mission: zero touch at LogiMAT 2024

Technology, innovation, and proximity to customers – as your value chain tech partner, these are all things we stand for. And at LogiMAT 2024 in Stuttgart, they are exactly the values we are demonstrating. We are excited to share these ideas – and, of course, our latest innovations – in person from March 19 to 21 at stands B01/03 in Hall 3. Additionally, we will be presenting our AMR solutions at stand C77 in Hall 6. Join us on our mission: zero touch to experience all the benefits of robotics in different areas of industry and dive into the world of KNAPP products and services.

Zero-touch fulfillment is a hot topic. In essence, it refers to highly automated order fulfillment that is completed without any manual intervention, and it has the potential to help mitigate a number of current economic challenges. As warehousing space becomes harder to find and storage costs surge, it is obvious that automation needs to happen quickly and that employees need to be doing tasks that put their abilities to good use.

With these factors in mind, zero-touch fulfillment is a complex scenario. So we asked ourselves: Where does zero-touch fulfillment begin? Where can you make the most of it? We’ve grouped a few examples by topic to show you different options for overcoming current challenges, whether your goal is boosting your performance, optimizing your processes, taking the load off your employees or becoming more sustainable. As a dedicated partner, we’d now like to show how you can profit from our mission: zero touch and from zero-touch fulfillment.

Flawless teamwork with zero-touch fulfillment:

automatic pocket loading with Pick-it-Easy Robot and AutoPocket

The centerpiece of our stand at the trade fair is our sensational live exhibit. The great combination of AutoPocket with our Pick-it-Easy Robot, shows what mission: zero touch is really all about – different technologies working together in perfect harmony to optimize processes and reduce inefficient and expensive process steps. Using AI-based object detection and grip point calculation, our Pick-it-Easy Robot picks different types of items directly into AutoPocket, which then deposits the goods into containers precisely while still moving full speed ahead. To tap your warehouse’s full potential, consider the OSR Shuttle Evo automated small parts warehouse, which can be integrated seamlessly into this zero-touch solution.

Automatically loading sorter pockets is an especially formidable task for omnichannel and e-commerce fulfillment. This combination sets new standards for efficiency thanks to AutoPocket’s ability to open automatically and deposit items while moving at full speed. See for yourself how different innovative technologies are even stronger together!

Have we sparked your interest?

Come to our lecture:

“mission: zero touch – robots as a recipe against staff shortages and cost pressure”

Presented by: Jürgen Puchta, Alexander Holzinger

Wednesday, March 20 | Hall 7, Forum North | 11:00–11:20 a.m. | German

Mission control center:

everything in sight with intelligent software

The brain behind our exhibit is our perfectly coordinated software. In contemporary intralogistics, software is tightly linked with machines and robots as well as service and consulting. These three elements – software, machines and service – can only reach their full potential and add significant value when working together.

Our integrated intelligence approach integrates each discipline to provide you with an all-in-one solution. Experience how it all comes together, live at LogiMAT 2024, where our software solutions KiSoft and SAP EWM by KNAPP, combine to form a veritable software cockpit. Or find out more about our warehouse management system, KiSoft WMS, or our warehouse control system, KiSoft WCS, and see how our Digital Services interact to your advantage. Which digital service solutions make up our portfolio? Here’s an overview.

More information about intelligent networks and sustainability

Go deeper at our lecture:

“Employing AI & big data to advance from optimisation to sustainability”

Presented by: Mario Berger, Hansjürgen Walter

Wednesday, March 20 | Hall 7, Forum North | 1:00–1:20 p.m. | English

Reading tip: Sustainability at KNAPP

Digital Services:

make the right decisions for using your data to generate value

What if you could use existing system data to find out today that a system component will need replacing in two weeks – and have the optimal maintenance window already planned by our digital solutions? Our Digital Services make all that and more a reality. They also provide support at product launch, when increasing picking performance and when preparing for the next peak. Find out about our digital solutions in our software cockpit at this year’s LogiMAT and see for yourself how they interconnect and synergize.

For example, KiSoft CMMS,short for KiSoft Computerized Maintenance Management System, keeps maintenance management running smoothly, while our labor-management-system helps you schedule your personnel proactively and efficiently. Rounding out the trio is KiSoft Analytics which transforms mountains of data into structured information and depicts it clearly on standardized, individually customizable dashboards. The result: You get an overview of all data in your system and the ideal basis for making decisions.

Along with our digital solutions, our service portfolio offers proactive and preventative solutions and all the services your warehouse needs in ongoing operation. And if your business model should change, we’ll support you in adapting your system design and determine what needs to be modernized together with you, retrofitting to keep your system running at top levels of sustainability and performance.

Master data recording made easy

with MultiScan and KiSoft Genomix

Every automation solution depends on well-maintained master data to work efficiently, from storage systems to picking robots. Manually recording item master data, however, requires a significant amount of time and is prone to errors.

There is another way! At LogiMAT 2024, our MultiScan and KiSoft Genomix team up to show how master data recording can be quick, easy and accurate. MultiScan easily and precisely captures logistical data, such as the volume or weight of items, as well as EAN barcodes and much more.

KiSoft Genomix makes it simple and intuitive to record master data for automation. Targeted questions guide employees through the recording process, after which the software derives and digitalizes attributes such as stacking data, center of gravity or tilting behavior. All of this information is critical for the smooth operation of the warehouse. It is exactly what a robotic system needs to process and handle various types of items with precision.

InduStore: a small parts warehouse powerhouse

Manually picking orders using pick lists requires a lot of time and is prone to errors. At the same time, finding and retaining employees is becoming increasingly difficult. Are you wondering how to keep your storage and logistics processes efficient and error-free with the personnel you have as incoming orders continue to grow?

The automated small parts warehouse InduStore has the answer. It’s perfect as a shipping or spare parts warehouse, for supplying production, storing consumable goods fully automatically or for stockpiling individual items.

At LogiMAT, you can see firsthand just how flexible and scalable InduStore is. Our exhibit includes a photorealistic digital simulation that lets you configure your very own custom InduStore and adapt it to suit your needs and even lets you combine multiple InduStores in a custom system. Don’t miss taking a digital look inside the small parts warehouse – it’s an absolute must!

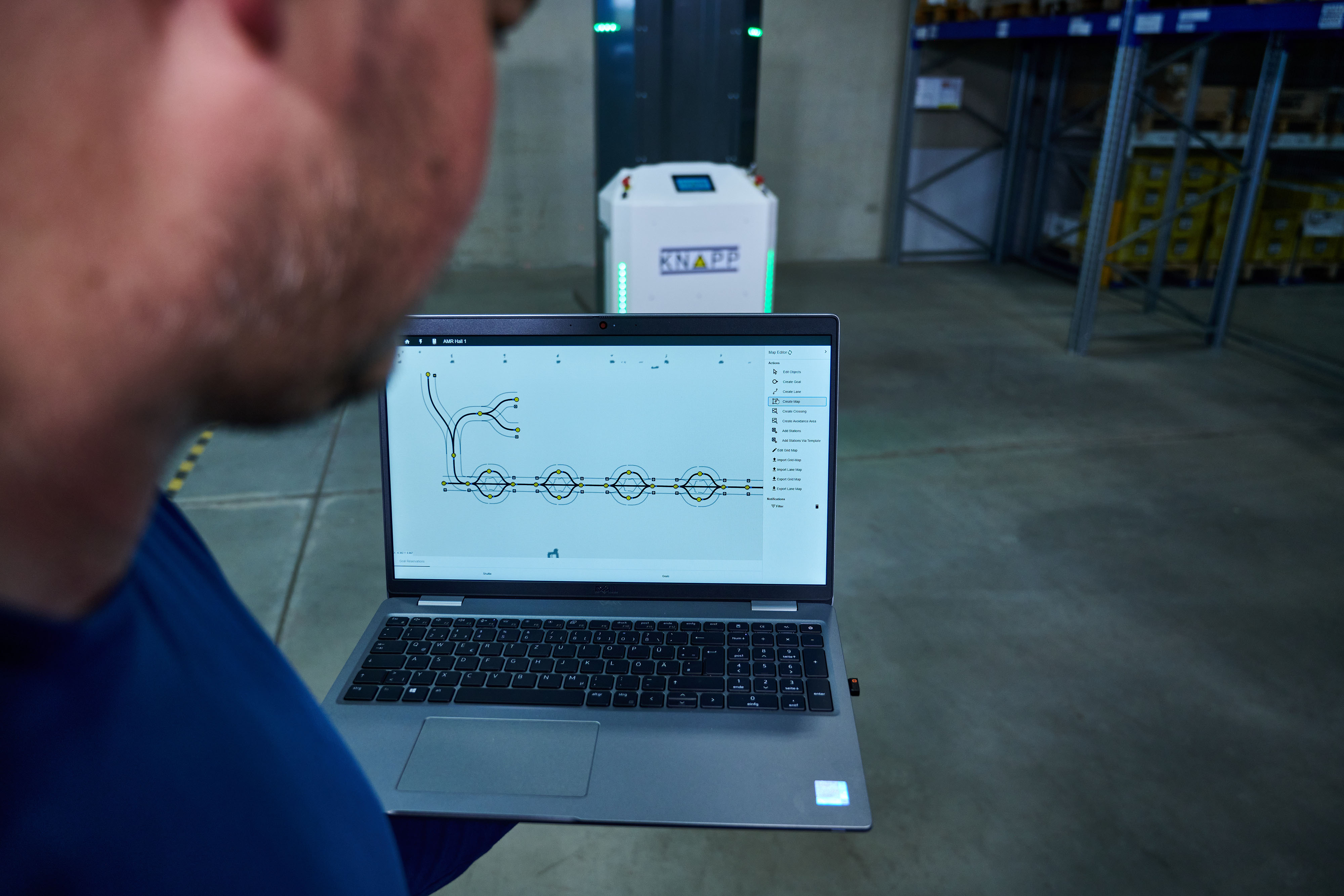

Open Shuttles: intelligent robotics

for automated and flexible goods transport

Our Open Shuttles are autonomous mobile robots (AMRs) that automate the internal transport of goods easily, flexibly and efficiently. They offer either an alternative or supplement to classic conveyor systems and move about freely and autonomously. Open Shuttles can be used to transport containers, cartons, trays or even pallets and are therefore ideal for transporting goods from the goods-in area to the storage system, cross-docking, and supplying work stations. A particular highlight at our stand is our Open Shuttle Fork, which was awarded 2023 Product of the Year and the Best of Industry Award 2023. The AMR shows just how flexible, space-effective and efficient transporting pallets can be.

At the stand, we’ll also be presenting an AI-supported camera system for checking empty containers in logistics applications. The innovative system checks containers not only for leftover items, but can also identify all types of damage so containers can be diverted out efficiently. With this technology, you can save significant amounts of time and optimize shipping costs in returns processing, goods-in and goods-out, and in container management.

KiSoft FCS: the software

that lets you keep track of your entire fleet

A reliable, efficient fleet management system is essential for any company with a fleet of warehouse vehicles. Our fleet management software KiSoft FCS, puts you in charge of your entire fleet at all times.

The fleet control system is the smart way to control and coordinate different vehicles and manage transport orders. With just a few clicks, you can make changes to your processes and layout. The fleet control system can be integrated seamlessly into both KNAPP systems and other Host systems. It can also be used as a stand-alone system. Another highlight is the KiSoft FCS digital twin, which can be used to simulate and test changes in advance.

Interested in the twin?

Get the details at our lecture:

“Digital Twin in the Loop: Improving the quality of AMR projects through simulation and emulation”

Presented by: Thomas Ulz

Thursday, March 21 | Hall 8, Forum South | 12:30–12:50 p.m. | German

Have we sparked your interest?

If you would like to see leading automation solutions for yourself, come see us at LogiMAT 2024 in Stuttgart. Make your appointment today to consult with our experts directly at our stand. Our colleagues will be very happy to introduce you to our latest developments!

LogiMAT in Stuttgart, March 19–21, Hall 3, stands B01/B03 and Hall 6, stand C77