New retail booming in China

E-commerce in China has developed rapidly in the past decades, with current over 25% of total retail sales generated online. Especially due to COVID-19 pandemic, consumers increasingly shift from offline to online shopping and e-commerce market is expected to grow from about $2.1 trillion in 2021 to $3.0 trillion in 2024.

As omnichannel provides the seamless and convenient shopping experience, by simply clicking consumers can place orders anytime, anywhere and get the products by the same day or next day. Meanwhile, livestreaming becomes the hottest trend to sell products online, which will grow by 95.5% this year. Digitalization and development of logistics technology are the driving force behind the scenes, which are even more obvious in the peak time.

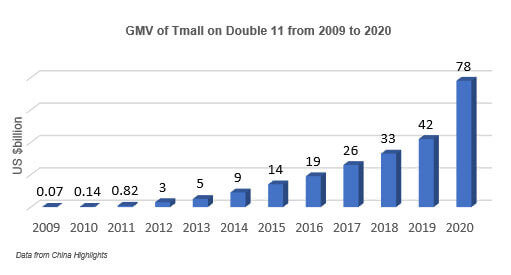

Double 11 witnesses record-breaking online sales

Double 11, known as the biggest online shopping festival in the world, was originally initiated by Alibaba on Nov.11th in 2009 and adopted by other e-commerce platforms and retailers. With the shopping fever generated by customers nationwide, double 11 witnesses breaking sales records each year. For example, the gross merchandise volume of Alibaba Tmall has increased from $5 billion in 2013 to $78 billion in 2020 as below chart. On the contrast, the total sales of Black Friday and Cyber Monday in US was around $19.8 billion in 2020. Though Tmall counts about 50% of the total Chinese B2C E-commerce market share, China’s large population and the growing middle class show big consumption potential.

Moreover, 2021 Double 11 Festival marks the largest to date, with over $139 billion of sales generated in major E-commerce platforms like Tmall and JD.com. Different from the past when event was only held on Nov.11th, this year’s event featured with two sales windows on Nov.1-3 and Nov.11, and the pre-sale for first sales window started from October 20th for allowing consumers to secure the orders by paying a deposit and the balance to be paid on the official sales. For example, JD’s Single Day Grand Promotion started at 8pm on Oct.31st, with 190 million products were sold within 4 hours.

In the meanwhile, the fragmented and complex orders bring big pressure for logistics to handle billions of parcels. Even under COVID 19 situation, totally around 675 million parcels for orders from all online platforms were delivered during double 11 in 2020, and the volume is estimated to increase yearly by 26%.

Intelligent intra-logistics solution paves the way

Regarding the tremendous number of parcels, it’s crucial to apply parcel prediction technology and modify the logistics plan without overwhelming the warehouse capacity or keeping customers waiting too long. Since recent years, the double 11 started pre-sale early from end of October, so that the products can be brought to front-end warehouse or stores which are close to the end customers, afterwards the delivery can be done efficiently.

For the status quo, the amount of central distribution center and regional distribution center is not enough, and the automation rate is relatively low. Most warehouses rely on humans to manually proceed the warehouse processes, despite of several shifts, the efficiency is still low and error rate is high. Nevertheless, online purchase has high return rate which brings more complexity for the reverse logistics. Thus, an intelligent warehouse solution is highly essential to empower the efficiency of order fulfillment for a modern distribution center.

Proven solution empowers the E-commerce giant

The E-commerce giant, providing over 500 million active customers with direct access to an unrivalled range of products, runs its own vast logistics network nationwide. Thanks to the sophisticated logistics technologies, most of orders can be delivered to customers within the same day. Among its national logistics parks, Beijing project is one of the biggest and the most advanced distribution center in North China area, which has been designed especially for consumer electronics. The project has equipped with the most advanced logistics technology, including OSR Shuttle™ system in collaboration with the global leading logistics solution provider KNAPP.

The OSR Shuttle™ system is 19-levels high, which greatly improves the efficiency of storage and picking performance. Compared to traditional warehouse, the capacity of shuttle system storage increased 10 times, and the automated goods-to-person picking is 8 times more efficient than manual picking. In the past, an operator can pick 1,000 orders per day by searching products all around the warehouse, picking, and putting into trolley, with walking around 40,000 steps. But now, an operator can easily pick about 8,000 orders per day by standing in the ergonomically designed Pick-it-Easy station, and simply picking products guided by user-friendly (easyUse) picking screen (GUI) and picking lights. The picking efficiency has increased 8 times, but the walking distance has decreased 10 times.

OSR Shuttle™ is the all-in-one solution, including processes from inbound, picking, inventory and outbound. Thanks to the precise sequencing by the automated intelligent shuttle solution, products will be automatically transported in the required sequence to the picking station, the workload of warehouse operators has been greatly decreased and the efficiency of order fulfillment has been enhanced vastly. Especially in the peak season, the promised high-efficiency and quality of delivery is essential for satisfying end customers and increasing the repurchase rate and customer retention rate.

All-round customer service keeps performance up to par

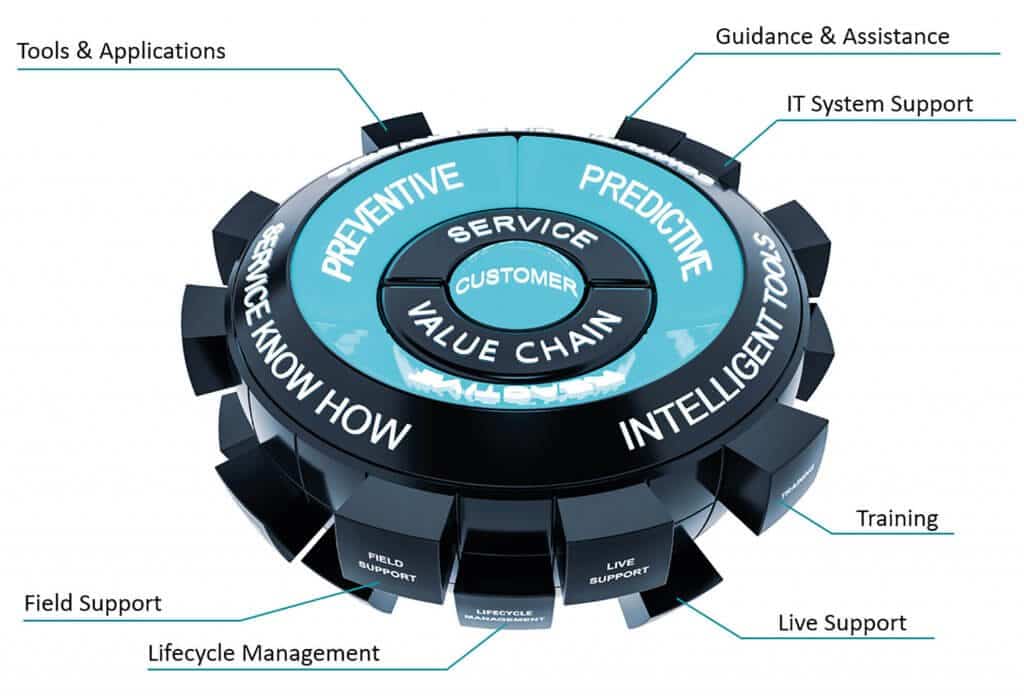

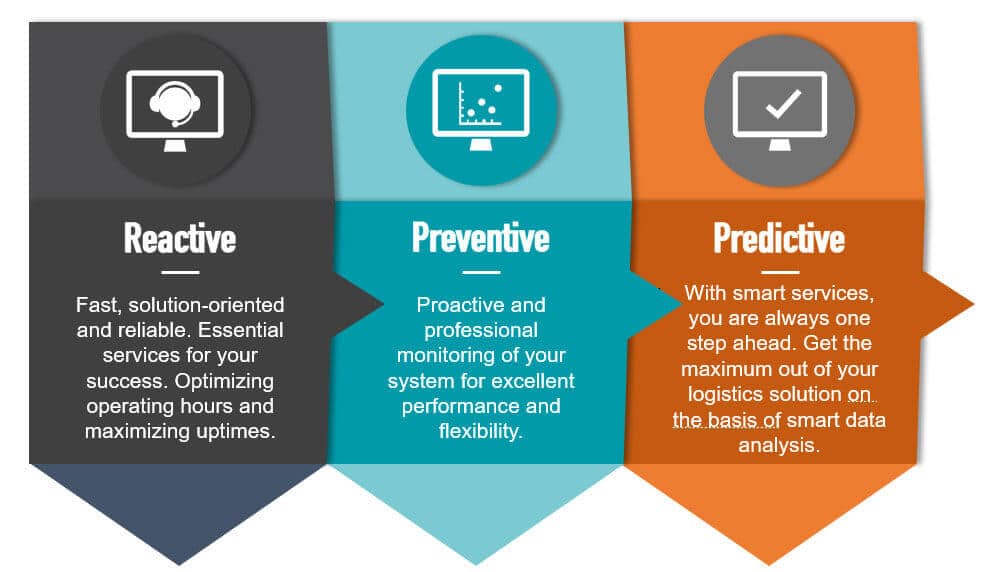

KNAPP also provides service for its systems which ranges from all-round care, lifecycle management, regular guidance and training for customers, to intelligent IT systems and tools, and features both live support as well as local support on site.

For the online giant, Resident Engineers and Service Desk support are provided 365 days a year to ensure smooth operation. The KNAPP Resident Engineers and Service Desk provide top-quality reliable service, especially during peak periods. Our well-trained and experienced onsite technicians can help the customer’s team solve mechanical and electronic issues promptly. Furthermore, preventive inspection and routine maintenance tasks are carried out to make sure the equipment remains in a good operational condition, maximizing the uptime. The whole warehouse workflow is also well-monitored through the visualization tool SCADA and KiSoft Navigator.

Additionally, the KNAPP Service Desk is available any time within the contracted hours. Our professional technicians can detect and solve issues remotely within a very short response time, eliminating or limiting effects on operations. The system’s robust features in combination with the rapid response of the service team are key advantages that help to ensure continuous peak operation.

KNAPP is the world’s leading logistics solution provider, with many successful projects and customers in various sectors including retail. KNAPP was the first to launch a shuttle system and now has more than 40,000 shuttles in operation worldwide. Proven intelligence, robust features and unbeatable service are why this online giant selected KNAPP. This partnership will continue for the long term, both locally and globally.

Further reading recommendations

The storage system solution at Amorepacific is the largest project KNAPP has ever implemented in South Korea.

Just a click or two puts clothes, fresh produce, electronic items and much more in your online shopping cart. The effects of the COVID-19 pandemic just made the boom in online shopping even greater. That’s why it makes sense to understand the advantages of efficient e-commerce fulfilment and how a tailor-made logistics solution is created.

The holiday season is at hand. Are your fulfillment centers adequately staffed, stocked and equipped? Use this handy checklist to assess your retail logistics readiness.