Highly Automated Online-Fulfillment for All Temperature Zones

Due to the significant growth in Shufersal Online’s e-commerce sales, we developed a powerful solution for Shufersal in Modi’in.

The highly automated solution covers all temperature ranges while ensuring highest picking performance, short lead times and the best delivery quality. With the final expansion, our long-term partner is aiming for close to 100 % automation.

4 temperature zones incl. freezer area

Maximum output 7,820 orders per day

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOur e-commerce solution from KNAPP allows us to be less reliant on the workforce and our throughput is much higher than before. We complete orders much faster, much more accurately, and we can deal with a bigger assortment of items than in a regular store.

Sharon Galatziano

Head of CFC Operation

Shufersal Online

Curious about logistics automation?

Get in touch with our experts today.

Benefits of the automation solution

One system for all temperature ranges

Flexibility to adapt to market demands

Exact sequencing and route planning

Automation is profitable

Higher throughput thanks to robotics

Customer satisfaction and order quality

A glimpse into the solution

Goods-in and decanting

After the groceries have been delivered to the CFC, the Shufersal Online employees working at the 30 decanting stations across the different temperature zones repack them into storage containers. Depending on the inventory turnover rate of the goods, our high-performance Streamline conveyor system conveys the containers to the Evo Shuttle for storage or to the picking stations for further processing.

Storage and order fulfillment

The order containers are opened and any waste is removed before they are conveyed to the buffer. Then they are transported to one of the 4 autobagging machines. The autobagging machine then places 1–2 paper bags into the containers and opens them using its suction cups automatically.

Sequencing for shipping

First, the order containers are sequenced according to the delivery routes and sorted according to the order of delivery. Then, the orders are stacked by our automatic stacking machines and delivered to customers’ homes directly.

Curious about logistics automation?

Get in touch with our experts today.

Our innovations at Shufersal

Pick-it-Easy Robot

Our robot handles the entire range of products fully automatically. The robot uses its specially designed grippers to precisely and carefully place delicate items in the paper bag. Combined with vision systems, the Pick-it-Easy Robot is able to securely determine the grip point and fill the shopping bag perfectly.

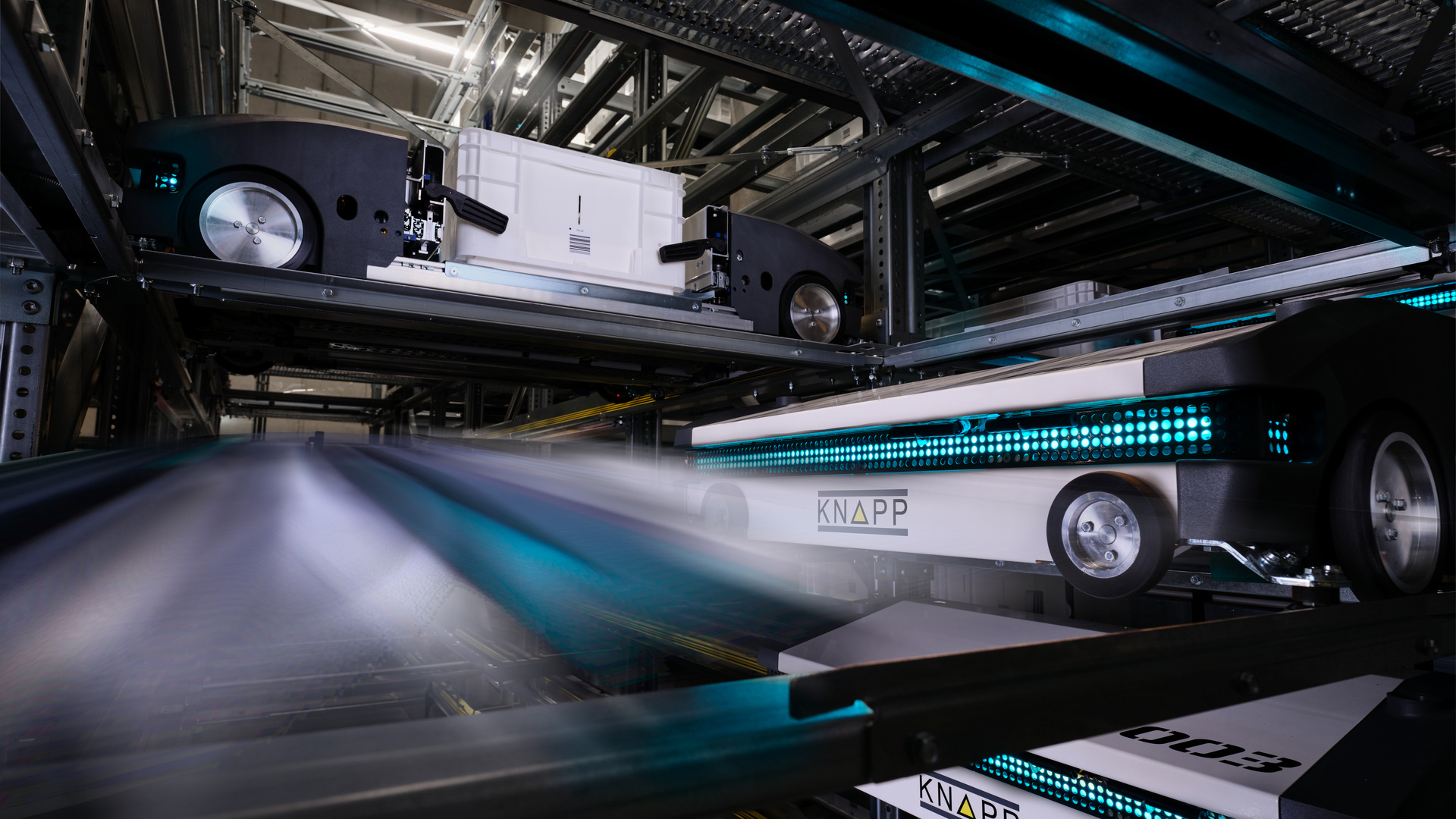

Evo Shuttle for frozen foods

The high-grade construction of the Evo Shuttle means it can handle all temperature zones, ensuring smooth processes in the CFC, from decanting and picking all the way to shipping. The freezer blocks for the order containers can be stored in the shuttle system, which also buffers orders whenever required.

Fully automatic bagging

Fully automatic bagging machines place 2 paper grocery bags into each order container. They then open the bags and fold back the top rim. The order containers with the opened bags are then conveyed to the picking stations, where the employees and robots can fill the bags with items easily.

More proactive and preventive thanks to all-round service

Our Remote Control Center (RCC) is an all-encompassing service solution for ongoing warehouse operation. For Shufersal Online, our Service Desk employees are always on top of things, keeping an overview of all logistical and technical processes as well as software and hardware around the clock. By identifying critical problems early on, any disruptions to operations are rapidly eradicated.

Orders per day

m² Warehouse size

Items per order

Stock Keeping Units (SKUs)

Software and digital services as key enablers

From warehouse management to warehouse control, machine control and intelligent tools for data analysis, Shufersal Online opted for the whole range of digital solutions and services provided by KNAPP.

The scalability of our solution is unique. We’re talking about a huge center that serves thousands of customers every day. This is so unique and complex.

Zvika Baida

Former CEO

Shufersal Online