Robotics in logistics

Confucius said: “A man who lacks reliability is utterly useless.” We completely agree with the Chinese master. However, it’s not just unreliable people who make us lose our patience. In the age of automation, we expect machines to provide us with reliable support and to operate without any problems, particularly when it comes to working with staff. It’s crucial that workers can rely on machines to work properly at all times.

In logistics especially, the demands placed on robotics are incredibly high. Ultimately, the increasingly high demands for quality and performance have to be met in the face of diverse article ranges, cost pressure, lack of space and shortage of workers. Industrial robots must therefore be robust, handle errors automatically and deliver a consistently high performance.

Flexibility and consistently high performance

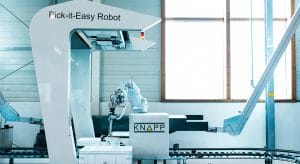

The Pick-it-Easy Robot embodies all of these features. Our highly dynamic robotic picking cell is already proving just this at numerous customers from the world of industry. The Pick-it-Easy Robot can be integrated into an existing master concept and can be used in combination with manual pick stations and shuttle systems. It is therefore part of a comprehensive, integrated picking system that is both reliable and flexible. Thanks to its sophisticated gripper technology, it decides automatically which gripper in its toolbox is most suited to handle the articles, taking their category, dimensions and weight into consideration. As a result, the robot can handle a wide article range with ultimate reliability and guarantees high availability around the clock.

Autonomous error handling

Should an error crop up nonetheless – should the most suitable grip point not be found for an article, for example – not to worry! The Pick-it-Easy Robot can detect and correct errors autonomously, all thanks to the interplay between cutting-edge image recognition and processing technology, software algorithms and peripheral sensor elements.

The zero-defect principle

Through its intelligent error handling and consistently high performance, the Pick-it-Easy Robot is the perfect embodiment of KNAPP’s zero defect principle. As part of this, KNAPP pursues the three crucial elements reliability, accuracy and traceability in order to guarantee customer satisfaction and success. With the zero-defect approach, intralogistics that is even more flexible, economical and particularly error-free, is now more than ever, the number one aim.

Thanks to its intelligent error handling and consistently high performance, the Pick-it-Easy Robot perfectly reflects KNAPP’s zero defect philosophy.

Interplay between man and machine

The constant enhancement of robotics and automation is also changing the working environment of employees in logistics; monotonous tasks are a thing of the past as workers are freed up to concentrate on value-adding and creative activities. Man and machine do not compete with each other – together they make a strong team.

Pick-it-Easy Robot

- Fully-automatic picking solution for logistics applications

- Can be used combined with automated storage systems and manual picking work stations. This results in an ideally coordinated picking system.

- Processes a wide article range thanks to different grippers and a fully-automatic gripper change

- Also suitable for delicate articles

- Functions: Dropping, careful organized placement, separating, merging

- Integrates into existing KNAPP systems

- Robust and low-maintenance

- Picking performance: Up to 1,200 items per hour

- Named as best product at the LogiMAT 2017

Further reading recommendations

Machine learning is everywhere. But what exactly lies behind this future technology? Is it really possible to teach machines to learn? What advantages does it offer– and where does KNAPP come into play? Let’s take a closer look.

Thanks to its intelligent error handling and consistently high performance, the Pick-it-Easy Robot perfectly reflects KNAPP’s zero defect philosophy.

Robots and artificial intelligence have long inspired people’s imagination. For logistics, robots offer countless possibilities.

Additional Information

More information: