Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) have one task: to transport materials in a warehouse or manufacturing hall from one location to another. But that’s all the two types of automated transport systems have in common as these two systems could not be any more different in design. Read on to learn about:

Advantages at a glance

|

AGV |

AMR |

|

| Navigation |

Line-guided; no artificial intelligence |

Autonomous; uses artificial intelligence |

| Software and control |

Central control system |

Decentral; AMRs communicate with each other |

| Safety |

Stops for obstacles |

Navigates around obstacles |

| Installation |

Requires additional construction (e.g. floor lines and other marks) |

Fast and easy; no landmarks or other navigation aides |

| Startup |

Physical infrastructure needed |

Can be integrated directly into existing physical surroundings and software landscape |

| Flexibility |

Difficult to change/scale |

Fast and easy to change/scale |

| Reliability |

Plannable and consistent transport processes |

Adaptive and autonomous transport processes |

| Maintenance |

Focus on mechanics and physical infrastructure |

Focus on sensors and software; some features can be maintained remotely |

| Costs |

Acquisition costs low; additional construction costs |

Acquisition costs slightly higher; no construction required |

How AGVs evolved into AMRs

For many years, AGVs were the only flexible option for automating internal transport tasks. They came into use in the 1950s and 60s and quickly took over physically demanding, monotonous and repetitive tasks and material flows. As the industry developed and the demand for mass customization grew, so did the demand for more flexibility and scalability in transport systems. Flexibility requires intelligent systems and the first autonomous mobile robots entered the market in the 2010s.

Today’s AMRs use advanced technologies for simultaneous localization and mapping (SLAM). Combined with AI-supported navigation, modern AMRs can flexibly move around in highly dynamic and unstructured environments with great precision. Another milestone in the development of AMRs is sensor fusion whereby the data from lidar sensors, time-of-flight (ToF) technology, 3D cameras and ultrasonic sensors is combined, taking the imaging of surroundings to a whole new level. It also improves both AGV and AMR safety as well as their ability to react to unexpected situations fast and reliably.

So, AGVs and AMRs have been a part of everyday life in logistics for years, but explaining the difference between them remains a challenge. Let’s start by defining both terms before we explore the differences.

What is an AGV?

Automated guided vehicles (AGVs) are driverless vehicles with their own drive unit that move on a specific, defined path. They are steered automatically and can therefore transport goods without an operator. However, AGVs can only drive on a predefined route. They use sensors to navigate as well as marks, inductive loops and nearby reflectors to guide them.

What is an AMR?

Autonomous mobile robots (AMRs) flexibly and dynamically react to changes in their surroundings in real time thanks to digital maps of the warehouse paired with highly sophisticated sensors and AI that allow them to independently detect obstacles and avoid them.

AMRs vs. AGVs

AGVs and AMRs both fulfill the same tasks. Both systems are a quick and easy way to connect different warehouse areas and provide them with materials. However, AGVs and AMRs are equipped differently and have their own pros and cons depending on their areas of use.

We’ve compared the following aspects of the two transport systems:

Navigation

Software and control

Safety

Installation

Startup

Flexibility

Reliability

Maintenance

Scope of application

Costs

Software and control: central vs. decentral

AGVs receive predefined instructions from a central control system. It communicates with the AGVs, plans routes and assigns them to the AGVs. In contrast, AMRs communicate with each other, based on decentralized, peer-to-peer communication, and flexibly adapt their behavior depending on the situation.

AMRs operate with artificial intelligence (AI), which optimizes routes, helps the robots detect objects and people and learn continuously. While AGVs only have limited access to data, AMRs have several options for real-time data analysis, reporting and optimization thanks to intelligent software.

Safety: avoiding obstacles vs. automatic stops

Thanks to their technologies, both AGVs and AMRs are completely safe to use in warehouses. Both systems have safety scanners and are often also equipped with cameras and numerous other sensors.

What makes them different is how each system handles obstacles. AGVs stop when an obstacle blocks their path and waits for the path to be cleared, while AMRs drive around obstacles before finding a new path to their destination thanks to their artificial intelligence.

Installation: during operation vs. construction required

AMRs’ ability to navigate, paired with their intelligent software, mean they place no or only very few demands on their environment. They can be integrated into internal transport processes quickly and without any need for construction or modifications, even during on-going operation. They don’t need much space to perform their transport tasks and can even navigate very narrow passages.

AGVs, however, are a different story. Planning the route network requires a lot of work and additional construction often has to be performed in the building, which means installation can only be done if operation is interrupted.

Startup: significant vs. low effort

Since AGVs need physical infrastructure to navigate, while AMRs move around the warehouse autonomously, there are more things to consider apart from the necessary construction work. Integrating AGVs into the existing infrastructure is rather cumbersome, as routes need to be planned ahead and reflectors and line markings installed.

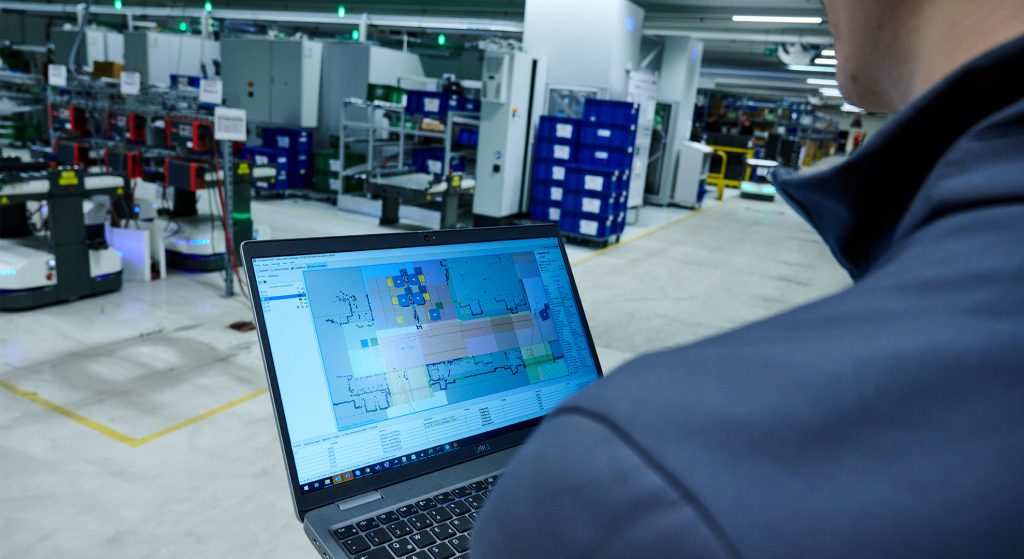

AMRs on the other hand, use software to scan and map their surroundings and their routes can be changed flexibly. Software interfaces allow the AMRs to be integrated into existing infrastructure fast and efficiently and transport processes can be simulated, tested and optimized using a digital twin before the transport system is put into operation.

Find out more in our blog post, “Digital Twins in Logistics”.

Flexibility: scalability vs. fixed system

Thanks to their autonomy, AMRs are much more flexible than AGVs, which travel on fixed paths. The paths and fleet size of AGVs are difficult to change without additional construction and can only be adjusted by the supplier, which means more costs and time spent making adjustments.

AMRs, on the other hand, adapt their routes and processes using intelligent software. Changes to the warehouse layout can be accounted for in minutes using drag and drop. The fleet size can also be changed as required, such as to cover peaks or react to changes in the market.

Reliability: independence vs. plannability

The tasks carried out and paths taken by AGVs are simple and straightforward. Transports are always carried out the same way, travel paths don’t change and the vehicle stops if an obstacle is in the way. So routes must be clear of obstacles at all times. These factors mean that AGVs are very predictable and their actions plannable. They are punctual and highly efficient in performing their transport tasks.

AMRs make dynamic decisions on which route to take based on the given situation. Thanks to autonomous navigation, they avoid obstacles flexibly and plan alternative routes independently. Even though this means their paths are less predictable than those of AGVs, AMRs’ ability to adapt is a huge advantage in ever-changing production and logistics processes.

Maintenance: intelligent software vs. mechanics

Compared to AMRs, the mechanics and sensors of AGVs rely more heavily on external navigation technologies such as magnetic strips, inductive loops and QR codes. These external systems have to be maintained and serviced regularly, as well as mechanical components, which are subject to wear and tear. AGV wheels have to be replaced routinely due to wear and dirt, and checks of motors, lifting elements and shock absorbers should also be carried out on a regular basis. Sensor supports and the basic frame of the vehicles also need to be checked for loose connections, cracks and deformations.

While the mechanics of AMRs need regular maintenance too, it’s the AMRs’ complex sensors that require the most attention and includes updating the software. However, error diagnostics are mainly carried out using software and can also be done remotely. The communication system, state of the battery and laser scanners (lidar) also need to be checked on a regular basis. To ensure reliable AMR operation, cleaning the robots thoroughly – their sensors in particular – and checking all cable connections is of utmost importance.

Applications: flexibility of both systems

Originally, AMRs were used to transport lighter loads, while AGVs transported pallets. Today, their areas of application hardly differ at all. Both automated transport systems perform a variety of internal transport tasks. The most frequent uses include supplying work stations and production lines, supporting the picking process and providing connection to conveyor systems or automated storage systems.

Costs: intelligence vs. price

Which automated transport system is more cost-efficient? At first glance, the acquisition costs of AGVs are often lower than those of AMRs, which are more expensive due to their intelligence and complex sensors. However, once the costs of modifying the warehouse to accommodate the AGVs are taken into account, including the more complicated planning and commissioning, costs are frequently higher.

In addition, startup often requires production to be stopped if the AGVs are not being built into a new system. These interruptions can be costly. AMRs, on the other hand, can be implemented quickly even into existing infrastructure and increase efficiency immediately. Later changes made to an AMR system are also much faster and easier to carry out. Since customer expectations are increasing, requiring today’s manufacturing processes to be more flexible and varied, changes to the existing building are more often included in the calculation to achieve a viable return on investment.

AMRs vs. AGVs – which is the better choice?

Are you now wondering which criteria need to be taken into account when choosing an automated transport system? The following questions are crucial when deciding between AGVs and AMRs:

- Which transport tasks does the system need to perform?

- Does the system need to be changeable and scalable?

- Are goods flows constant or highly dynamic?

If travel paths remain the same, if material flows are constant and if there is a low number of obstacles, AGVs are preferable. They are lower-cost and perform all their tasks precisely and reliably. However, if paths and transport tasks vary, AMRs are definitely the better choice.

And change is a fact of life, especially in today’s market. We’re all struggling with decreasing plannability, the shortage of qualified personnel and resource shortages. As a result, it’s of utmost importance that today’s automated transport systems are fast to integrate and adapt. A modern production environment should not make itself dependent on inflexible technology. In today’s world, AMRs are superior to AGVs in terms of flexibility, scalability, installation time and profitability.

However, planning a complete automation solution is much more than just deciding between AGVs and AMRs. They’re often part of a hybrid solution consisting of a mixture of automated transport systems, manual and automated conveyor systems, state-of-the-art picking systems and mixed traffic. And of course, an automation solution cannot succeed without its key component – intelligent software.

AMR deployment across different sectors

With autonomous mobile robots, companies can take the first step towards automation, especially in the warehouse and to optimize their logistics. AMRs connect different storage and production areas with supply work stations and production lines just in time. Here are some interesting examples of AMR deployment in different industries:

Manufacturing and industry: SICK

The combination of 27 autonomous mobile robots, an automated small parts warehouse using a stacker crane and SAP® EWM create efficient and transparent production logistics for sensor manufacturer SICK at their location in Hungary. The new solution supports the company’s growth and reliably processes increasing order volumes. Find out more here >

Manufacturing and industry: FRONIUS

16 Open Shuttle Fork robots for pallet transport handle transport jobs of all kinds at Fronius. They form the link between goods-in, the production cells and goods-out. The new solution gives the company the necessary autonomy to flexibly make changes as needed and to manage both manual and automatic transport orders in the same system. Find out more here >

Polymer processing: DIGMESA

Swiss company Digmesa develops and distributes flow measurement devices. Taking only four months to implement, the solution initially included one Open Shuttle and was later expanded. The Open Shuttle supplies the injection molding machines with empty containers and transports the finished parts away. A flow rack serves as a buffer. Find out more here >

Would you like to learn more about the challenges in the plastics industry and which automation technologies help overcome them? Learn more in this blog post: Automation for the Plastics Industry >

Automotive: MAGNA

Magna, one of the world’s largest automotive suppliers, makes side mirrors at their Assamstadt, Germany, location. To evolve with the current shift in logistics and operate flexibly with a high level of value creation, the company opted for a combination between our automated storage and picking system Evo Shuttle and our Open Shuttle AMRs. The automation solution supplies production and assembly just in time and just in sequence. Find out more here >

Open Shuttles: AMRs by KNAPP

Our Open Shuttles are autonomous mobile robots that carry containers and pallets around warehouses and production facilities. They require no extra infrastructure, navigate freely and flexibly adapt to processes and the building layout. The different models – AMRs for containers or for pallets – ensure efficient supply of materials, increasing productivity and maximizing transparency of internal material flows.

Explore the diverse range of applications for automated container and pallet transport on our website Open Shuttles by KNAPP or in our blog post What Are Autonomous Mobile Robots? A Guide.

Interested in autonomous mobile robots?

We’re happy to tell you more!

Further reading recommendations

Additional Information

More information about the Open Shuttles from KNAPP: