The increasing complexities in production and in internal logistics are making it more challenging than ever for companies. An intelligent software solution is just the enabler needed for perfection in production supply. More and more companies are relying on a uniform SAP IT system in all areas of their businesses. Software expert KNAPP has been an SAP partner, offering solutions from two product lines, SAP® EWM by KNAPP and KiSoft.

Software solutions for production supply

Manufacturing is on the verge of change. Mass customization and made-to-order are replacing classic serial production more and more. This means complex processes and structures. Production intralogistics are gaining ground and opening new potential for greater efficiency. In this area, competitive advantage can be gained using a software solution that covers all the processes optimally. This is often not the case with standard solutions. On the other hand, the best of breed approaches (where each process is supported by its own suitable software and integrated with the overall solution through interfaces) – because integration is difficult – often do not represent a truly optimal solution. SAP® offers the advantages of both approaches. This is a standardized software with IT modules that can be individually and transparently adapted. For example, there is a production supply module in EWM (Extended Warehouse Management) that can manage the storage and material supply in connection with the manufacturing and process orders.

In our experience, about 70-80 percent of production companies are using SAP as an ERP system.

Software expert KNAPP

The right solution for each and every area! From warehouse management to the control of optical sensors. Our intelligent software solutions provide a solution for every area. Depending on what’s needed, we cover the processes with our product lines KiSoft and SAP® EWM by KNAPP, thereby securing the performance, productivity and transparency of the entire supply chain. We have a goal: finding the optimal solution for each company. In the industrial sector, both software solutions are common and have been implemented many times over. As a general contractor, we implement over-all solutions as well as stand-alone solutions.

Regardless of the software structure and philosophy of the company, it is important to us to always find the best solution for the customer.

SAP partner since 2012

The SAP experts are in-house at subsidiary KNAPP IT Solutions. The SAP® EWM by KNAPP is the right solution for any company that wants to implement an SAP IT strategy and is looking for an outstanding logistics solution. Customers have the possibility to do programming and make adjustments themselves, providing a comprehensive SAP® solution for a lesser investment while having access to the expertise of the KNAPP group for the intralogistics. Since 80 percent of all warehouse processes in an industry are identical, proven solutions are preconfigured. The focus of a project then is to develop and implement the specific processes. This minimizes the implementation time as well as the project risk.

The SAP experts are in-house at subsidiary KNAPP IT Solutions. The SAP® EWM by KNAPP is the right solution for any company that wants to implement an SAP IT strategy and is looking for an outstanding logistics solution. Customers have the possibility to do programming and make adjustments themselves, providing a comprehensive SAP® solution for a lesser investment while having access to the expertise of the KNAPP group for the intralogistics. Since 80 percent of all warehouse processes in an industry are identical, proven solutions are preconfigured. The focus of a project then is to develop and implement the specific processes. This minimizes the implementation time as well as the project risk.

KNAPP has been an SAP partner for more than 10 years. With more than 100 EWM and more than 3,000 WMS/WCS installations worldwide, the team is growing, as are the projects. In the meanwhile, more than 100 SAP® EWM experts and a hotline providing 24/7 support are available.

With SAP® EWM by KNAPP, we offer our customers the best logistics solutions, fully integrated on an SAP IT platform. These solutions are based around our philosophy ‘making complexity simple’, our many years of experience in warehouse automation and the successful approach to project management we have developed.

SAP® EWM by KNAPP and KiSoft: two worlds of software, one goal

The goal is to find the perfect solution. But what are the differences between SAP® EWM by KNAPP and KiSoft, and how would you describe the system landscape?

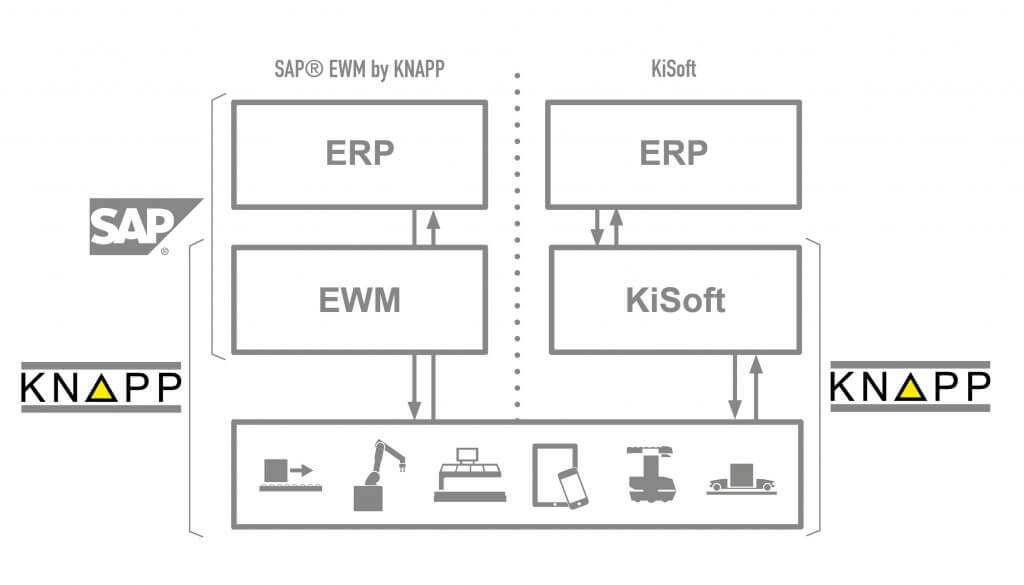

An Enterprise Resource Planning (ERP) system forms the higher-level system, which can come from SAP but also from other providers. With the SAP® EWM by KNAPP solution, the ERP system is in direct contact with the machine control system through the EWM. With the KiSoft solution, the ERP system is connected through an interface to KiSoft, and KiSoft processes the information, which is transmitted to and from the machine control system.

What is the best solution for your company?

This is a question that has to be answered together. Here is a quick overview of the areas of application and the different advantages provided by each solution.

SAP® EWM by KNAPP

SAP® EWM by KNAPP is a solution for every degree of automation and transparent, efficient supply chain execution. The integrated modules, for example, can support supply and stock management in production supply areas, simulate workloads or generate the staff shift plan. A direct coupling to the control system is achieved with the integrated MFS (Material Flow System).

Scope of application

When it comes to warehouse and production supply solutions, along with SAP® EWM, WMS (Warehouse Management System) and WCS (Warehouse Control System) know-how are important. Thanks to many years of experience in intralogistics, we have the expertise needed to implement software solutions for new projects, warehouse expansions and retrofit projects as well. For retrofits, existing systems are replaced by SAP® EWM.

The benefit

For the supply chain in particular, using SAP® EWM and SAP TM (Transport Management) offers important advantages with respect to flexibility and future-proofing for customers having an SAP IT strategy. All the benefits of the SAP world, such as expert availability, in-house SAP consultants, the source code, etc., come together with KNAPP as solution partner for logistics systems and logistics processes. Furthermore, the subordinate control system can be directly integrated in SAP® EWM without further layers of software. Tried and tested KNAPP building blocks for SAP® EWM such as the easyUse user interface or MHE driver & algorithm provide further benefits for the user.

Best-Practice for SAP® EWM by KNAPP

Voigt Industrie Service AG

For more than 150 years, the VOIGT Group, with its subsidiaries VOIGT AG for wholesale and VOIGT Industrie Service AG for pre-wholesale, has been an established link between the pharmaceutical industry and specialist retailers in Switzerland. Together with the VOIGT Group, we implemented a complete solution for a flexible supply chain, combining the areas of pre-wholesale and wholesale, at a distribution center with a logistics system at the Niederbipp site.

The logistics software SAP® EWM by KNAPP may be invisible to the casual onlooker but, working behind the scenes, it plays a leading role in VOIGT’s new, innovative distribution center. It’s the central control element, the place where all technologies and processes in the warehouse come together. As a warehouse management and material flow control system, SAP® EWM by KNAPP maps all processes from goods registration to goods-out in the RF-guided and automated areas. This includes goods registration including prioritized processing of urgently required goods, specific processes in goods-in that are flexibly tailored to the clients, storage, replenishment control and goods-out. In goods-out, various calculations are made for the handling units, not only to ensure the optimal use of space, but also regarding their transit times by order type and time remaining before shipment.

Watch the case study and video here!

KiSoft

The comprehensive KiSoft features fulfill all requirements in terms of managing and controlling flows of goods and information for the entire life cycle of a system. This is a customized software solution from one supplier, covering processes at all levels, from WMS to WCS to machine control.

Scope of application

KiSoft’s scope of application is identical to that of SAP® EWM by KNAPP. The difference lies in the higher-level Host system. The Host system is not directly connected to the machine control system but connects instead through an interface with KiSoft.

The benefit

The software solution can be customized to the customer’s requirements independent of the Host system. This simple implementation and integration into various ERP systems, in combination with life-cycle support, offers the highest investment security. KiSoft is equipped with easyUse user interfaces at every level, providing modern human-machine communication.

Best-Practice for KiSoft

Terberg Benschop B.V.

Terberg Benschop, manufacturer of special vehicles used in ports, industry and road construction, installed an automatic small-parts warehouse that supplies work stations, Kanban racks and production lines.

To be able to more efficiently process a greater number of orders, the production warehouse, the line supply for vehicle assembly and the global spare parts warehouse were centralized in a new building. An OSR Shuttle™ was installed for the small parts and two Pick-it-Easy work stations were installed in the picking area. KiSoft with Webservices interface to Dynamics AX, the customer’s system, is responsible for warehouse management and control, including the machine control. The special feature of the solution is that it includes three different types of picking at the Pick-it-Easy work stations.

Watch the video here!

Further reading recommendations

What does the smart factory of the future look like? Find out more about our vision for smart manufacturing!

In this challenging situation, how can we support KNAPP customers with proactive service? What advantages do targeted data analyses, service platforms and remote communication provide?

Invisible. Essential. Underestimated. Software. Software – it’s invisible, essential and yet all too often completely underestimated. Though we are mostly unaware of it, software accompanies…

Additional Information

Would you like to learn more about SAP® EWM by KNAPP and KiSoft? At KNAPP, we look forward to discussing ideas and requests with you to create the right solutions. Write to us at blog@knapp.com.