Schukat electronic completely redesigns

their distribution processes with OSR Shuttle Evo

Solving the challenges of the time in innovative ways. This is one goal pursued by Schukat electronic. It’s also the reason the German specialist in electronic components decided to make the largest investment in company history and build a top-notch logistics centre with an OSR Shuttle Evo as its core element. In this way, Schukat electronic completely redesigned their distribution processes and created enough new performance capacity to last until 2030. Why did the company consciously choose automation and what advantages does the system offer for today as well as for the future? Find out more in this post.

in OSR Shuttle Evo

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationStrong growth needs innovative logistics

Monheim am Rhein, Germany: Schukat electronic supplies around 10,000 B2B customers in 50 countries worldwide from this location. For many years, the company has experienced considerable growth, recording gains of up to 10 percent. Georg Schukat, Managing Director and owner explains what matters as a specialist in the electronics business.

In our business, speed and precision are of utmost importance. We have both the low-volume daily business, which is all about delivering from stock as fast as possible, and large-volume forward transactions. Here, it’s all about delivering individual customer orders on a fixed date. In both areas of business, we aim to offer our customers the best possible service for the best price. This also includes regularly offering new, innovative services and expanding our product portfolio.

New demands require new solutions

The passion to innovate is one of the company values and is foundational to the Schukat electronic success story. It was this passion for innovation that led to the decision to build a sophisticated logistics centre. Initially, it was not clear whether the company really wanted to invest in automation technology, explains Thomas Reichmann, aide to the Managing Directors, “This desire for automation actually arose from the project and from other issues related to it. There were also economic concerns, such as, ‘Will this solution be profitable by 2030?’ We wanted a solution that offered us the flexibility we needed to expand. When we decided to automate, the question was, ‘Stacker crane or shuttle?’”

At first, we thought the shuttle system would be too expensive, but during discussions, we figured out how to evaluate the economic end of things. Performance was also considered in the decision. The OSR Shuttle Evo offers us the ability to scale up when we need the performance.

OSR Shuttle Evo brings highest efficiency for today, maximum flexibility for tomorrow

This is what the OSR Shuttle Evo stands for because this new generation of automated storage systems was developed for current challenges in logistics such as:

The flexibility of the OSR Shuttle Evo was the decisive factor that convinced Schukat electronic.

To be able to respond adequately to tomorrow’s business, we were looking for a highly-flexible overall solution. The flexibility that KNAPP’s new system approach offers with the OSR Shuttle Evo was exactly what we were looking for. We now have a unique opportunity to separate performance from storage capacity, where each can be separately increased as needed. The high system stability and the commercial aspects of the system also spoke in favour of the OSR Shuttle Evo.

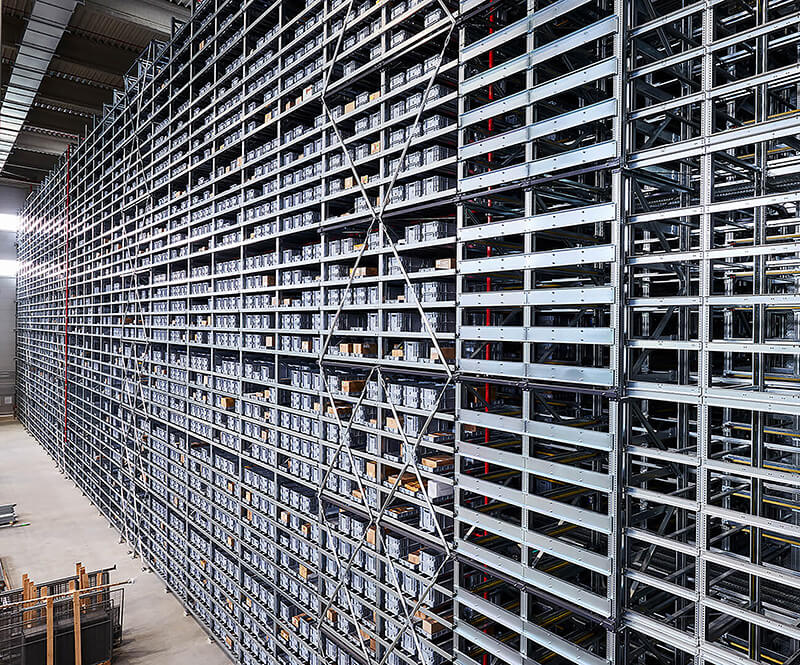

OSR Shuttle Evo: The expandable shuttle system

Flexibility plays a very special part in the OSR Shuttle Evo because performance and storage capacity function independently of each other. The shuttle system at Schukat electronic is designed to grow. The system currently comprises 4 rack line systems with 34 levels and 64,000 storage locations, with 68 shuttles and 2 lifts automating the racks. The flexible system structure offers the company capacity for future growth. The completed project will include 10 rack line systems with 140,000 storage locations, 140 shuttles, 4 lifts as well as 12 goods-to-person work stations for efficient order processing. “In my view, the special charm of the solution lies in the asymmetrical scalability, which we could only achieve with the OSR Shuttle Evo. We call this approach ‘design on point’. This means that Schukat electronic can adapt the system as needed and can get the most out of the system in terms of profitability and performance in every stage of the expansion. The number of storage locations can be increased by 150 % over the coming years, with the shuttle performance and the number of work stations doubled. This is ideal, especially for the extensive and continuously growing range of electronic articles”, says KNAPP`s Wolfgang Ferk.

Maximum storage density and use of space for a broad range of goods

Schukat electronic uses the OSR Shuttle Evo as a central storage system for about 35,000 articles. The broad range of small parts such as power suppliers, semi-conductors or ventilators are efficiently stored and picked. Schukat electronic also provides special services for their customers. Because of the tremendous range of articles, optimal storage density and space efficiency were particularly important ideas factored into the design of the new shuttle system. The system offers 64,000 storage locations for various containers and trays.

All articles available at all times

Another special feature of the OSR Shuttle Evo is that every article in the system can be accessed from every goods-to-person work station. This means that the workload can be evenly distributed among all the work stations and the availability of the articles in shuttle system is also increased. Schukat electronic currently has 6 goods-to-person work stations, where 1,200 order lines per hour can be processed. The number of work stations can be doubled.

Our statistics have shown that without automation technology and goods-to-person picking, our employees would have to walk up to 10 kilometres per shift in order to fulfil our performance goals. Naturally, this is unacceptable, which is why we are now using the goods-to-person principle for order processing. This type of working is less physically strenuous for our employees and they can also process orders faster, which increases throughput.

Efficient logistics processes for individual customer orders with OSR Shuttle Evo

The special strength of Schukat electronic is supplying customer-specific orders, no matter how great or small. The OSR Shuttle Evo enables Schukat electronic to offer their customers customized service. Therefore, the flexibility of the OSR Shuttle Evo has an immediate and positive effect on the customers.

Partnership is the key to succes

Passion for innovation, experience and a healthy portion of courage paired with a balanced partnership – this is the best approach to overcome new challenges. These values unite Schukat electronic and KNAPP, as Georg Schukat agrees, “I’m proud that I still enjoy striking out in new directions. This is why working with KNAPP was so interesting for us. KNAPP recognized that their customers have ideas and needs, and they are willing to actively work on these tasks and to forge new paths. We also value sustainable, long-term collaboration with customers and suppliers – another value we share with KNAPP.” Wolfgang Ferk works in Sales at KNAPP and worked with Schukat electronic in the sales phase and confirms the outstanding collaboration and partnership, “Open communication and a hands-on mentality are important to us, especially for a project like this where we integrated a new technology. Schukat electronic placed their bets on our new OSR Shuttle Evo with the knowledge that an innovation always comes with a certain amount of risk. We are truly thankful for their trust and are delighted that we could successfully realize the project together.”

I’m proud that I still enjoy striking out in new directions. This is why working with KNAPP was so interesting for us. KNAPP recognized that their customers have ideas and needs, and they are willing to actively work on these tasks and to forge new paths.