Intelligent Master Data Management for Automation:

KiSoft Genomix in action at SPAR

Automation solutions only work with high-quality master data. Only with the right attributes, the technologies – such as robots – know how to process or handle items. This increases the efficiency and performance in an automated warehouse environment and reduces the error rate. What’s the magic formula? The more attributes you collect and the higher their quality, the better the automation solution will work. Our customer SPAR Ebergassing already works with KiSoft Genomix and benefits from the added value it generates along the entire process chain.

How SPAR benefits from KiSoft Genomix

SPAR, one of our customers active in the food retail sector already uses KiSoft Genomix and benefits from the added value added our system generates. SPAR has been on board as a pilot customer and has tested our software solution. Patrick Hörmann, Warhousing and Goods Flow Manager at SPAR Ebergassing is enthusiastic:

“Before implementing KiSoft Genomix, recording our master data was quite laborious. We had to look at the item, measure its dimensions, enter all the data and check twice whether everything was correct. This procedure was not really efficient. Now, we put the item on MultiScan and KiSoft Genomix takes care of the rest. We save approximately 90 % of the work that used to go into master data management.”

KiSoft Genomix minimizes human errors

The goal of our long-standing partner SPAR Ebergassing was to exclude subjective assessments in master data recording, which can be quite problematic.

The classification of items starts with their delivery. When five employees look at the same item, everyone sees something different. They see the carton, the manufacturer and so on. KiSoft Genomix excludes this subjectivity.

Do you also want high-quality master data?

Get in touch with our experts today.

Automated all-encompassing process for optimal precision

KiSoft Genomix already comes in handy during the goods-in procedure. Our MultiScan fully automatically captures the dimensions, weight and volume of the items and integrates the digitized data into the system. Our KiSoft Genomix app adds further attributes to the information and data. It intuitively guides the employee through a simple questionnaire, thereby recording all necessary parameters from the single piece to pack unit to logistical unit. KiSoft Genomix also registers the entire item hierarchy. “The classification of items starts with their delivery. When five employees look at the same item, everyone sees something different. They see the carton, the manufacturer and so on. KiSoft Genomix excludes this subjectivity,” enthuses Patrick Hörmann.

MultiScan captures the attributes of items within seconds.

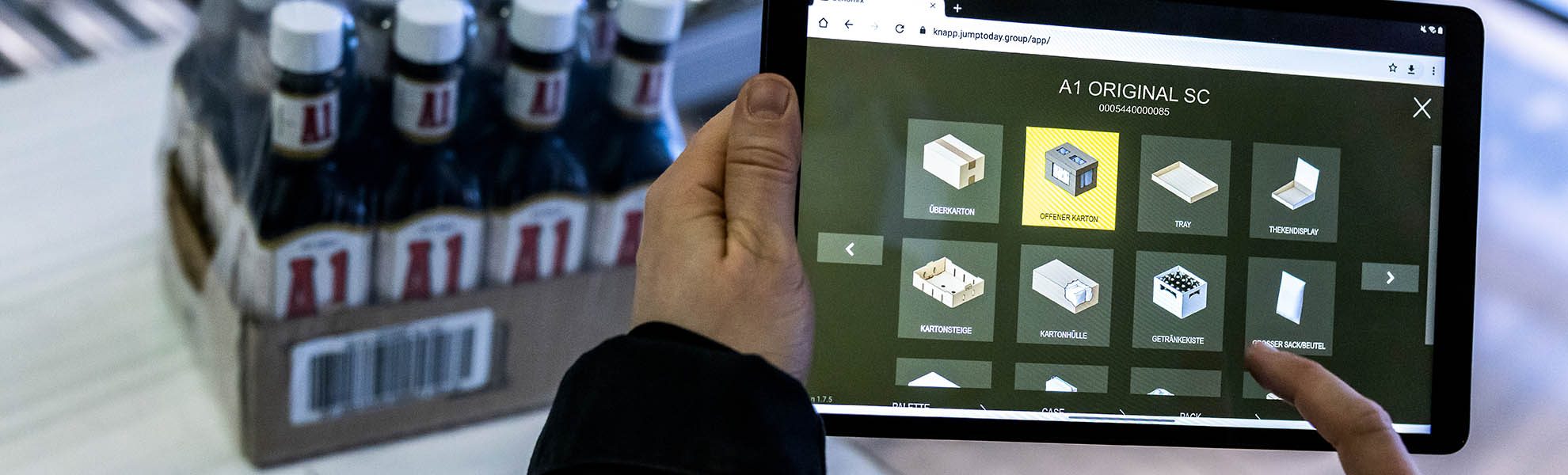

The KiSoft Genomix app allows easy and intuitive recoding of item attributes.

The cutting-edge vision system ivii iriis carries out an additional quality check.

We have a very good partnership with KNAPP, the are very open-minded. Of course, this bond took time to form. We’ve been partners for five years now and our collaboration is better than ever before. We are very glad to have KNAPP as a partner, especially when it comes to innovations like these.

Cutting-edge vision system checks quality

Our ivii iriis is also an important part of the solution and carries out a quality check. It determines whether the attributes recorded in the system matches the actual data of the item. All data is made available digitally on a server for use in subsequent processes. This way, the data is available for all the calculations in an automated warehouse environment. Self-learning algorithms continuously improve the quality of the data.

KiSoft Genomix’s scope of application

Our system can be used across sectors including retail and food retail and across all sales channels, such as omnichannel, e-commerce and store delivery. Furthermore, KiSoft Genomix is independent of the solutions provider and the implemented software. Another benefit is the availability of data across warehouses. The automation data managed by KiSoft Genomix can also be used for other distribution centers.

Did you know…?

… that around 70 percent of the currently used attributes are inadequate?

Only 30 percent of the master data in an automated warehouse have the required quality.

… that numerous item attributes are needed for efficient automated warehouse logistics?

Around 200 attributes are necessary to guarantee secure processes. This is only possible with comprehensive, automated master data management.

…that automation data determines the behavior of robots, for instance?

When robots know all attributes across all hierarchies, they have an in-depth understanding of how to handle every item. The information helps the robot grab items correctly, reducing the risk of damage, the error rate and downtimes of robots.

… that the quality of master data suffers when it’s recorded manually?

Collecting data manually involves a lot of costs and effort. In addition, errors occur due to subjective judgments.

… that the characteristics of items often change while they are being transported?

To detect these changes, an end-to-end system is needed that also records the deviations. This is the only way to ensure ideal item handling.