Hospital – just the word is enough to give people the shivers. Let’s call it healthcare facility instead, because that’s what it’s about: becoming healthy again. Numerous processes in a healthcare facility need to run like clockwork, especially those involved in ensuring optimal care for patients. In addition to comprehensive first care, counselling and providing care in the facility, serving patients the correct food punctually and providing the right surgical instruments are also very important. Precisely these so-called tertiary healthcare services hold great potential for process optimization. What exactly does this mean? An intelligent logistics solution forms the physical link between the disciplines. Simultaneously, this generates added value for patients. Come along as we take a look into the future of healthcare logistics at the KNAPP Versorgungscampus.

High requirements are shaping the healthcare sector

The health sector is on the move. While the length of stays in healthcare facilities is sinking, the number of patients is on the rise. As a consequence, the demand for personnel is increasing along with cost pressure. The highest levels of hygiene and requirements – such as end-to-end traceability – also pose new challenges for the healthcare sector. That’s why caring for patients individually and economically is now more important than ever. Various questions arise from these requirements such as:

- How can the increasing number of patients be cared for and the increasing number of healthcare and nursing facilities be efficiently supplied?

- How can the legal requirements such as continuous traceability be best implemented?

- How can we ensure the highest level of hygiene?

- How should we design the tertiary supply processes so that they are profitable and at the same time create the maximum added value for patients?

Logistics shifts the focus to the patients’ well-being

Working with leading experts from the healthcare sector, we have developed the KNAPP Versorgungscampus, a new solution for tertiary healthcare services. Our colleague Johannes Kompek was part of the interdisciplinary project team and explains what the idea of the KNAPP Versorgungscampus is all about:

“This approach focusses on re-designing the tertiary supply processes with the motto: Professionalization through centralization. Medicines, ward supplies, food, sterile surgical instruments and much more are needed in one location – the respective healthcare facility. So, why not bundle the various logistical processes of the supply chain and supply healthcare facilities centrally from one location? This is precisely what we achieve with the KNAPP Versorgungscampus, raising tertiary supply to an all new level. More importantly, the focus remains on the patients, their safety and their individual needs.“

Johannes Kompek, Healthcare Solutions, KNAPP AG

Simple. Flexible. Completely traceable.

Simple, flexible and completely traceable – these qualities are the three pillars supporting the KNAPP Versorgungscampus. By handling tertiary supply from a central location, the processes are streamlined and simplified.

The heart of the solution is an automatic storage system, the OSR Shuttle™ Evo, where all the goods are stored space-effectively in one location, allowing access at all times. The OSR Shuttle™ Evo supplies the various other areas in the KNAPP Versorgungscampus with the necessary goods, be it a commercial kitchen, the sterilization area or work areas where medications are dispensed.

ProServ sets new standards in patient care

ProServ, a German full service provider and supplier in the healthcare sector, has already made the KNAPP Versorgungscampus a reality. Since 2018, ProServ has been supplying its hospital customers with meals for patients directly from the KNAPP Versorgungscampus: 6,000 trays are provided by the facility on a daily basis. Furthermore, 10 hospitals have their surgical instruments processed at the healthcare logistics centre.

Hans. J. Peglow, initiator of ProServ and former managing director of a hospital, explained the significance and advantages of such a healthcare logistics centre for the future of healthcare:

“Hospitals focus on cost-effective services providing quality assurance. A hospital can only survive if the assured quality standards are accompanied by optimal cost structures. This requires optimal processes, not only in the work with the patient, but really in all the supply processes. The supply processes require motivated employees to work in a highly professional intralogistics environment. The healthcare logistics centre today is still in its infancy; however, with a partnership between an outstanding logistician like KNAPP and an expert in clinical structures and processes like ProServ, it offers outstanding competitive prospects. This is the only combination that will develop first-class and optimal operations.“

Hans. J. Peglow, Initiator ofProServ

How the KNAPP Versorgungscampus works

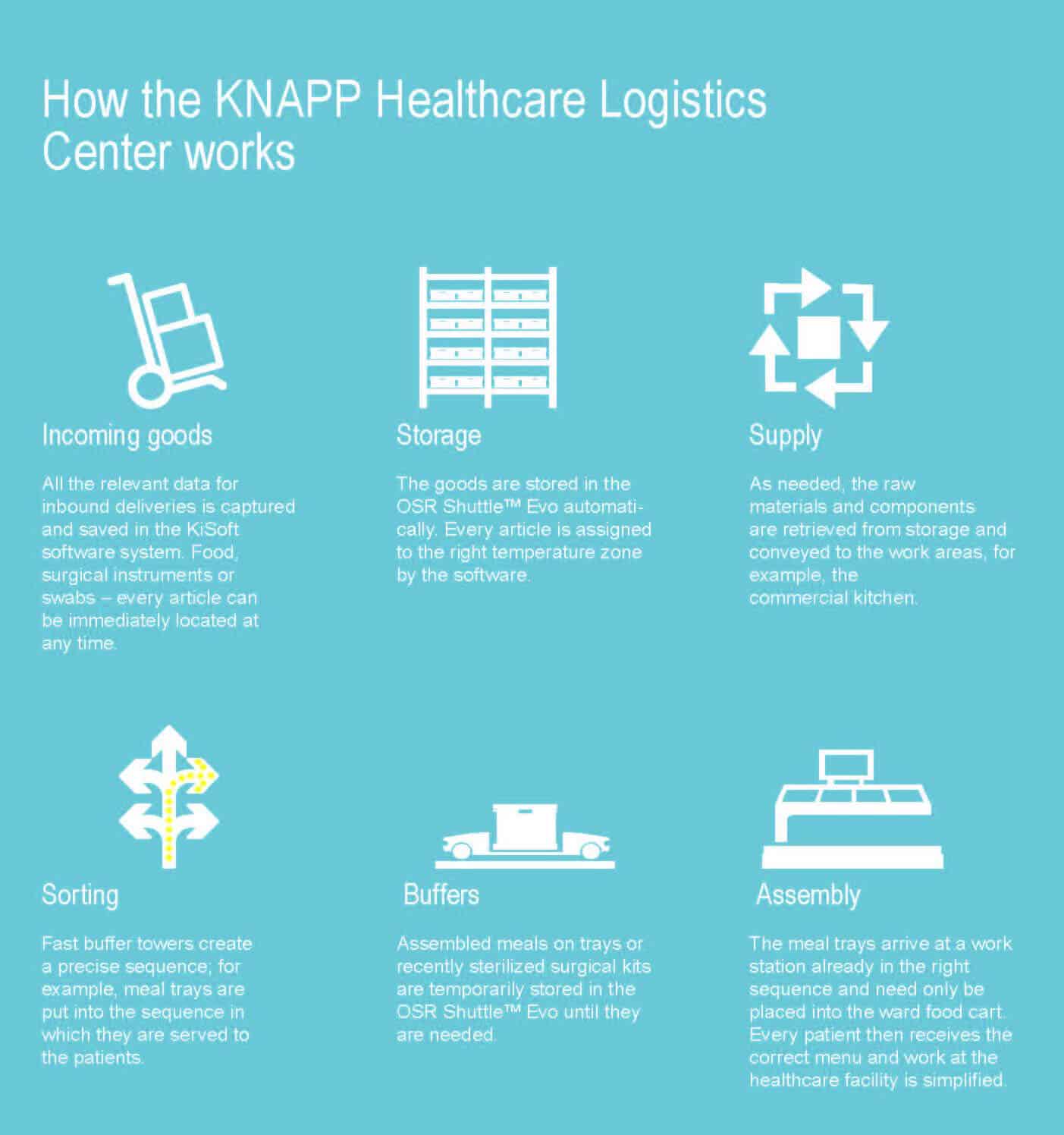

- Incoming goods: All goods are recorded and can be immediately accessed using the intelligent software KiSoft.

- Storage in the central warehouse system Every article is assigned to the right temperature zone by the software.

- Supply: As needed, the raw materials and components are retrieved from storage and conveyed to the work areas, for example, the commercial kitchen.

- Buffering: Assembled meals on trays or recently sterilized surgical kits are stored in the OSR Shuttle™ Evo until they are needed.

- Sorting and assembling: Fast buffer towers create a precise sequence for delivery. Every patient receives the correct menu and work at the healthcare facility is simplified.

Further reading recommendations

The KNAPP subsidiaries Apostore and adcommander are merging the online world and real pharmacies.

An error-free supply chain provides more safety for patients. With the right mix of know-how, smart technologies and software, KNAPP can fulfil all the requirements related to serialization and lot tracking.

New technologies are changing the workplace of people in logistics and production. Smart workers is what we call this new generation of workers. In the following blogpost, a smart worker takes us on a trip through tomorrow’s world of work.

Additional Information

Do you have any questions on the KNAPP Versorgungscampus? Write to us at blog@knapp.com.