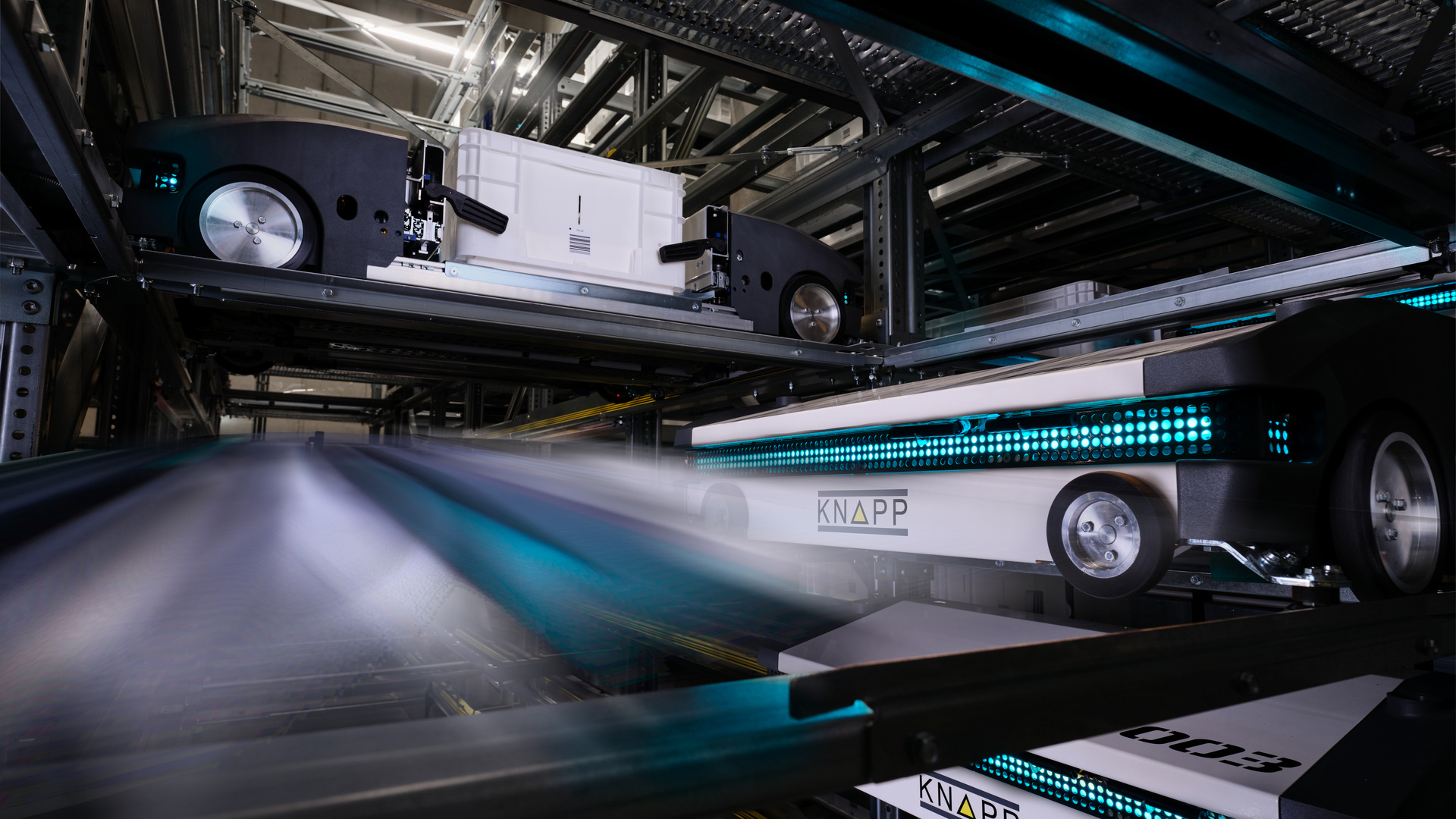

Automated storage and retrieval systems for fashion companies

From our shuttle solutions to bot systems and stacker cranes, all of our automated storage and retrieval systems are tailored to the requirements of the fashion sector. They quickly pick, buffer and sequence textiles, shoes and accessories.

Learn more about our selection of efficient storage and retrieval systems:

Conveying, sorting and handling fashion items

We offer a comprehensive solution portfolio for efficiently conveying, sorting and handling fashion and sporting goods. It includes everything from solutions for hanging and flat-packed goods to pocket sorters for returns and high-speed shipping sorters.

Find out more about our flexible systems:

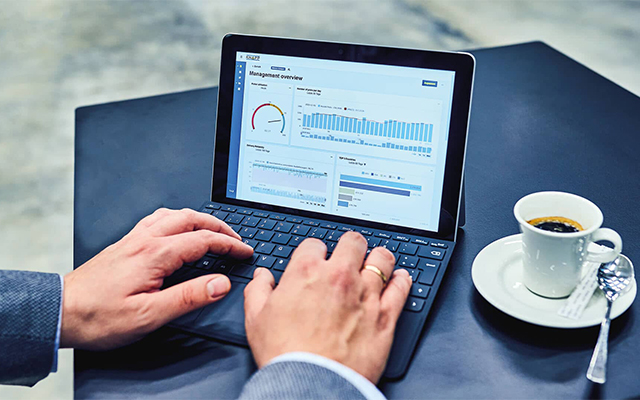

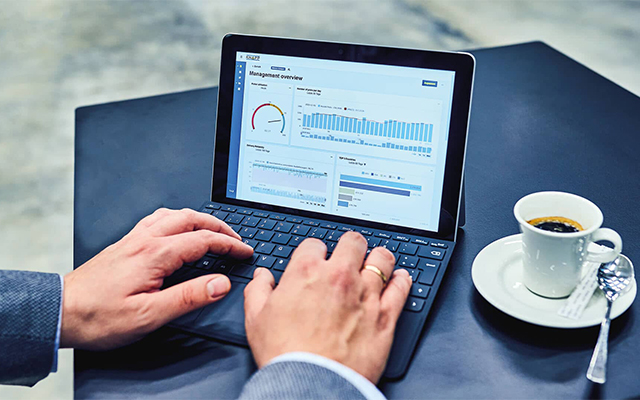

Software designed for fashion logistics

Our software provides central, intelligent control of all processes in the fashion warehouse from goods-in to goods-out and beyond. Whether you need a WMS, WCS, machine control system or software for analysis and resource planning, our software products let you stay on top of your processes and optimize your entire fashion supply chain.

Find out more about our digital solutions and software:

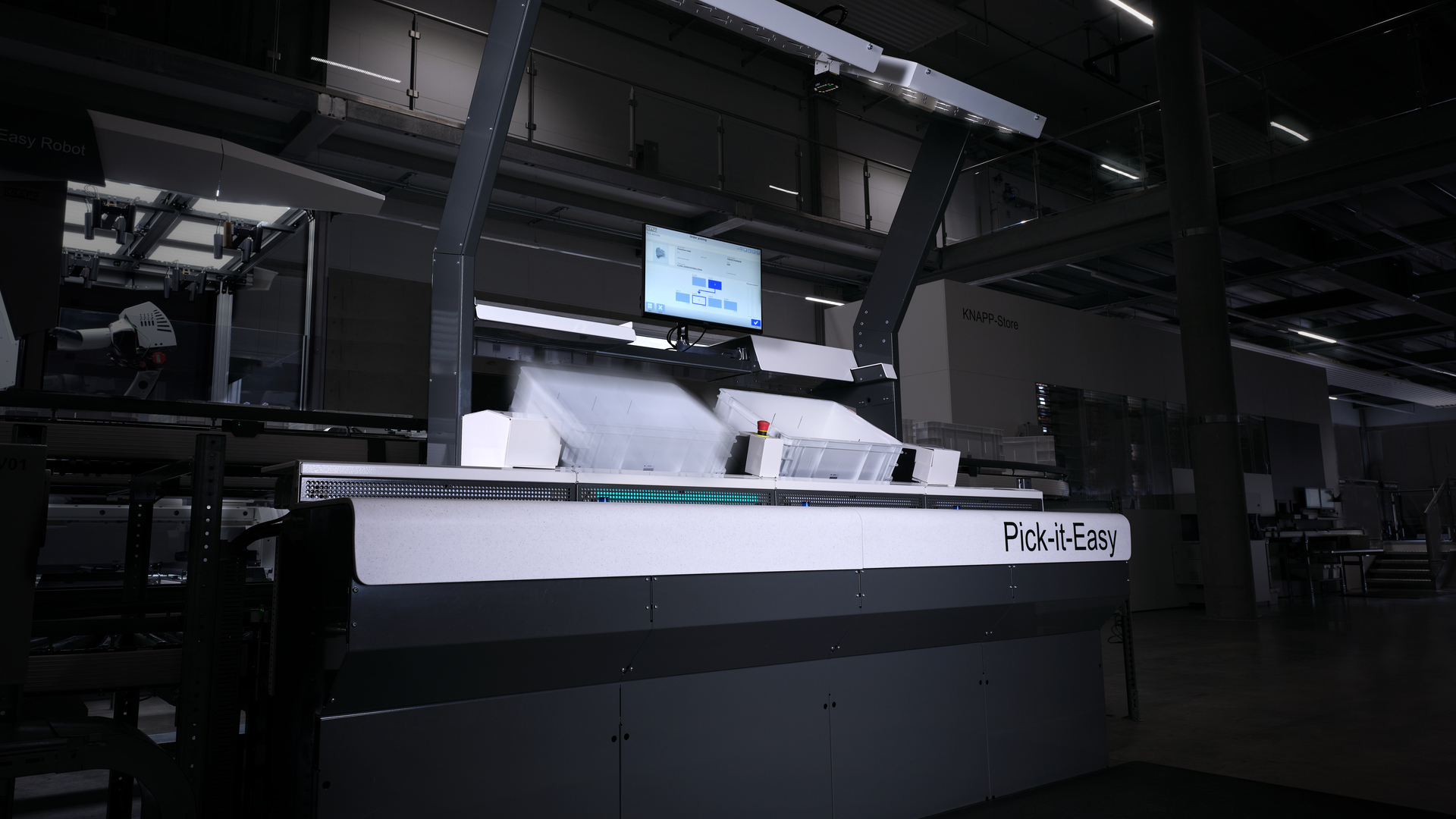

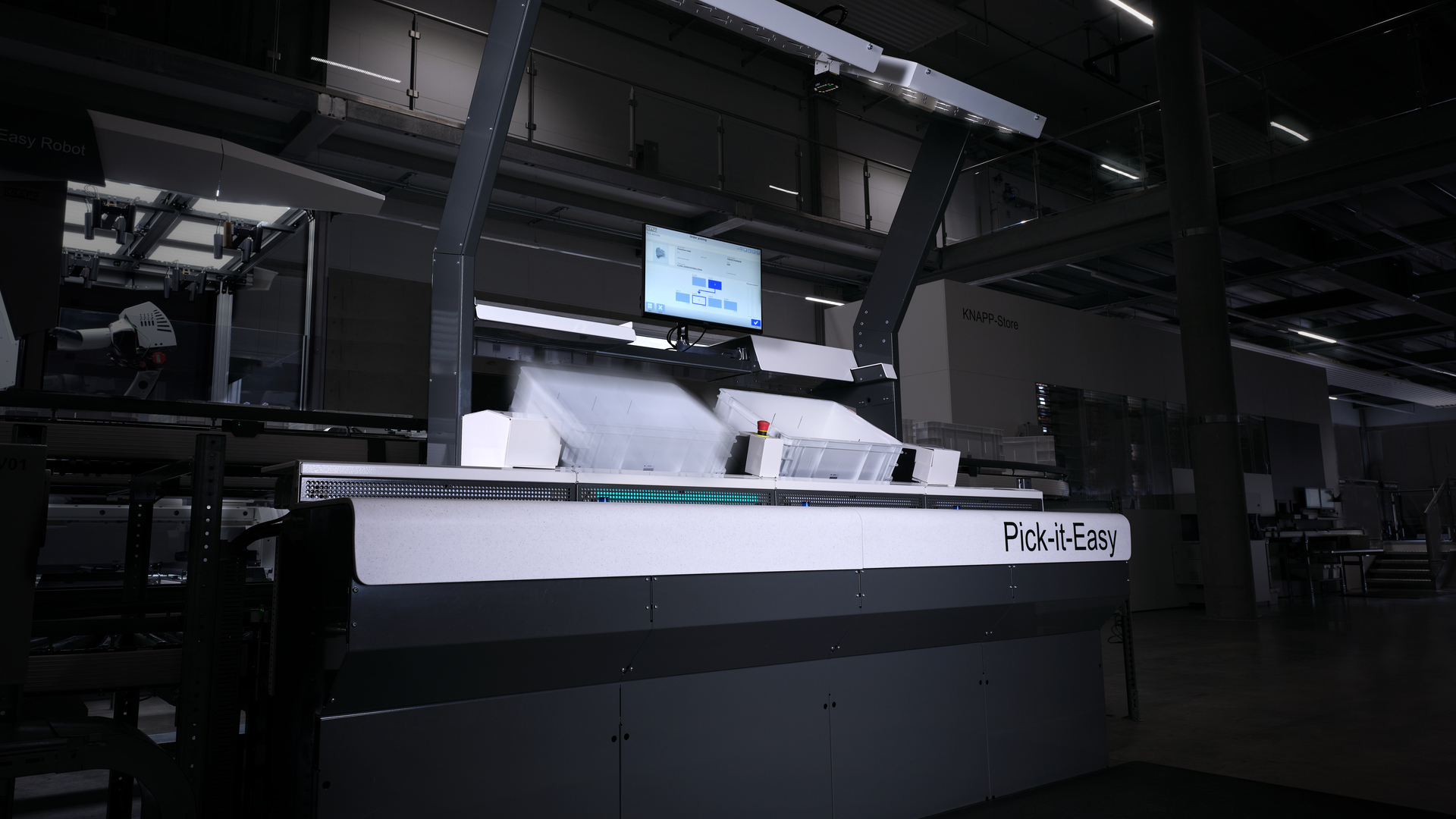

High-tech work stations for fashion warehouses

Our sophisticated work stations combine ergonomic design with intelligent guidance through processes such as efficient picking and returns handling. Since the stations are connected directly to the automatic systems, items arrive just in time, shortening walking distances, reducing errors and boosting efficiency.

Find out more about goods-to-person picking:

Robots for automated textile logistics

With our robot solutions for bin picking, full-case picking and autonomous transport, we’re upping the efficiency in fashion warehouses. Our systems take the strain off your employees and ensure performance is consistently high – even as volumes grow.

Learn more about robotics and AI:

Our fashion logistics solutions

Automated storage and retrieval systems for fashion companies

From our shuttle solutions to bot systems and stacker cranes, all of our automated storage and retrieval systems are tailored to the requirements of the fashion sector. They quickly pick, buffer and sequence textiles, shoes and accessories.

Learn more about our selection of efficient storage and retrieval systems:

Conveying, sorting and handling fashion items

We offer a comprehensive solution portfolio for efficiently conveying, sorting and handling fashion and sporting goods. It includes everything from solutions for hanging and flat-packed goods to pocket sorters for returns and high-speed shipping sorters.

Find out more about our flexible systems:

Software designed for fashion logistics

Our software provides central, intelligent control of all processes in the fashion warehouse from goods-in to goods-out and beyond. Whether you need a WMS, WCS, machine control system or software for analysis and resource planning, our software products let you stay on top of your processes and optimize your entire fashion supply chain.

Find out more about our digital solutions and software:

High-tech work stations for fashion warehouses

Our sophisticated work stations combine ergonomic design with intelligent guidance through processes such as efficient picking and returns handling. Since the stations are connected directly to the automatic systems, items arrive just in time, shortening walking distances, reducing errors and boosting efficiency.

Find out more about goods-to-person picking:

Robots for automated textile logistics

With our robot solutions for bin picking, full-case picking and autonomous transport, we’re upping the efficiency in fashion warehouses. Our systems take the strain off your employees and ensure performance is consistently high – even as volumes grow.

Learn more about robotics and AI:

Curious about more solutions for fashion logistics?

Benefits for fashion logistics

Our automated logistics solutions for the fashion sector offer plenty of advantages:

Efficient returns management

Managing seasonal peaks efficiently

Shop-friendly Delivery

Next-Day-Delivery & fast delivery times

Scalable solutions for growing businesses

Omnichannel fulfillment from one warehouse

References:

Successful customer projects in fashion logistics

Tempe Inditex: Automated store fulfillment for accessories and more

Tempe Inditex supplies brands such as Zara and Bershka with accessories, shoes and handbags. Using AutoPocket increased the company’s warehouse performance and employee productivity, even when there’s a lot of sorting to be done.

ASOS: Data-driven logistics with KiSoft Analytics

ASOS, an online fashion retailer, rounds out their German logistics center with intelligent logistics software. Integrating KiSoft Analytics has improved transparency, analyzability and operational efficiency.

Luxottica: Global omnichannel distribution

Luxottica, a provider of exclusive eyewear and fashion brands, optimized their global supply chain with a highly automated omnichannel distribution center that combines shuttles, automated picking systems and robots in one central system.

DSV: Tailor-made omnichannel fashion logistics

As a 3PL provider, DSV runs a distribution center for a well-known sporting goods manufacturer. Our flexible automation solution provides error-free order fulfillment for DSV’s customers across all their sales channels.

Next plc: From split tray to pocket sorter

British fashion retailer Next opted for AutoPocket to increase their efficiency, save on personnel and provide better service. The new system replaces their old split tray sorter and makes outbound tasks such as sequencing and sorting for online retail more efficient.

Celio: Proven technology for dependable store delivery

French fashion retailer Celio has been using our split tray sorter to sort flat-packed goods for store delivery since 2012. The result? Optimized processes, increased efficiency and a consistently high service level.

References:

Successful customer projects in fashion logistics

Tempe Inditex: Automated store fulfillment for accessories and more

Tempe Inditex supplies brands such as Zara and Bershka with accessories, shoes and handbags. Using AutoPocket increased the company’s warehouse performance and employee productivity, even when there’s a lot of sorting to be done.

ASOS: Data-driven logistics with KiSoft Analytics

ASOS, an online fashion retailer, rounds out their German logistics center with intelligent logistics software. Integrating KiSoft Analytics has improved transparency, analyzability and operational efficiency.

Luxottica: Global omnichannel distribution

Luxottica, a provider of exclusive eyewear and fashion brands, optimized their global supply chain with a highly automated omnichannel distribution center that combines shuttles, automated picking systems and robots in one central system.

DSV: Tailor-made omnichannel fashion logistics

As a 3PL provider, DSV runs a distribution center for a well-known sporting goods manufacturer. Our flexible automation solution provides error-free order fulfillment for DSV’s customers across all their sales channels.

Next plc: From split tray to pocket sorter

British fashion retailer Next opted for AutoPocket to increase their efficiency, save on personnel and provide better service. The new system replaces their old split tray sorter and makes outbound tasks such as sequencing and sorting for online retail more efficient.

Celio: Proven technology for dependable store delivery

French fashion retailer Celio has been using our split tray sorter to sort flat-packed goods for store delivery since 2012. The result? Optimized processes, increased efficiency and a consistently high service level.

FAQs - All about fashion logistics

Seasonal fluctuations, whether due to new collections, seasonal sales or trends are particular challenges in fashion logistics. Modern flexible, data-based processes can really help fashion retailers to manage these fluctuations, all while keeping focused on the consumer:

- Prognosis-based planning: By using data-based analyses, seasonal fluctuations in demand can be recognized early on so that the number of personnel, warehousing space and resources can be optimally adjusted.

- Optimized storage strategies: Seasonal best sellers and trending products are stored and picked in strategic locations in the warehouse to ensure rapid availability when demand is particularly high.

- Data-driven decisions: Having real time data available means processes can be continually analyzed and then flexibly adapted, for example, for optimizing routes or controlling storage capacities.

- Flexible use of the system: Storage and picking systems can be adapted dynamically to ensure efficient fulfillment for both brick and mortar and e-commerce. Both sales channels are served from a single warehouse stock.

- Efficient returns management: After a seasonal peak, the volume of returns rises. Automated processes speed up the return to storage and re-availability of the fashion items.

- Simulation and system check: Simulations help you identify and prevent potential bottlenecks. Regular system health checks ensure that it performs optimally and is equipped to handle seasonal fluctuations.

These measures help to keep fashion logistics stable, scalable and customer-oriented even during seasonal peaks, which provides a clear competitive advantage for fashion retailers.

In the fashion sector, sustainability plays an important role. By investing in intelligent processes and technologies that save resources, fashion retailers combine their ecological responsibility with economic efficiency:

- Eco-friendly packaging: The use of recyclable or biodegradable materials reduces the ecological footprint for shipping and returns of fashion items.

- Tailored packaging solutions: Precise packaging minimizes packaging waste and furthermore optimizes the use of space when transporting clothing and accessories.

- Efficient use of floorspace in the warehouse: Intelligent planning and compact warehouse designs reduce the amount of space required.

- Lifecycle management for systems: Existing logistics systems are modernized, saving resources and extending their service life.

- Optimized delivery routes: Smart route planning and using local micro fulfillment centers keep delivery routes short, reduce emissions and make deliveries to customers more sustainable.

- Sustainable returns processes: The efficient return and reconditioning of returns reduces waste and promotes a more circular economy in the fashion sector.

Such measures make fashion logistics more sustainable, strengthening the brand image of fashion retailers and fulfilling rising consumer expectations for environmental awareness.

For fashion enterprises, efficient reverse logistics is a central factor in success. The focus is on digital processes, automation, and data-based control for processing returns quickly, cost-effectively and, for the consumer, conveniently:

- Digital recording and inspection: Incoming shipments of returns are electronically recorded, inspected and reconditioned for resale in a transparent and traceable process.

- Automated refunds and re-integration into the warehouse: Refunds are automatically made as the returned fashion items are booked directly back into the warehouse.

- Flexible storage zones for fashion items: Seasonal best sellers and trend items are stored in dynamic buffer areas, from which these items are rapidly available for resale.

- Efficient storage of slow movers and surplus inventory: Items with less demand or seasonal items are space-effectively and systematically stored.

- Partially or fully automated processes: Depending on the number of returns, processes can be supported manually or fully automatically.

- Data-based analysis and prognosis: Intelligent software makes prognoses on returns, identifies trends and provides support in making strategic decisions.

These solutions not only make reverse logistics for fashion faster and more cost-efficient, but also more consumer-oriented and sustainable.

For fashion retailers, transport from the warehouse to the consumer – the last mile – is a crucial competitive factor and vital to customer satisfaction. Modern technologies and innovative logistics solutions can improve this process exactly as needed:

- Intelligent route planning: Routes are planned using software that takes the current traffic situation into account, which shortens not only delivery times, but also reduces CO₂ emissions.

- Digital delivery processes: The app guides the driver along the optimal route, and the delivery of the fashion item to the consumer is digitally documented for maximal transparency and tracking.

- Data-based process optimization: Analysis tools provide valuable key figures to continually improve deliveries.

- Automated storage and picking systems: Modern shuttle systems such as the Evo Shuttle ensure rapid, precise picking, quickly preparing fashion items for shipping.

- Micro fulfillment center: Small automated warehouses close to the city shorten delivery routes, facilitate same- or next-day-delivery and raise customer satisfaction.

- Space-saving, customized packaging: Customized packaging solutions reduce the volume of each shipment, allowing more orders to fit into a transport vehicle. In turn, this increases vehicle utilization and makes deliveries faster and more efficient.

These solutions make the last mile for fashion e-commerce not only faster and more efficient, but also more sustainable and consumer-oriented – a clear benefit for retailers and consumers alike.

Global service network and a reliable partner

Our International Customer Service looks after your logistics system – around the globe, around the clock, 365 days a year. Discover more about our services, from seamless support to optimizing your system!