Retail Logistics for E-commerce,

Omnichannel and Brick and Mortar Retail

Whether cosmetics, electronics or lifestyle products, retail today is super-dynamic and diverse. By rethinking your retail logistics today, you can achieve efficiency and genuine customer experience across all your channels. Intelligent logistics solutions convert complexity into real advantage.

Retail logistics that master the diversity

In today’s modern retail, every second counts: Customers expect same-day or next-day delivery, simplified handling of returns and a consistent shopping experience whether they are online, at the store or on their phones. In parallel, demands for transparency and efficiency are on the rise.

We are meeting the challenges with sophisticated solutions for retail logistics. Our systems for omnichannel fulfillment and e-commerce logistics ensure smooth processes from incoming goods to the last mile. Returns are processed intelligently, orders picked precisely, and processes adapted flexibly to peaks in demand.

We combine our many years of experience in the retail sector with scalable logistics solutions – for companies who are thinking about tomorrow today.

Anton Tschurwald, Christoph Lafer

Vice Presidents Retail and Lifestyle Solutions, KNAPP

Do you have any questions?

We are always glad to help you!

Email: sales@knapp.com

#passion4retail

Would you like to know more about our efficient logistics solutions for retail?

Boosting retail brands to new heights

Our solutions for retail logistics

Automated storage systems for retailers

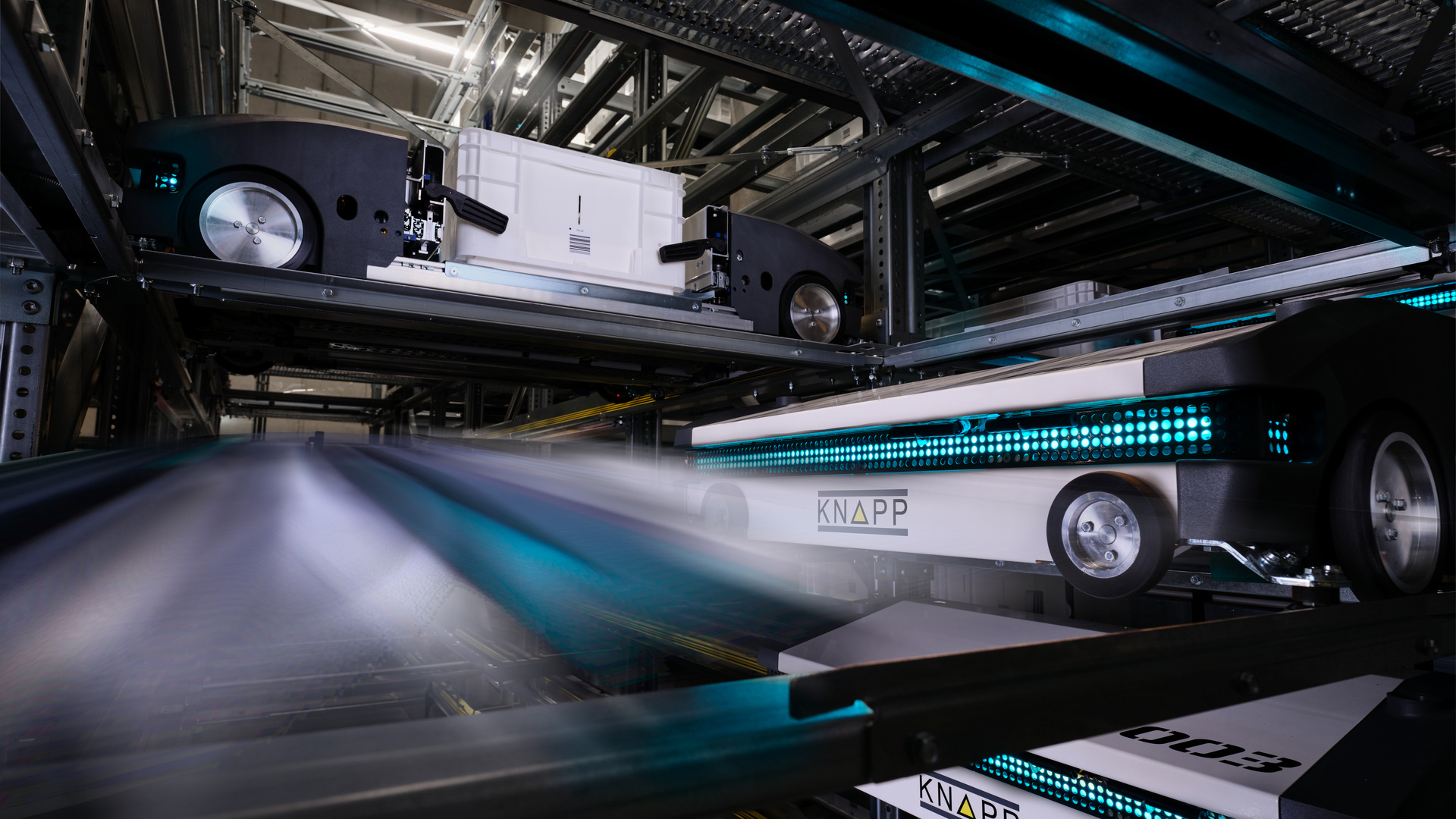

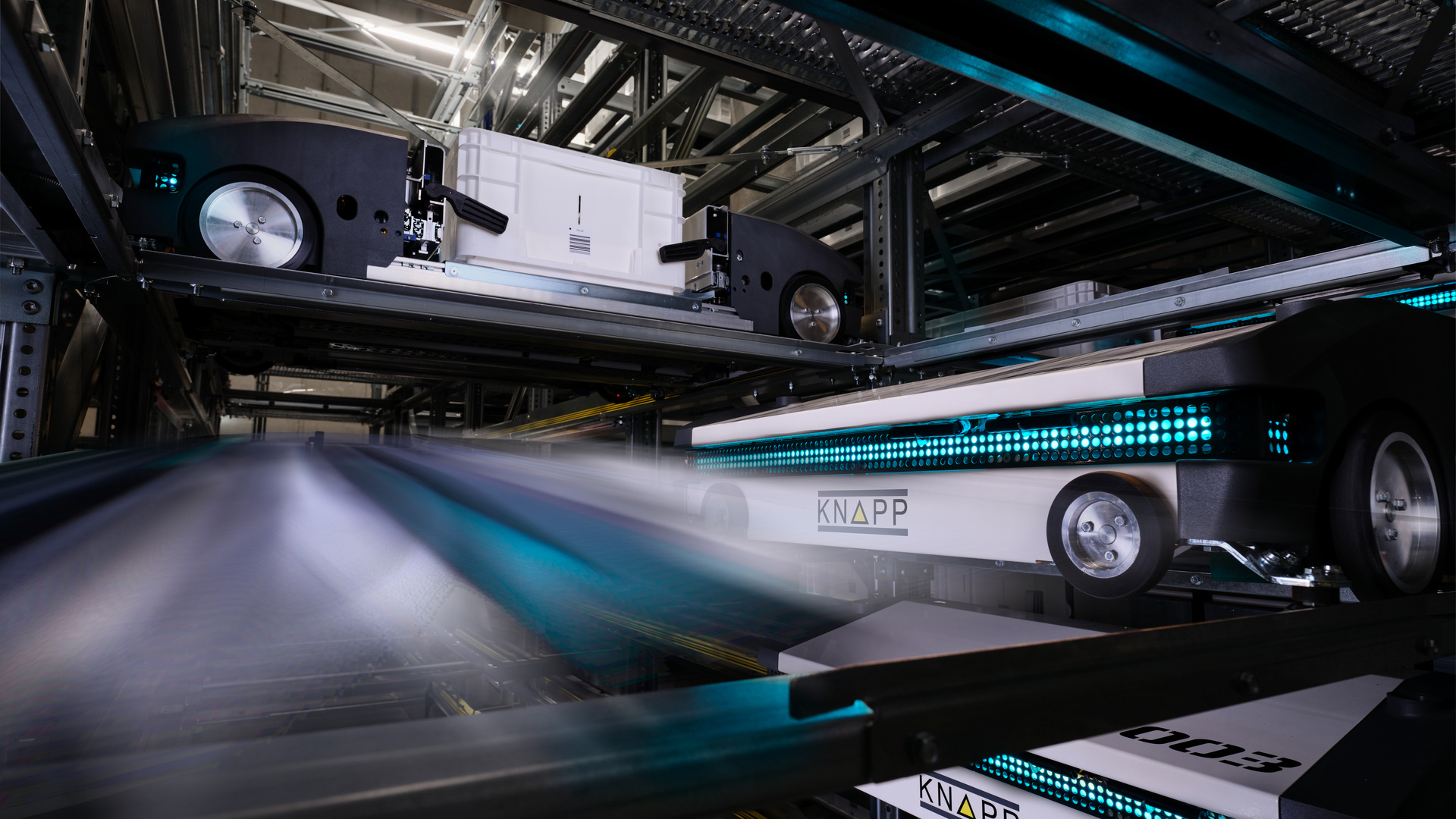

For our retail customers, we focus on automated storage and retrieval systems using shuttles, bots and stacker cranes. They provide space-effective storage as well as efficient picking, buffering and sequencing of various types of products.

Discover our portfolio of high-performance solutions:

Convey, sort and handle everything from cosmetics to electronics

Whether carton, tray or single item – our conveyor and sorting solutions get your retail logistics moving. Using solutions like pocket sorters and modular conveyor systems, efficient returns processing, sorting to target chutes and flexible item handling all become possible.

Discover more about our systems:

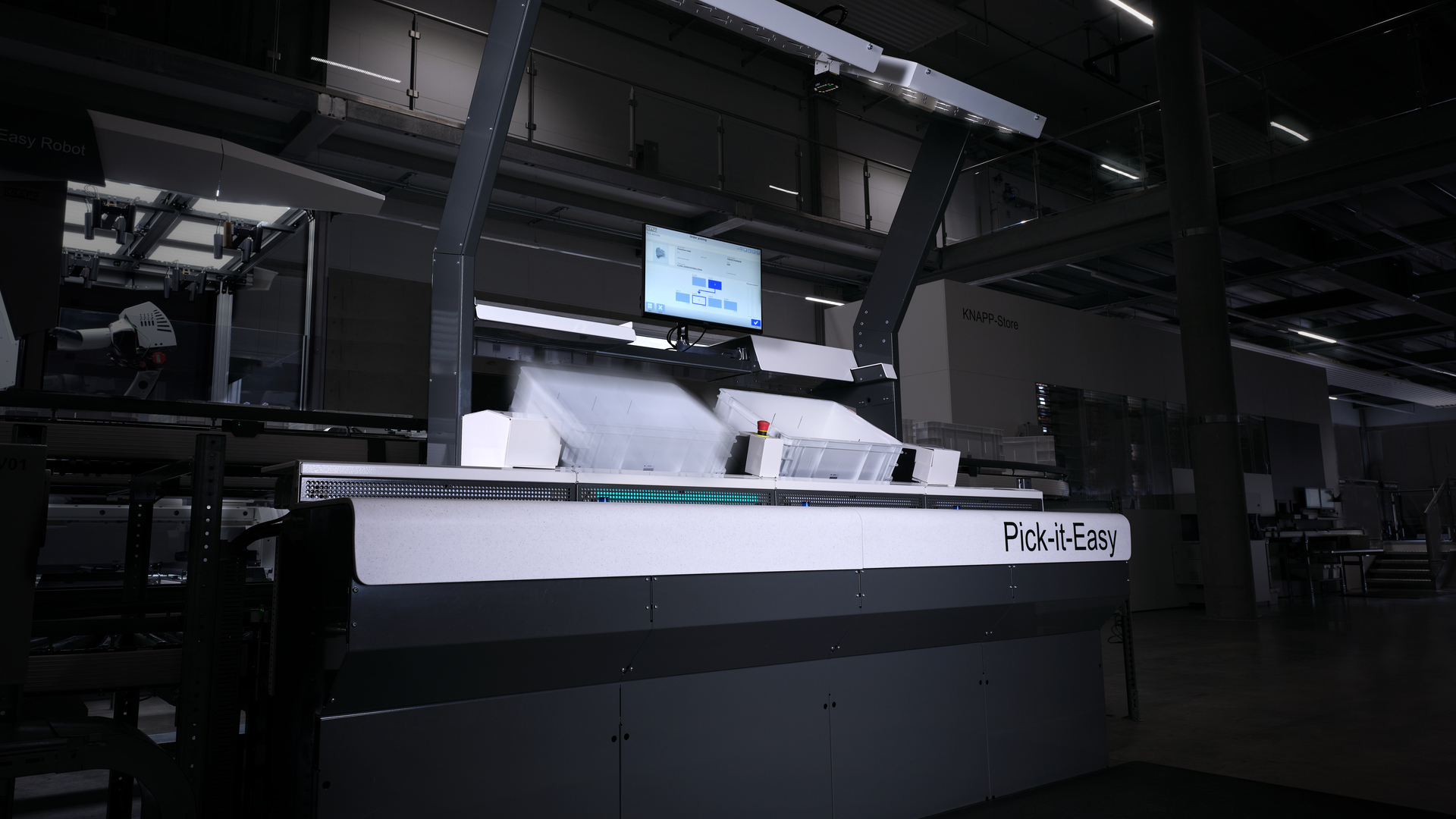

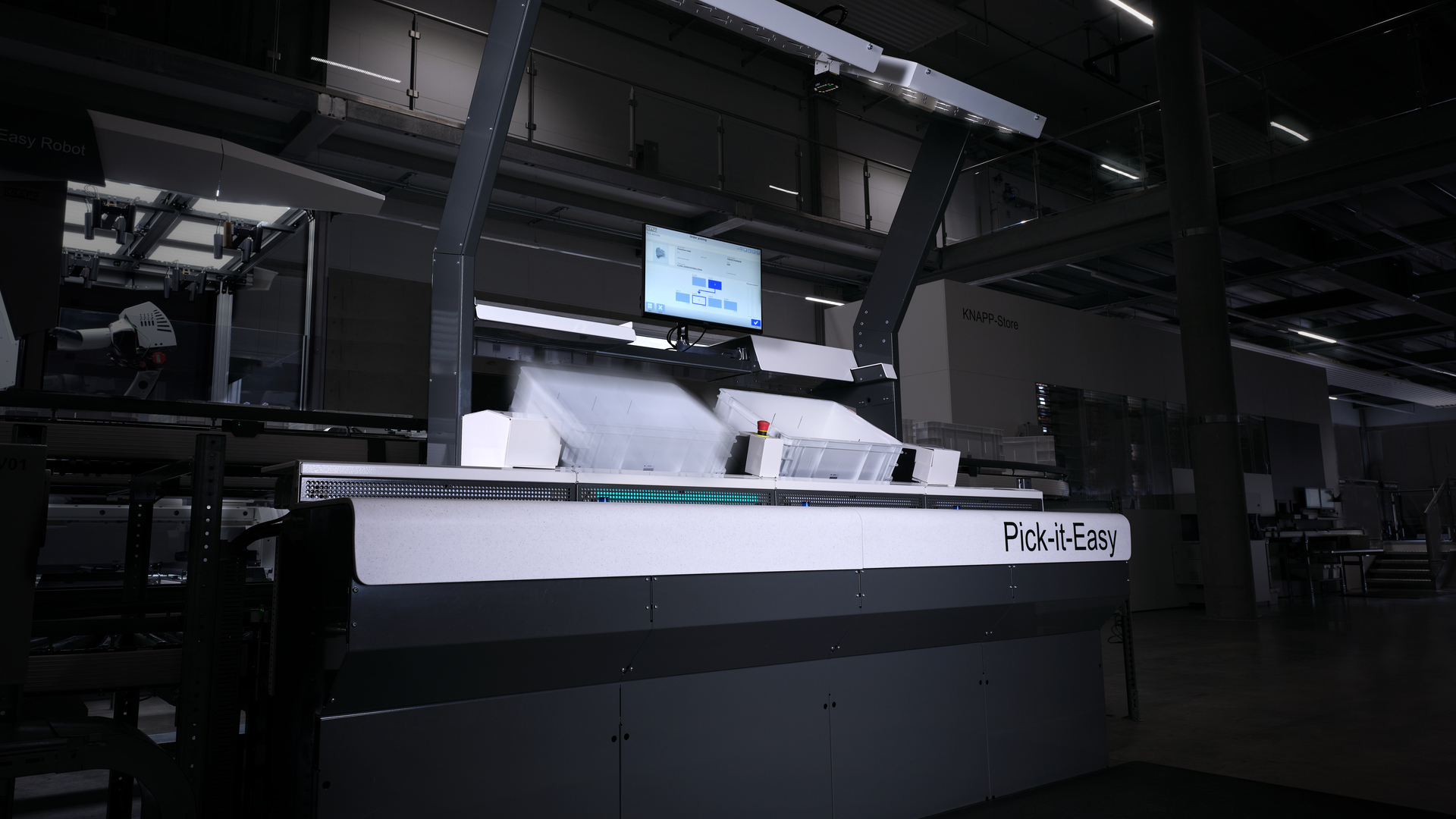

High-tech work stations for retailers

Our ergonomic work stations use technology to guide the user and are ideal for processes such as picking, inventory and processing returns. Since the work stations are directly integrated into the system, they are supplied with items precisely when and where needed. This reduces errors while increasing productivity.

Find out more about goods-to-person picking:

Efficient pallet handling

For goods on pallets, we offer automated solutions including stacker cranes and palletizing robots. These can be seamlessly integrated and are ideal for high stock turnover rates, a variety of item sizes and store-friendly deliveries.

Find out more about our solutions for automated pallet handling:

Intelligent software for connected retail logistics

With our all-in-one software solution, you can control, monitor and optimize all the logistics processes along the retail supply chain – from stock management to analysis. The result: maximum transparency, efficiency and the ability to respond, all from a single source.

Find out more about our software portfolio:

Our solutions for retail logistics

Automated storage systems for retailers

For our retail customers, we focus on automated storage and retrieval systems using shuttles, bots and stacker cranes. They provide space-effective storage as well as efficient picking, buffering and sequencing of various types of product. Discover our portfolio of high-performance solutions:

Convey, sort and handle everything from cosmetics to electronics

Whether carton, tray or single item – our conveyor and sorting solutions get your retail logistics moving. Using solutions like pocket sorters and modular conveyor systems, efficient returns processing, sorting to target chutes and flexible item handling all become possible.

Discover more about our systems:

High-tech work stations for retailers

Our ergonomic work stations use technology to guide the user and are ideal for processes such as picking, inventory and processing returns. Since the work stations are directly integrated into the system, they are supplied with items precisely when and where needed. This reduces errors while increasing productivity.

Find out more about goods-to-person picking:

Efficient pallet handling

For goods on pallets, we offer automated solutions including stacker cranes and palletizing robots. These can be seamlessly integrated and are ideal for high stock turnover rates, a variety of item sizes and store-friendly deliveries.

Find out more about our solutions for automated pallet handling:

Intelligent software for connected retail logistics

With our all-in-one software solution, you can control, monitor and optimize all the logistics processes along the retail supply chain – from stock management to analysis. The result: maximum transparency, efficiency and the ability to respond, all from a single source.

Find out more about our software portfolio:

Are you interested in other solutions for retail logistics?

Advantages for retail logistics

No matter the logistical challenge, our logistics solutions for retail are tailored to suit your particular requirements:

Efficient returns management

Respond flexibly to peaks in demand

Shop-friendly delivery

Same-day or next-day delivery

Omnichannel fulfillment in a single system

Precision in every step of the way

References:

Successful customer projects in retail logistics

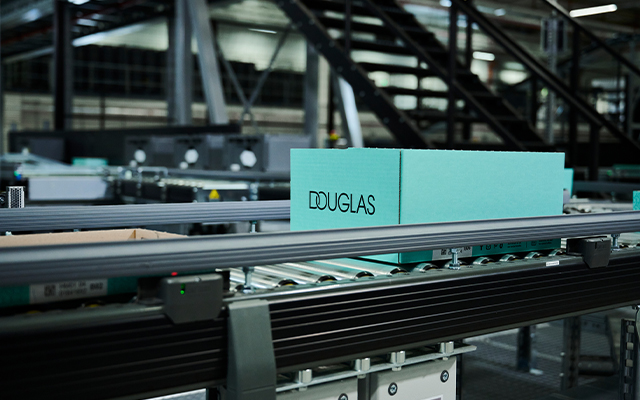

Arvato and DOUGLAS Group: Omnichannel logistics

In Germany, Austria and Switzerland, 3PL provider Arvato uses a comprehensive KNAPP solution – the largest 2D shuttle solution for cosmetics in the world – to provide optimized omnichannel fulfillment for their customer, the DOUGLAS Group.

Victorinox: Worldwide distribution from a central location

Victorinox, a Swiss company of long-standing tradition, built their first automated warehouse with KNAPP, which features smart software and modern technology for central control and transparency for their worldwide deliveries.

The Very Group: Intelligent software for peak performance

Using KiSoft Analytics, The Very Group can master sales peaks such as Black Friday. The software provides the data for predictive planning and optimizes logistics processes.

Radial and doTERRA: Compact automation solution for e-commerce

To provide efficient e-commerce fulfillment for doTERRA, 3PL provider Radial depends on our compact automation solution. A scalable A-frame automated picking system provides efficient picking.

Walmart: Next Generation Fulfillment Center

Leading retailer Walmart relies on our customized logistics to optimize the processes in 5 distribution centers. Automating processes reduced the manual process steps from 12 to 5.

ASICS: Efficient sporting goods logistics for B2B customers

ASICS relies on our automated logistics process to supply B2B customers efficiently. The system provides rapid lead times and high delivery quality even during peak periods.

References:

Successful customer projects in retail logistics

Arvato and DOUGLAS Group Omnichannel logistics

In Germany, Austria and Switzerland, 3PL provider Arvato uses a comprehensive KNAPP solution – the largest 2D shuttle solution for cosmetics in the world – to provide optimized omnichannel fulfillment for their customer, the DOUGLAS Group.

Victorinox: Worldwide distribution from a central location

Victorinox, a Swiss company of long-standing tradition, built their first automated warehouse with KNAPP, which features smart software and modern technology for central control and transparency for their worldwide deliveries.

The Very Group: Intelligent software for peak performance

Using KiSoft Analytics, The Very Group can master sales peaks such as Black Friday. The software provides the data for predictive planning and optimizes logistics processes.

Radial and doTERRA Compact automation solution for e-commerce

To provide efficient e-commerce fulfillment for doTERRA, 3PL provider Radial depends on our compact automation solution. A scalable A-frame automated picking system provides efficient picking.

Walmart: Next Generation Fulfillment Center

Leading retailer Walmart relies on our customized logistics to optimize the processes in 5 distribution centers. Automating processes reduced the manual process steps from 12 to 5.

ASICS: Efficient sporting goods logistics for B2B customers

ASICS relies on our automated logistics process to supply B2B customers efficiently. The system provides rapid lead times and high delivery quality even during peak periods.

Frequently asked questions (FAQs) about retail logistics

Sustainability plays a central role in today’s logistics strategies. The best way to make logistics sustainable is by combining resource-saving technologies with intelligent design:

- Eco-friendly packaging: Using sustainable materials reduces the product’s ecological footprint.

- Custom-sized packaging solutions: Right-size packaging minimizes the amount of packaging waste and optimizes the use of space in transports.

- Efficient use of space: Intelligent planning and compact system designs reduce the amount of space required.

- Life cycle management: Existing systems are modernized, saving resources and extending their service life.

- Optimized delivery routes: Smart route planning and decentralized warehouse structures shorten transport distances and lower emissions.

All these measures help combine ecological responsibility with economic efficiency – an important step toward more sustainable retail logistics.

Efficient returns processes are key for success in retail. Maximizing efficiency means focusing on intelligent automation and data-based control systems:

- Digital recording and inspection: Software provides vital assistance in receiving, checking and, if needed, processing returns quickly and transparently.

- Automated refunds and re-integration into the warehouse: Refunds are issued automatically while returns are stored back into the system.

- Flexible warehouse zones: Fast movers are placed in dynamic buffer areas to ensure that they’ll be available again quickly.

- Efficient storage of slow movers: Items in lower demand are systematically stored to save space.

- Partially or fully automated processes: Processes can be designed as needed to either receive manual support or to function fully automatically.

- Data-based analysis and prognosis: Intelligent software can create return prognoses and provide support for strategic decision-making.

These solutions do more than just make your reverse logistics processes faster and more cost-efficient – they also make them more customer-friendly and sustainable.

Peak periods such as Black Friday, Valentine’s Day, Christmas or Singles’ Day demand especially flexible and high-performing logistics processes. The following measures will help you manage them effectively:

- Prognosis-based planning: Demand is analyzed based on data, providing an early estimate of volume and allowing you to adapt personnel and resources accordingly ahead of time.

- Optimized storage strategies: Targeted placement and picking of items keeps processes speedy and ensures high availability during peaks.

- Data-driven decisions: Real-time data allows for ongoing analysis and adaptation of processes, including route optimization that takes current bottlenecks into account.

- Flexible use of the system: Storage and retrieval systems can be adapted dynamically to provide efficient fulfillment for both stores and e-commerce.

- Efficient returns management: After peak periods, return volumes soar. Automated processes speed up return storage and re-availability.

- Simulation and Health Checks: Simulations help you identify potential errors early and prevent them from occurring. Performing a Health Check on the installation lets you know whether all systems are functioning properly and are ready for peaks.

These measures make your logistics processes stable, scalable and customer-oriented – even when demand peaks.

When it comes to e-commerce, the last mile – that is, the journey from the warehouse to the customer’s doorstep – is decisive for customer satisfaction. Intelligent technologies and sophisticated logistics solutions greatly simplify the last mile process:

- Smart delivery routes: Our KiSoft software plans routes based on data, taking current traffic into account to reduce both delivery times and CO2 emissions.

- Mobile navigation and proof of delivery: An app guides drivers along their route and the handover process is documented digitally.

- Data-based optimization: Long-term evaluations provide valuable key figures for continuously improving the delivery process.

- Automated storage solutions: Systems such as the Evo Shuttle pick quickly and precisely, making them an ideal fit for the requirements posed by the last mile.

- Micro fulfillment centers: Small, automated warehouses near cities shorten delivery routes, save resources and improve customer satisfaction.

With these solutions, we make the last mile high-performance, flexible and sustainable – a major plus for retailers and consumers alike.

Whether you choose a central or decentral network depends on your own requirements and your company’s logistics strategy.

- Central warehouse: A large warehouse lets you enjoy economies of scale, lower operating expenses per unit and central control over your stock. It’s ideal for stable demand structures and for supplying multiple regions.

- Micro fulfillment centers: Small warehouses closer to consumers shorten delivery times, lower transport costs and improve flexibility – especially in urban areas or during major fluctuations in demand.

- Urban logistics: In urban areas, local warehouse solutions improve last mile delivery and help increase customer satisfaction.

The most efficient solution is often a combination of these two approaches, accounting for factors such as product range, delivery speed, infrastructure and cost structure.

Omnichannel fulfillment combines warehouse processes for both brick and mortar retail and e-commerce into one system. It allows for combined stockkeeping, picking for all sales channels and more flexibility for order fulfillment during peak periods – along with more efficient use of warehousing space and faster responses to changes in demand, allowing you to capitalize on synergies between the channels.

Single channel fulfillment, on the other hand, separates processes by sales channel. It’s advantageous when demand varies a lot because it allows you to focus on different packaging types, delivery times or service levels.

Global service network and a reliable partner

Our International Customer Service looks after your logistics system – around the globe, around the clock, 365 days a year. Discover more about our services, from seamless support to optimizing your system!

Are you interested in our logistics solutions for the retail sector?

What’s spurring logistics: Trends and developments

How can you turn your reverse logistics into a competitive advantage? Boost the efficiency of your returns processing with the right technologies and strategy to master returns handling and drive success.

and How Modern Logistics Provides Solutions

In logistics, the last mile frequently includes many hurdles to jump that require significant resources. Perfect planning and flexible processes are key to turning these challenges into advantages, such as positive customer experience and reduced costs.