Warehouse Automation for Manufacturing

Warehouse automation is the key to more competitiveness in manufacturing because the production of the future is intelligent, flexible and interconnected. Our efficient solutions optimize your production supply and internal transport processes.

Intelligent production logistics for increased performance

An intelligent production logistics system, finely tuned, plays a central role in keeping manufacturers competitive when contending with the sector’s typical challenges. New approaches are required to succeed in the face of changing environmental and market conditions, skilled labor shortages, a lack of space and ever-increasing complexity. Here, warehouse automation is the key to increasing your company’s performance.

Looking for dynamic, highly interconnected systems with security of investment and maximum flexibility as requirements change? Our warehouse automation solutions are ready to boost quality, profitability, efficiency and ergonomics in your company’s operations. With new approaches and a mix of innovative and proven technologies, we are opening up new opportunities for the manufacturing sector. Our mission:

Understanding your business so our solutions provide the added plus in flexibility to your processes.

Do you have any questions? We are always glad to help you!

Stefan Lechner & Christian Brauneis-Lieb

Managing Directors KNAPP Industry Solutions

Email: kin.sales@knapp.com

"Process reliability is crucial for production, which is at the heart of every company, so we see it as our mission to develop the best possible solutions using our expertise. By using innovative technologies and intelligent software, processes are interconnected, optimally meshing and designed for high adaptability. With our all-in-one solutions, we make smart production a reality."

Christian Brauneis-Lieb

Managing Director KNAPP Industry Solutions

Are you interested in automating your company’s warehouse?

Find out more about our solutions and customer references!

Solutions for warehouse automation in manufacturing

Automated storage systems for efficient production processes

Whether automated small parts warehouses, storage robot systems, stacker cranes or buffer towers, we have the optimal logistics solution for every requirement. Our storage systems support processes such as picking, buffering, sequencing of both goods and orders as well as supplying work stations. Find out more about our smart solutions:

Automated storage and picking system for higher performance

The automated storage and picking system InduStore is an ideal solution for industrial applications, especially for stockpiling individual items, supplying production or storing spare parts. Discover more about the system:

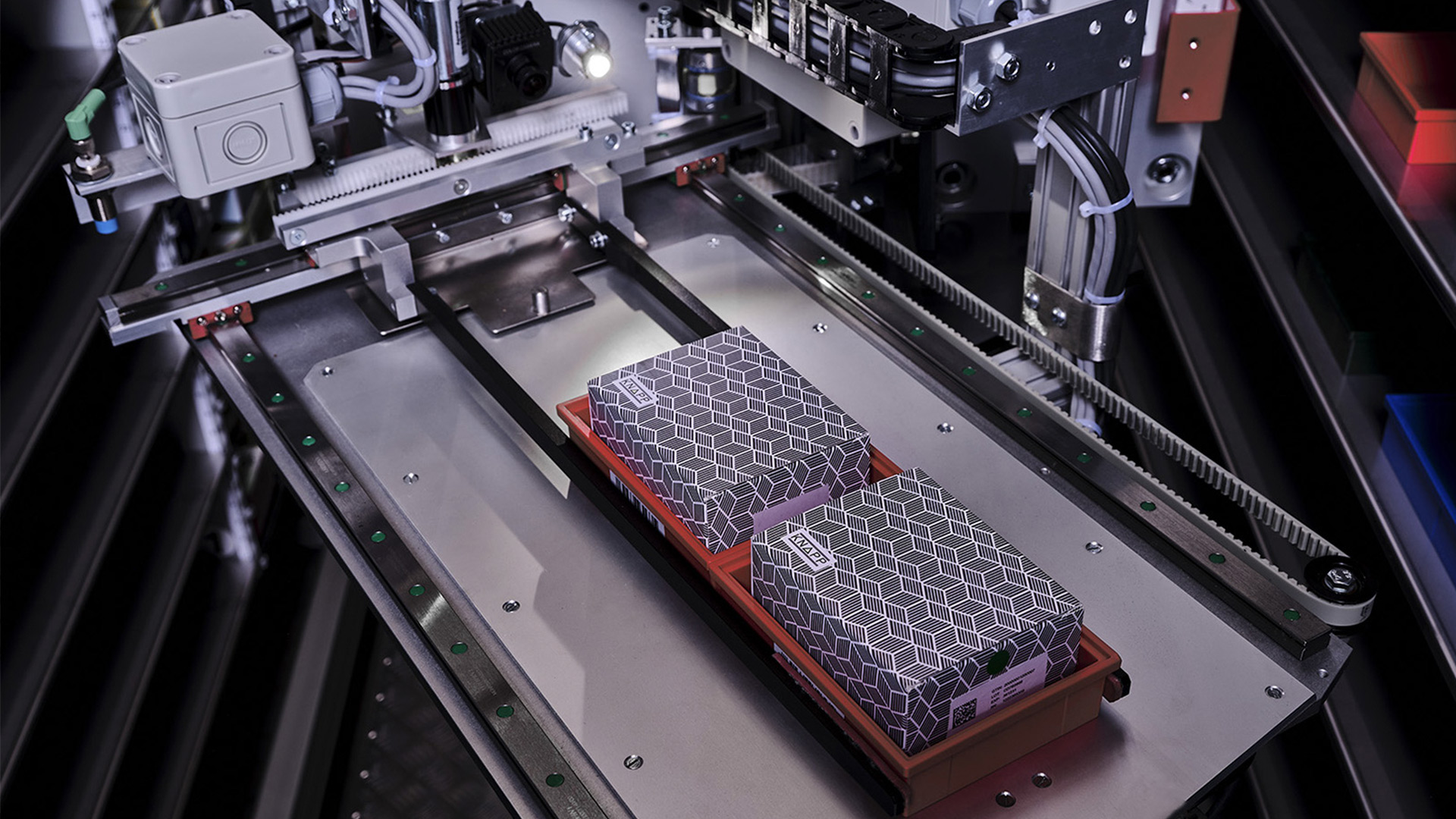

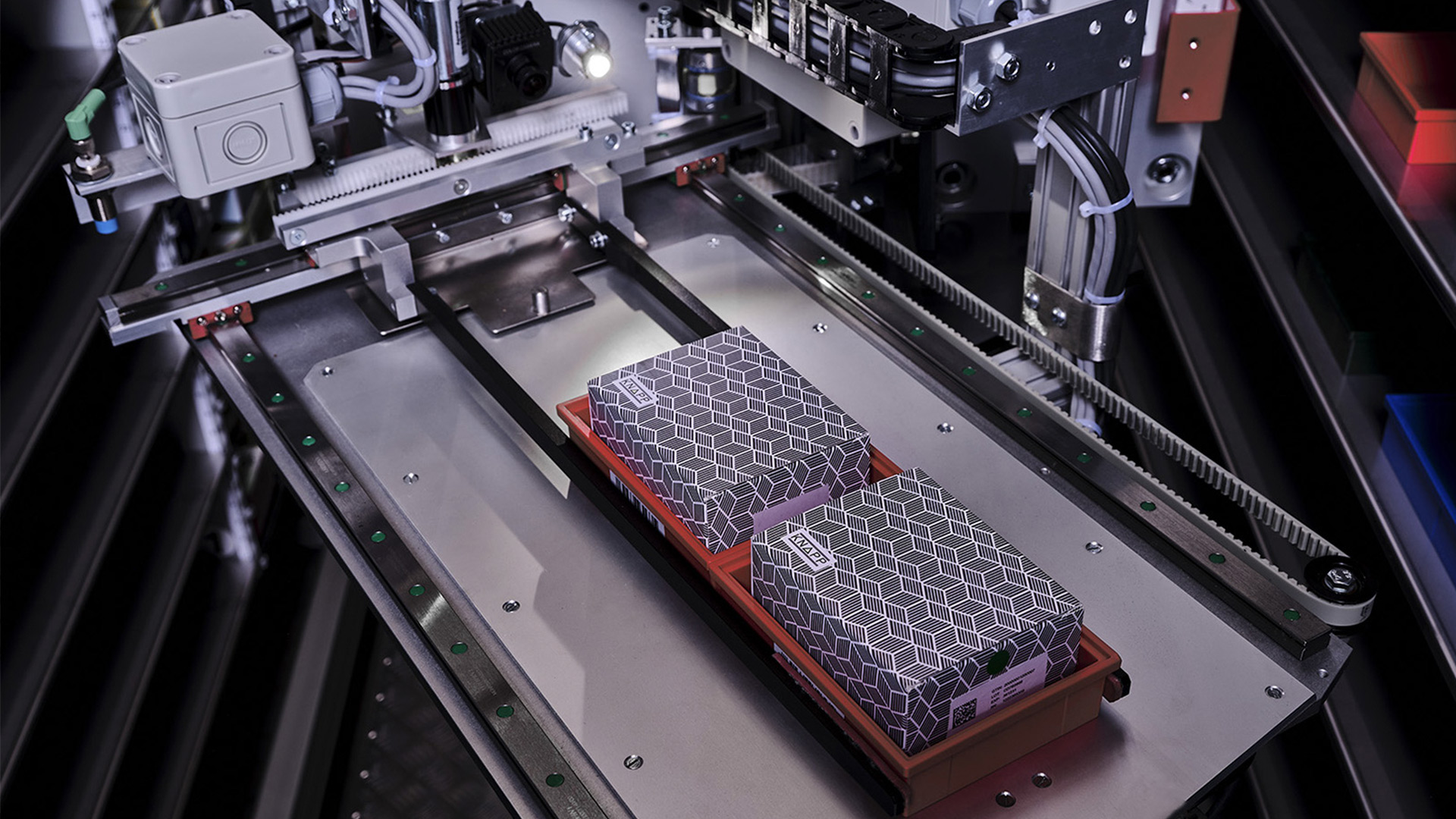

Ergonomic, intelligent work stations

Our work stations combine ergonomics, efficiency and quality. They utilize the goods-to-person principle, which means optimal order processing and satisfied employees. Work stations combined with an intelligent camera system ensure end-to-end quality control. Find out more about our products:

Automated mobile robots for increased flexibility

Our intelligent automated mobile robots allow you to design your logistics processes flexibly. They automate internal transport and efficiently connect different production areas.

Find out more about our autonomous mobile robots (AMRs):

Software for warehouse automation

The heart of any warehouse automation is its software. As a value chain tech partner, we offer all-in-one software solutions, intelligent fleet control software, resource planning software and much more. We cover processes with our KiSoft and SAP® EWM by KNAPP product lines as needed.

Learn more about our comprehensive software solutions:

Automated storage systems for efficient production processes

Whether automated small parts warehouses, storage robot systems, stacker cranes or buffer towers, we have the optimal logistics solution for every requirement. Our storage systems support processes such as picking, buffering, sequencing of both goods and orders as well as supplying work stations. Find out more about our smart solutions:

Automated storage and picking system for higher performance

The automated storage and picking system InduStore is an ideal solution for industrial applications, especially for stockpiling individual items, supplying production or storing spare parts. Discover more about the system:

Ergonomic, intelligent work stations

Our work stations combine ergonomics, efficiency and quality. They utilize the goods-to-person principle, which means optimal order processing and satisfied employees. Work stations combined with an intelligent camera system ensure end-to-end quality control. Find out more about our products:

Automated mobile robots for increased flexibility

Our intelligent automated mobile robots allow you to design your logistics processes flexibly. They automate internal transport and efficiently connect different production areas.

Find out more about our autonomous mobile robots (AMRs):

Software for warehouse automation

The heart of any warehouse automation is its software. As a value chain tech partner, we offer all-in-one software solutions, intelligent fleet control software, resource planning software and much more. We cover processes with our KiSoft and SAP® EWM by KNAPP product lines as needed.

Learn more about our comprehensive software solutions:

The gains for production logistics

Automating production logistics offers manufacturers many advantages:

Efficient processes

Intelligent integration

Perfectly timed production supply

Integration into existing infrastructure

Flexibility for process changes and growth

Error-free production and the best possible quality

References:

Our solutions for warehouse automation in manufacturing

Companies around the globe depend on collaboration with KNAPP. We help you optimize your production processes, storage space and in-house transport. Our solutions speak for themselves:

Terberg Benschop B.V.: New solution creates basis for future company growth

To handle the increasing number of orders, several processes at Terberg Benschop B.V. were centralized in one automated storage system. Picking orders are fulfilled for manufacturing, the assembly line, or for the shipping of spare parts. Supply is as needed and just in time.

Magna Spiegelsysteme: Optimizing supply to production and assembly

Thanks to the automated solution by KNAPP, Magna achieved faster availability of parts, a reduction in internal transport and hands-free warehouse operation. The foundation for all of this is the multifunctional shuttle system combined with autonomous mobile robots.

Fronius: AMRs provide flexible, automated pallet transport for production supply

The innovative Open Shuttle Fork has automated production supply and internal transport at Fronius. The new solution gives the company the necessary autonomy to flexibly make changes as needed and to manage both manual and automatic transport orders in the same system.

Knorr-Bremse: Process optimization thanks to customized system

Knorr-Bremse increased the performance of their small-parts warehouse by a factor of three. This was made possible by a multifunctional shuttle system combined with picking work stations and a conveyor system mounted to the ceiling. Discover more about the solution and how it efficiently covers the various processes.

Pankl Racing AG: Zero-error strategy covers all production processes

An automated small parts warehouse supplies Pankl’s assembly work stations according to the goods-to-person principle. Modern image recognition and processing technologies check each step of work, which results in error-free assembly and seamless traceability. Pankl’s manufacturing logistics is a textbook case in smart production.

Würth: Intelligent automation in logistics

Würth is using the very latest robot technologies at their warehouse. These technologies fully automate logistical processes ranging from storage to picking and shipping, including internal transport. We have partnered with Würth for many years, continually developing the technologies they use.

References:

Our solutions for warehouse automation in industry

Companies around the globe depend on collaboration with KNAPP. We help you optimize your production processes, storage space and in-house transport. Our solutions speak for themselves:

Terberg Benschop B.V.: New solution creates basis for future company growth

To handle the increasing number of orders, several processes at Terberg Benschop B.V. were centralized in one automated storage system. Picking orders are fulfilled for manufacturing, the assembly line, or for the shipping of spare parts. Supply is as needed and just in time.

Magna Spiegelsysteme: Optimizing supply to production and assembly

Thanks to the automated solution by KNAPP, Magna achieved faster availability of parts, a reduction in internal transport and hands-free warehouse operation. The foundation for all of this is the multifunctional shuttle system combined with autonomous mobile robots.

Fronius: AMRs provide flexible, automated pallet transport for production supply

The innovative Open Shuttle Fork has automated production supply and internal transport at Fronius. The new solution gives the company the necessary autonomy to flexibly make changes as needed and to manage both manual and automatic transport orders in the same system.

Knorr-Bremse: Process optimization thanks to customized system

Knorr-Bremse increased the performance of their small-parts warehouse by a factor of three. This was made possible by a multifunctional shuttle system combined with picking work stations and a conveyor system mounted to the ceiling. Discover more about the solution and how it efficiently covers the various processes.

Pankl Racing AG: Zero-error strategy covers all production processes

An automated small parts warehouse supplies Pankl’s assembly work stations according to the goods-to-person principle. Modern image recognition and processing technologies check each step of work, which results in error-free assembly and seamless traceability. Pankl’s manufacturing logistics is a textbook case in smart production.

Würth: Intelligent automation in logistics

Würth is using the very latest robot technologies at their warehouse. These technologies fully automate logistical processes ranging from storage to picking and shipping, including internal transport. We have partnered with Würth for many years, continually developing the technologies they use.

Global service network and reliable partner

Our International Customer Service looks after your logistics system – around the globe, around the clock, 365 days a year.

Discover more about our services, from seamless support to optimizing your system!

Warehouse automation for manufacturing –

our customers trust us:

Are you curious about our solutions for warehouse automation for manufacturing?

We’re happy to tell you more!

FAQ Warehouse Automation

The optimal degree of automation depends for the most part on the requirements, processes and goals specific to your company. There are various factors to consider: Is this a greenfield or a brownfield project? How large is the warehouse? Which goods are handled? What’s the throughput and the infrastructure of the location? KNAPP offers solutions that can be tailored to your sector, production logistics and growth targets. Find out more in our blog article The 5 Levels of Automation in Intralogistics >

KNAPP provides all-in-one software solutions from WMS (warehouse management system) to WCS (warehouse control system) down to individual machine control systems. These solutions cover all the steps of the value chain, can be integrated in existing IT environments and are compatible with conventional ERP and warehouse management systems. Find out more about KNAPP’s digital solutions >

What options are there for maintenance and support for automated logistics systems in manufacturing?

KNAPP provides a comprehensive maintenance system ranging from seamless system support, professional system monitoring and ongoing system support later on. We offer remote support in 8 languages 24/7, 365 days a year. Resident site engineers are on site providing technical system support and we have a global service network with 30 subsidiaries and 4 service partners. Find out more about our services here >

A typical automation project is implemented in 5 steps:

- Analysis and consultation

- Simulation and planning (or design and engineering)

- Project management and implementation

- Installation, startup and training

- Ongoing support from customer service

KNAPP supports their customers in all aspects during project implementation.

The project implementation period depends on the size of the project. After assessing the requirements, a precise schedule is drawn up. Smaller solutions such as AMR projects can generally be implemented within a few weeks, larger projects require several months.

It is worth looking into national and EU-wide funding programs for digitalization and automation. KNAPP can help with the project description and technical documentation for these programs.

KNAPP has successfully implemented many warehouse automation projects for manufacturing. Here is an overview of our best practice solutions: Logistics Case Studies: New Dimensions of Automation>

KNAPP implements projects of all sizes ranging from compact solutions for individual warehouse areas to fully automated logistics centers for global industrial companies.

KNAPP is headquartered in Hart bei Graz, Austria, where they also have their production site. Further production sites worldwide that also provide local service complement.

KNAPP offers solutions for containers, small load carriers, pallets, EUR-box pallets and special load carriers for specific industrial requirements.