Whether it’s the bagel for your breakfast, the ingredients for your weekend meals or cleaning utensils: We can find all the things we need every day at our neighborhood supermarkets. What do we always take with us to run errands? A shopping list, of course, either on a slip of paper or a mobile device. What is important to us as we walk through the aisles? That we can actually find all the things we need.

How the food retailer keeps both customers and employees happy

The ultimate objective of any food retailer is to satisfy customers and employees. No matter which item is selling like hotcakes or how much demand changes during the course of a year: The consumer expects to find that the groceries they want on the shelves, fresh and in the best quality. Employees can enjoy their work when filling the shelves is easy and doesn’t require them to traipse through the store.

Food retailers can guarantee the best possible service to their customers thanks to ultramodern automation technology. To do so, all items must be available in the stores at the right time and in the right quantity.

The logistics system in the background must provide the right mix of:

- Flexibility

- Productivity

- Scalability

Our concepts use intelligent technologies that provide optimal sequencing.

In food retail it is critical that employees are able to fill the shelves in as little time as possible. The stores supplied vary in size and layout, as well as in the items stocked. This means that for each store, orders are picked individually and differ widely. When automatically processing groceries, criteria such as shop-friendly delivery, customer-specific item sequences and packing parameters play an important role. The solutions that involve innovative technology and intelligent software allow optimal sequencing for compiling orders and packing them in a shop-friendly manner. This results in time and cost savings in the stores.

The many advantages of our solutions for brick and mortar retail:

- Ideal adaptation of the solution to the customer requirements

- Efficient store delivery with semi- or fully-automatic solutions

- Economical solutions

- Automation solutions that are effective over the long run

- Coverage of the complete range in food retail

- Efficient storage and delivery

- Ergonomic picking and reduced physical strain

- Optimal support in B2B distribution

- Counteraction for labor shortages

- Precise sequencing

- Future extensions and adaptations of the logistics processes possible

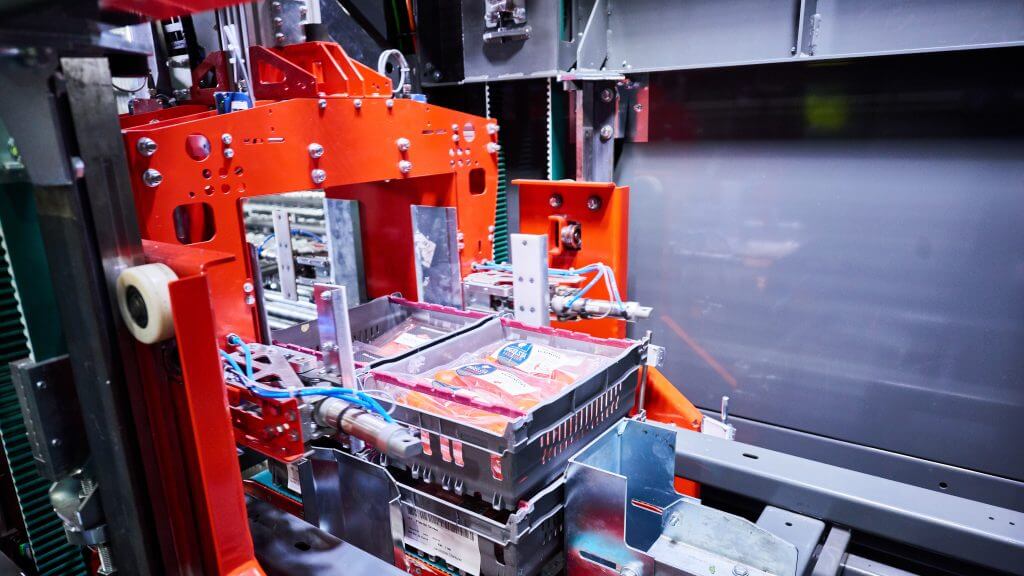

Fully-automated standard tray picking (FAST Picking) for fully-automatic picking of fresh foods

Fresh produce deliveries to stores of meats, deli products, dairy products, fruits and vegetables come in heavy standard handling units, which might include foldable crates from pool crate suppliers or cartons. The processing of handling units represents an enormous physical strain for employees due to their heavy weight.

With our fully-automatic FAST Picking solution, different standard handling units for orders are arranged quickly and efficiently. This space-effective solution allows error-free and economic processing of an extensive range of groceries. Switching to a fully-automatic processing of these standard handling units reduces the physical strain on employees to a minimum.

How FAST Picking works:

FAST Picking uses full automation to solve numerous challenges in logistics for the food retail sector

Challenges

Solutions

Full automation at Dagab guarantees maximum freshness for food retail in Sweden

Dagab Inköp & Logistik AB is a Swedish logistics company specialized in the storage and delivery of foods. As subsidiary of Axfood, Dagab is responsible for the logistics processes and the supply to stores. Up to 600 stores and small distribution centers are supplied with fresh groceries from the main DC in Jönköping. For the best in economical and error-free processes at the Jönköping site, Dagab opted for our FAST Picking solution. This fully-automatic solution processes an extensive range of groceries such as dairy products, meat products, fruits and vegetables economically and without error. This means efficient delivery to the stores on time.

Solution highlights

Fully-automatic depalletizing robots and destackers for gentle and efficient grocery storage.

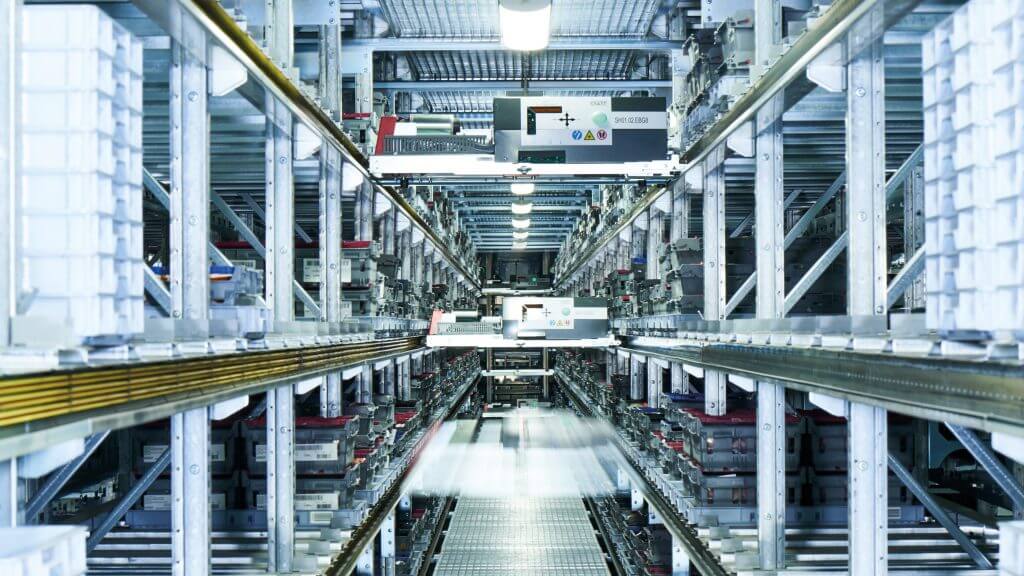

OSR Shuttle™ with 7,200 locations for storage, sequencing and picking of orders.

Fully-automatic stackers and palletizing robots for building shop-friendly store pallets.

Ergonomic Pick-it-Easy work stations for manual depalletizing of mixed pallets and palletizing of small orders and mixed pallets with different recipients.

Experience Dagab’s full automation

Further reading recommendations

In challenging times, a reliable and competent partner who controls and enforces the logistics processes in the background at the required speed is essential. Someone who supplies large supermarket chains, but also small and online retailers with high-quality groceries.

How can articles arrive at the customer undamaged? What can software do to reduce transport costs? How do the stock clerks in the stores benefit? What does KNAPP’s software KiSoft Pack Master have in common with Tetris? Here, the answers to these questions.

Additional Information

For more information on our FAST Picking solutions, please write to blog@knapp.com.