Our Autonomous Mobile Robots (AMR) for Container Transport

Production companies in industry are facing many challenges such as a shortage of qualified personnel, constantly changing environmental and market situations and fluctuations in performance. Change is the only constant. The challenges for logistics are also growing – existing systems need to be adapted faster than ever. With the Open Shuttles – our autonomous mobile robots (AMR) for container transport – you can master these challenges, reduce costs and increase efficiency at the same time.

Our Open Shuttles allow you to jumpstart your automation endeavors, helping you overcome the following challenges:

- Seasonal peaks and fluctuations in performance

- Ever-changing processes and the required adaptions in your warehouse and production facility

- Handling different load carriers

- Lack of space and high levels of traffic inside the warehouse

Looking for flexible AMRs for container transport?

We are here to help!

Our selection of AMR robots for container transport

Our Open Shuttles are the ideal solution for transporting containers, cartons and trays around your warehouse. Have a look at our scope of models; you will most certainly find the right one for you:

Open Shuttle 50

AMR for transporting up to two containers

Payload of up to 120 kg (265 lb)

Max. dimensions of load: 600 x 400 mm (23.62 x 15.75 in)

Open Shuttle 100

AMR for transporting up to two containers

Payload of up to 120 kg (265 lb)

Max. dimensions of load: 900 x 650 mm (35.43 x 25.59 in)

Check out our high-tech AMRs for container transport:

Our AMRs feel at home in a number of settings

Open Shuttles are highly versatile and the AMR fleet can be installed without any structural modifications, making Open Shuttles an ideal solution for retrofitting existing automated or manual systems with cutting-edge robotics

What the AMRs for container transport can do

- Transport various different load carriers within the warehouse

- Supply work stations and production lines

- Support the picking process

- Connect to automatic storage systems, such as our Evo Shuttle and InduStore

- Complement an existing pallet conveyor system

- Supply kanban racks and flow racks

- Carry out special and express transport tasks

Our Open Shuttles open up novel opportunities for interconnected transport in the warehouse. They are flexible and can be used in a number of settings, making them the perfect solution for handling peak periods.

Advantages of our AMR robots for container transport

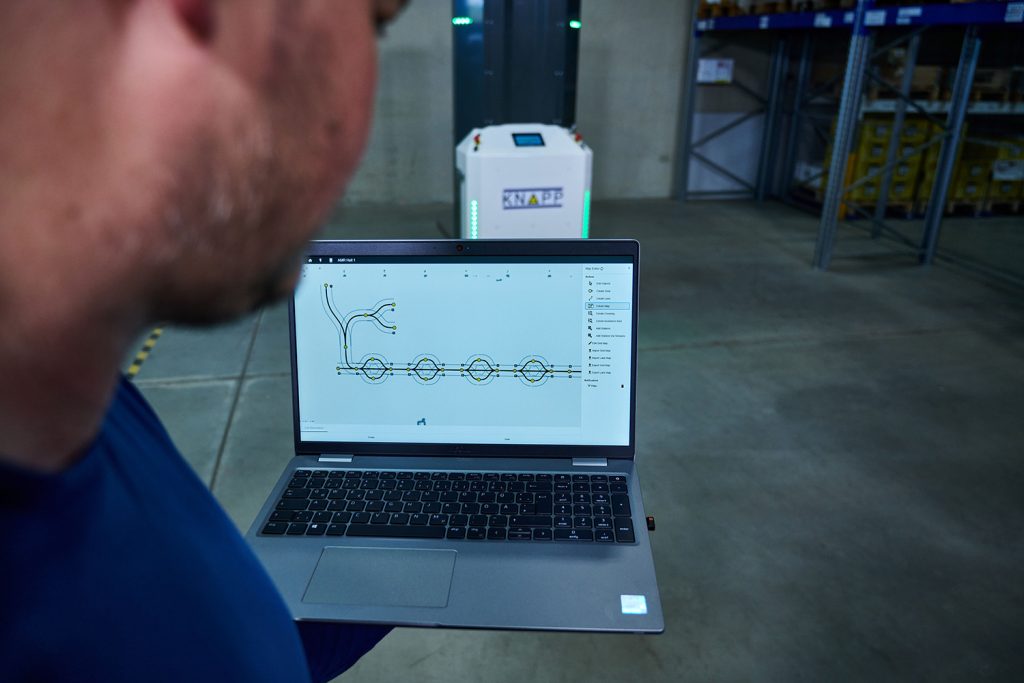

Easy to configure

Simple simulation and control of the layout, processes and fleet; changes can be made independently

Mixed fleets

Flexible interconnection of all warehouse areas with different warehouse vehicles in one system

Easy to integrate, quick startup

Works well with existing systems, no construction needed; quick and easy startup

Intelligent resource management

Smart path planning and intelligent coordination of orders and transport resources

Cost-efficient system

Increased efficiency thanks to 24/7 availability and consistent performance

Ready for immediate use in all industries

Autonomous, robust, deterministic navigation

Maximum safety

3D obstacle detection, blue light and signal lights for more safety in the warehouse, CE-certified

Global service network and a reliable partner

KNAPP as a reliable partner with global customer service

150+ successfully implemented customer projects

How do KNAPP’s autonomous mobile robots work?

Find out more about our intelligent Fleet Management Software!

Open Shuttles + intelligent software

= the perfect solution for production machine supply at Digmesa

When the locations of the subsidiaries Digmesa Polyform and Digmesa AG were combined, the production processes had to be restructured and production moved to a new hall. As part of this relocation project, they wanted to automate the transport processes supplying the assembly machines. An Open Shuttle system was installed and implemented within just four months. The autonomous mobile robot now brings empty containers to the injection molding machines and transports the finished pieces to a flow rack, which serves as a buffer area. The robot automatically transfers the full container to the flow rack according to the first-in first-out principle. The containers are equipped with an RFID tag, ensuring continuous traceability of the goods.

The flexibility that we gain by using this system is incredibly valuable. We didn’t have to install anything for the Open Shuttle in production. All it needs is the general travel paths and nothing else.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information