Combination of AMR and automatic storage system

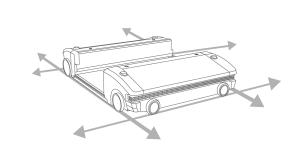

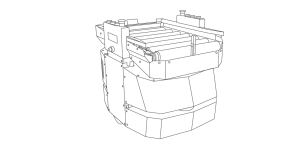

When combined with the autonomous vehicles, the Open Shuttles, the OSR Shuttle™ Evo becomes the intelligent and flexible system solution, the OSR Shuttle™ Evo+. The solution brings together the advantages of a high-performance shuttle system and the agility of an autonomous mobile robots (AMR). Goods, raw materials, overstock and buffered orders – everything is stored centrally in the OSR Shuttle™ Evo. The Open Shuttles supply different work stations in diverse warehouse areas directly from the OSR Shuttle™ Evo just-in-time.

In addition to the traditional supply of work stations, other work stations can also be integrated and automated, such as those for quality assurance, value-added services or other special processes. As a result, the system approach of the OSR Shuttle™ Evo+ allows systems and processes to be interconnected like never before and frees up new ways to organize transport routes.

With the OSR Shuttle™ Evo+, we are forging new paths for your success.

Your advantages with the OSR Shuttle™ Evo+

- Stock and overstock are stored centrally in the OSR Shuttle™ Evo

- OSR Shuttle™ Evo buffers and sequences goods and orders

- Structure and position work stations flexibly

- Integrate temporary work stations

- Interconnect all work stations and the shuttle system flexibly

- Height-adjustable Open Shuttles ensure all work stations are connected in an ergonomic way

- Integration of value-added services, quality checks and other processes

- Independent and separate goods flows thanks to the flexible Open Shuttles

- Simple integration of special processes or goods that would otherwise be costly to automate

- Expensive or sensitive goods transported securely

- Streamlined system design: Free up space by using Open Shuttles instead of static conveyor technology

- Inexpensive and easy to scale compared to static conveyor technology

- Freely scalable performance: Use any number of Open Shuttles in line with the workload

Further reading recommendations

Optimize intralogistics processes and increase performance using automation. What is the right level of automation for your operation? In this post, we present various levels from innovative manual warehouses up to fully automatic systems.

Autonomous mobile robots (AMRs) facilitate flexible, efficient transport processes. Whether deployed in manufacturing, food retail or in distribution logistics – their range of use is wide. Discover more about this future-oriented technology.

Additional Information

More information about OSR Shuttle™ Evo

More information about the autonomous mobile robots Open Shuttles