Selecting the right warehouse management system is crucial for your project’s success, whether that system is Blue Yonder, Manhattan Associates WMS or SAP® Extended Warehouse Management, better known as SAP® EWM. However, the software itself isn’t the only factor. Choosing the right implementation partner is also key. With more than 120 successfully implemented SAP® EWM projects, we at KNAPP have become one of the world’s leading SAP implementation partners. Read our blog post to find out the top 4 reasons why so many of our customers have chosen SAP® EWM as their warehouse management system – with us as their trusted implementation partner.

SAP® EWM by KNAPP:

A powerful WMS and WCS solution

One fundamental question for the world of software is: Best of breed or best of suite? Best of breed means finding the ideal software solution for each process and connecting them through interfaces, while best of suite describes an approach in which a multitude of processes are covered by a single technological supplier. An all-in-one solution with many functions, following the best-of-suite approach, handles all the various processes, resulting in simpler interfaces and a more homogenous technical basis.

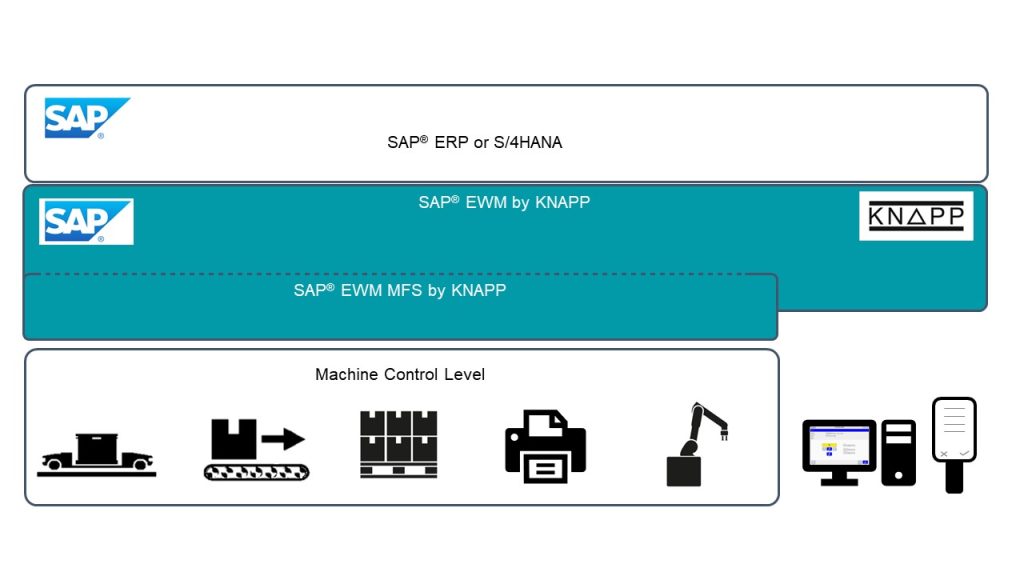

However, software solutions for logistics are not limited to one or the other. SAP® EWM combines the advantages of both approaches for all businesses using an SAP® IT strategy with SAP® ERP or S/4HANA. This logistics software covers all functions on all software levels using SAP® end-to-end solutions – from WMS to machine control. And these functions can be activated as needed, just like with a best-of-breed solution. SAP® EWM also scores because of the versatile options it offers for layout and process-oriented sequential control. In other words, you can customize the system yourself to accommodate new and changed business processes.

What’s important is adaptability. Though the standard version of SAP® EWM is a comprehensive WMS and WCS solution, standard processes are not always sufficient for representing all logistics processes completely; there are always processes unique to a sector or unique to the individual customer. That’s where SAP® EWM by KNAPP comes into play.

1) Automation technology for industry requirements in SAP® EWM by KNAPP with MFS

Along with comprehensive SAP® expertise, logistics know-how in WCS and WMS is key for the successful implementation of SAP® EWM. SAP® EWM by KNAPP combines our experience as an integrator for over 3,000 WMS/WCS projects including automation with the industry expertise of the entire KNAPP group.

Thanks to the best-of-breed approach, the standard version of SAP® EWM is a flexible, scalable WMS that can handle all the challenges of the system’s automation. One decisive factor for the software’s success is the integrated WCS layer, SAP® EWM MFS (material flow system). It connects directly to the PLC, reducing interfaces and enabling the control and integration of common automation technology – regardless of the supplier. All this makes for transparent and seamless end-to-end process control in an SAP® landscape.

Our very own SAP® EWM Building Blocks come into play for more complex automation solutions, such as the OSR Shuttle system, the Central Belt System or innovative vision technologies by KNAPP. This means the solution is an end-to-end SAP® solution that directly integrates and controls subordinate systems without the need for middleware. These tried and tested Building Blocks are completely based on SAP® code and close the gap between SAP® EWM standards and the individual warehouse’s specific requirements. They go beyond connecting different automation technologies and connect specific business processes as well – for example, by optimizing order start in the pharma sector and adapting it to wave planning.

Combined with the standard version of SAP® EWM, the Building Blocks form the basis of our model company in the healthcare sector. Since over 80 % of the warehouse processes in a given industry are identical, we provide a basic framework for processes and then work together with our customers to define the needed extras. A basic SAP® EWM by KNAPP solution is ready very quickly, with crucial core processes such as goods-in, putaway, picking and shipping ready to go. This allows the customer’s key users to start using the software early on, saving time and costs while minimizing risks.

Implementation options with SAP® EWM by KNAPP as a WMS and/or WCS at one or more locations:

SAP® EWM with MFS is a comprehensive WMS/WCS solution

SAP® EWM Healthcare Model Company is a complete WMS/WCS solution, with expansions to handle the special requirements of the healthcare sector

SAP® EWM MFS can also be implemented as a pure WCS system if SAP® EWM was originally implemented as just the WMS

KNAPP Building Blocks for SAP® EWM are used to integrate KNAPP subsystems

"We believe that in opting for SAP® EWM by KNAPP, we have chosen an incredibly stable warehouse management system, one that is well-established on the market and that will fulfill our complex requirements. What’s more, the added benefit of being able to assign all the installations we tendered to a single supplier was a significant plus."

Lukas Röbl, Head of Process Management and<br> Project Manager for SAP® EWM at Avosano AG

2) Almost the real thing: Automated end-to-end tests in SAP® EWM with a digital twin

When we implement SAP® EWM, you benefit from both SAP® and KNAPP. At KNAPP, we do more than just SAP® consulting. In addition to customizing and developing the EWM, we take on other important aspects that are key to successful implementation, including end-to-end planning of the test phases and using a digital twin for the subordinate systems.

In general, the material handling equipment to be integrated in an SAP® EWM automation project is only available for tests to a limited extent. Additionally, operation continues as usual during retrofit projects, while SAP® is implemented for greenfield projects as the sub-installations are being set up. In these cases, the automation isn’t available until a very late stage of the project.

So how can you make sure that the systems will function as smoothly as possible and without any errors? The answer is by using a digital twin for automated end-to-end tests. Digital twins allow you to emulate interfaces between SAP® EWM and the subsystems and to simulate warehouse processes as realistically as possible. Business processes can be tested end-to-end on the automation technology without the need for physical access to the system and mass tests can be carried out to check that SAP® EWM is working correctly. These tests help verify that the MHE interfaces were implemented correctly while under time pressure before the go-live.

3) Project work with SAP® EWM by KNAPP: Teamwork, with learning as key

After the go-live, the SAP® EWM source code is made available to the customer so they can continue to maintain and develop the solution themselves, provided they have the necessary knowledge and resources in-house. In order to build up the foundation for future development, we at KNAPP – if desired – can include our customer’s future SAP® EWM users in clearly defined areas of responsibility from the very start of the project, allowing future SAP® users to gain valuable know-how early on.

The ideal in-house SAP® EWM module managers are nominated from the IT department and already have prior experience with SAP®. They’ll learn in a joint team approach with the KNAPP implementation team through on-the-job training, which is complemented by workshops and classes. Led by KNAPP, the employees work on tasks such as customizing, development, testing and documentation. After the project is completed, they’ll be able to create specifications documents and functional specifications, train other key users, and customize, document, test and start up the software.

4) After the go-live: 24/7 SAP® EWM Service Desk

Regardless of the approach you take, our Service Desk is there to offer ongoing 24/7 support for SAP® EWM whenever you need an extra hand. Our Service Desk is available round the clock to ensure smooth operations at all times. Thanks to a comprehensive analysis of the warehouse processes and systems, our experts can cater to the individual requirements of every system. This includes detecting and correcting recurring errors as well as optimizing system performance.

The Service Desk, available 24/7, offers different support models ranging from complete hotline service to hybrid models offering support for defined times or for specific processes. In addition to continuous support, on-demand services are also available to provide targeted support for inventory, configuring hardware, maintaining master data and system cleanup. These comprehensive services contribute to the long-term upkeep of the efficiency and reliability of the SAP® EWM systems.

"The transition of our warehouse into 24/7 support was done in phases so the KNAPP Service Desk team could become familiar with our SAP® EWM with all its features. We are completely satisfied with the support."

Gerald Goldgruber, Strategic Head, Process Management and SAP, Frutura Obst & Gemüse Kompetenzzentrum GmbH

Is SAP® EWM as warehouse management system right for your warehouse?

Are you interested in finding just the right SAP® EWM solution for your company? Or perhaps you recognize the need to optimize your existing SAP® EWM system? Contact us to find out how we can work together to take your logistics processes to the next level.